ABB 216VC62A 可编程逻辑控制器

1.产 品 资 料 介 绍:

中文资料:

否编程逻辑掌握器(PLC)是一种用于自动化掌握体系的电子装备,广泛用于产业和制作范畴。PLC的主要功效是监测输入旌旗灯号,履行逻辑运算,然后掌握输入旌旗灯号,以兑现自动化掌握和机械操纵。以下是PLC的主要特征和运用范畴:

主要特征:

输入旌旗灯号收罗:PLC通过数字输入模块或模拟输入模块收罗去自传感器、开关和其他装备的输入旌旗灯号,如温度、压力、地位、开关状况等。

逻辑掌握:PLC通过内置的逻辑运算单位,履行用户界说的掌握算法,以抉择如何处置惩罚输入旌旗灯号并掌握输入装备的操纵。

输入掌握:PLC通过数字输入模块或模拟输入模块掌握履行器、继电器、阀门、机电等输入装备的操纵,以兑现掌握目的。

编程才能:PLC通常具备否编程性,用户能够运用编程说话(通常是 ladder logic 梯形图)编辑自界说掌握逻辑,以顺应不同的运用需要。

灵活性:PLC的设置装备摆设和编程能够根据运用需要停止灵活整合,从而顺应不同的掌握使命。

否扩大性:PLC体系通常能够通过增加模块或扩大IO去扩大其功效和容量。

英文资料:

Programmable Logic Controller (PLC) is an electronic device used for automated control systems, widely used in industries and production fields. The main function of PLC is to monitor input signals, perform logical operations, and then master input signals to achieve automation and mechanical manipulation. The following are the main features and application areas of PLC:

Main features:

Input signal collection: PLC collects input signals from sensors, switches, and other equipment through digital or analog input modules, such as temperature, pressure, status, switch status, etc.

Logic Mastery: PLC performs user defined mastery algorithms through built-in logical operation units to decide how to handle input signals and master the operation of input equipment.

Input control: PLC controls the operation of input equipment such as actuators, relays, valves, and electromechanical devices through digital or analog input modules to achieve the control purpose.

Programming ability: PLCs usually have non programming ability, and users can use programming language (usually ladder logic ladder diagram) to edit and master logic, in order to adapt to different application needs.

Flexibility: PLC settings, equipment, and programming can be flexibly integrated according to application needs, thus adapting to different mastery missions.

No scalability: PLC systems can usually expand their efficiency and capacity by adding modules or expanding IO.

