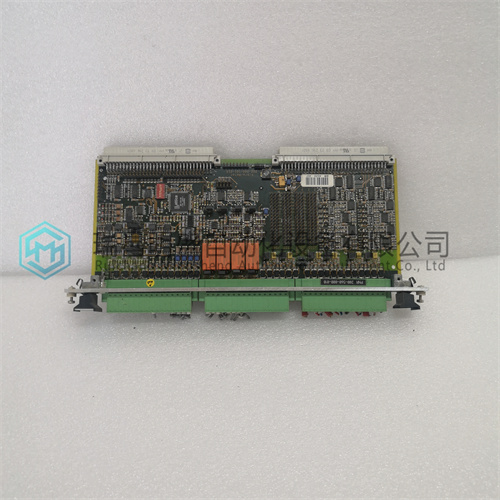

Vibro-meter 200-560-000-018 200-560-101-015 VM600 IOC4T模块

1.产 品 详 情 资 料:

Vibro-meter VM600 IOC4T是一种振动监测系统,可用于监测工业设备的振动和温度,以便诊断和预测机器故障。下面是该产品的特点和使用方法:

特点:

Vibro-meter VM600 IOC4T采用4通道的数据采集和分析系统,能够对多个设备进行同时监测和分析。

可以测量不同频率范围内的振动信号,并能够对其进行分析,如峰值、有效值、峭度等指标。

支持多种振动传感器类型,包括加速度、速度和位移传感器。

可以连接到计算机进行数据传输和分析,也可以通过网络进行远程监控和诊断。

支持多种报警和通知方式,如声音、光线、邮件等,方便用户及时得知设备状态的变化。

使用方法:

将VM600 IOC4T安装在要监测的设备上,并将振动传感器连接到系统上。

连接电源并按照说明书进行初始化设置,包括选择采样频率、设置报警阈值等。

开始监测设备的振动和温度信号,并观察系统的数据分析结果。

如果系统检测到设备异常情况,系统会自动报警或通知用户,用户需要及时采取相应措施进行维护和修理。

用户可以通过计算机或网络远程访问系统,查看实时监测数据和分析结果,也可以进行数据分析和生成报告。

Vibro-meter VM600 IOC4T is a vibration monitoring system that can be used to monitor the vibration and temperature of industrial equipment in order to diagnose and predict machine failures. The following are the features and usage methods of this product:

characteristic:

Vibro-meter VM600 IOC4T uses a 4-channel data acquisition and analysis system that can simultaneously monitor and analyze multiple devices.

It can measure and analyze vibration signals in different frequency ranges, such as peak value, effective value, kurtosis, and other indicators.

Supports a variety of vibration sensor types, including acceleration, velocity, and displacement sensors.

It can be connected to a computer for data transmission and analysis, as well as remote monitoring and diagnosis through the network.

Support multiple alarm and notification methods, such as voice, light, email, etc., to facilitate users to promptly learn about changes in device status.

usage method:

Install the VM600 IOC4T on the device to be monitored and connect the vibration sensor to the system.

Connect the power supply and perform initialization settings according to the instructions, including selecting a sampling frequency, setting alarm thresholds, and so on.

Start monitoring the vibration and temperature signals of the equipment, and observe the data analysis results of the system.

If the system detects an abnormality in the equipment, the system will automatically alarm or notify the user, and the user needs to take corresponding measures for maintenance and repair in a timely manner.

Users can remotely access the system through a computer or network to view real-time monitoring data and analysis results, as well as perform data analysis and generate reports.

2.今 日 产 品 展 示

3. 主 营 品 牌

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.com