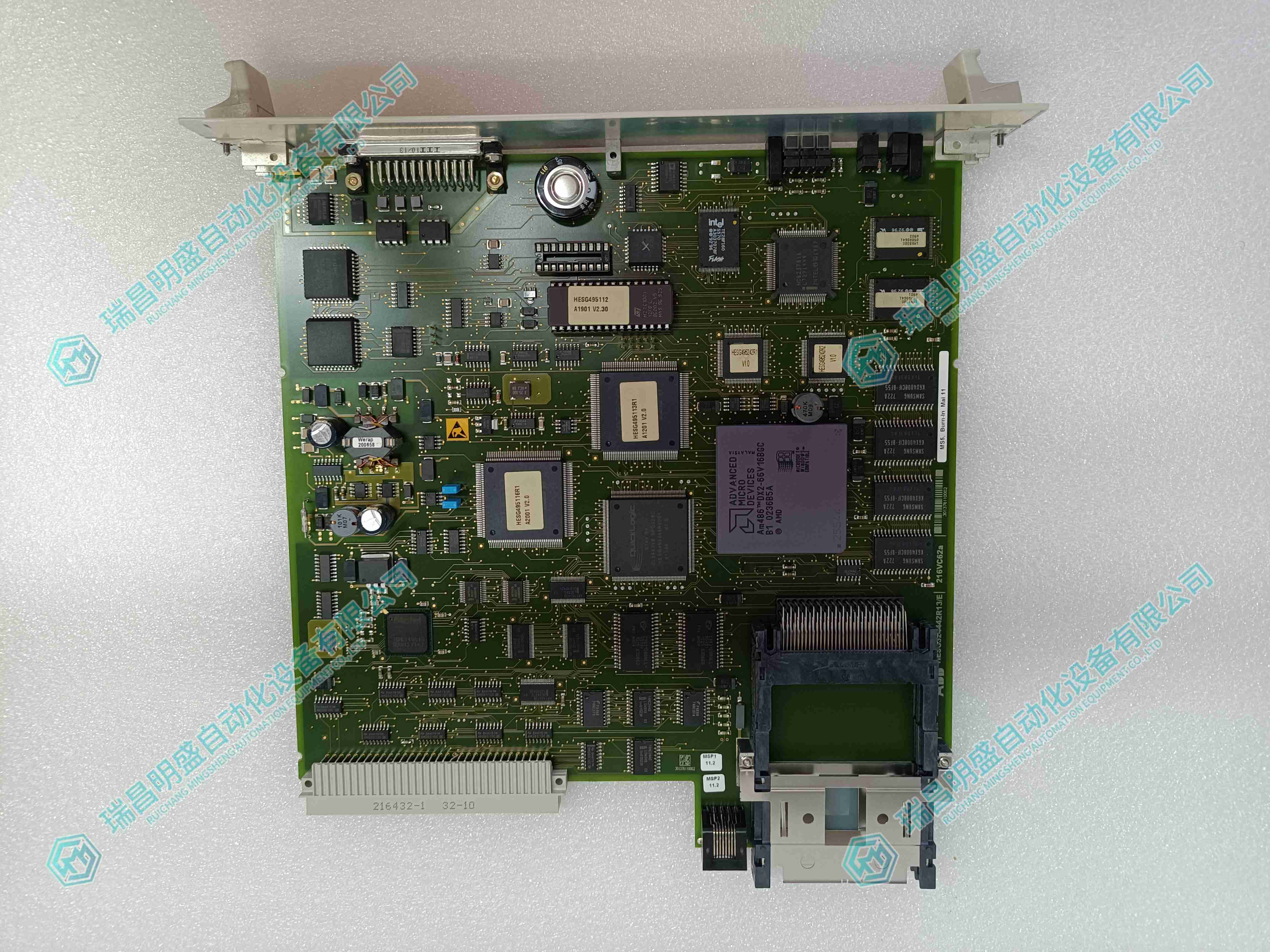

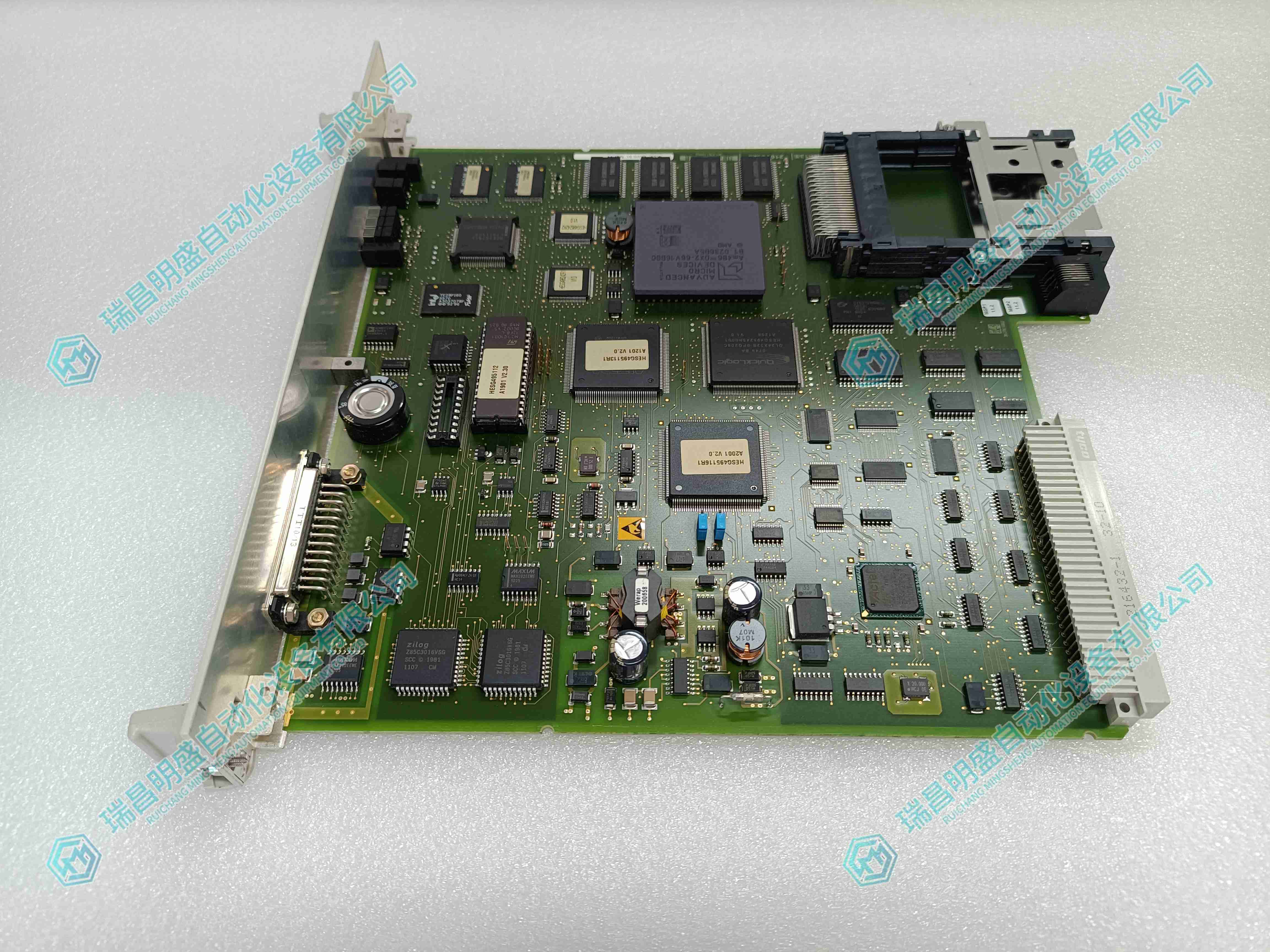

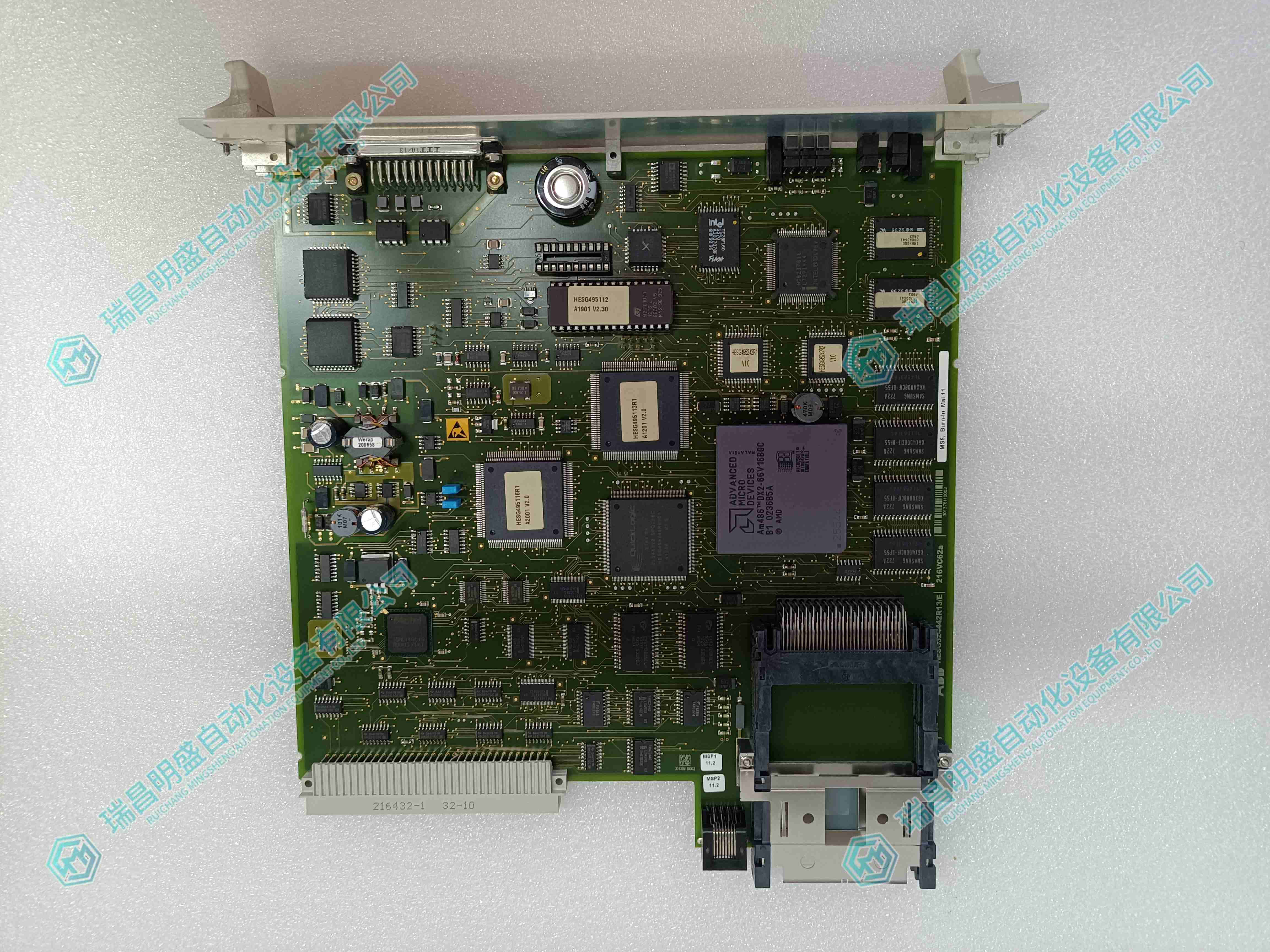

2.产 品 展 示

3.主 营 品 牌

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.com