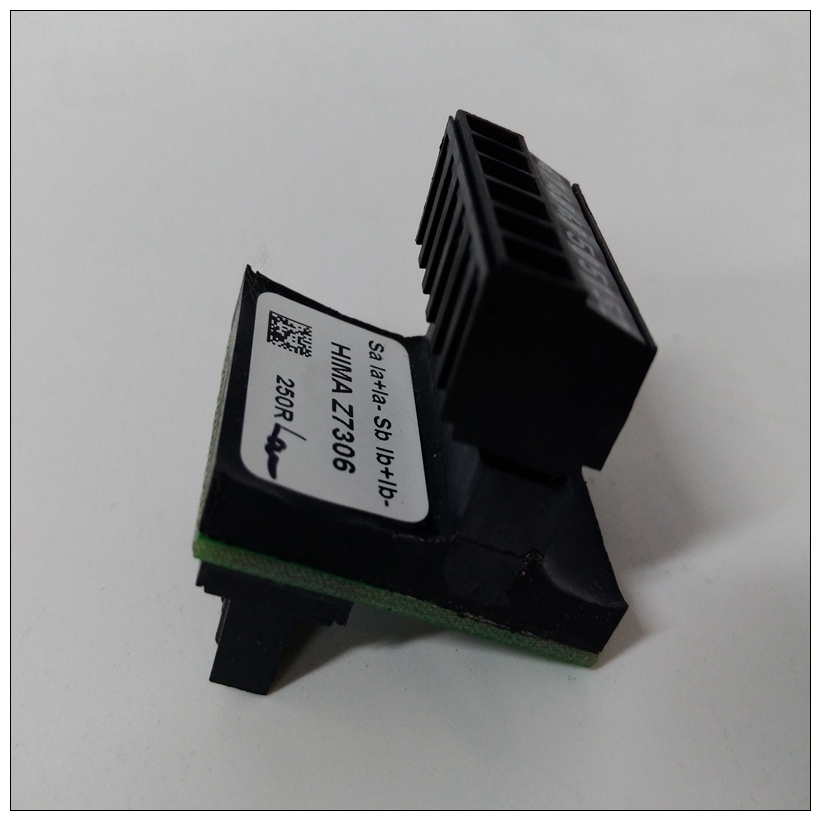

HIMA F8621A系统模块卡件

5: RX3i系统使用一个通用背板和一个扩展背板1.5.2使用多个扩展和远程背板以下两个示例系统彼此相似,但背板之间的距离不同。左侧的示例包括两个RX3i扩展背板和一个Series 90-30扩展背板。扩展背板可以是RX3i(IC694)和Series 90-30(IC693)扩展背板的任意组合。系统中的I/O模块可以是RX3i和Series 90-30模块的任意组合。在右侧的示例中,两个背板的安装必须超出扩展系统的15米(50英尺)限制。在这些位置使用两个Series 90-30远程背板。两个示例系统的所有其他功能都相同,包括其I/O模块。PACSystems*RX3i系统手册第2节GFK-2314T 2019年9月简介18 RX3i扩展背板IC694CHS398 RX3i通用背板IC695CHS012 RX3i扩充背板IC694C HS392系列90-30扩充背板IC691CHS392 I/O端接插头IC693ACC307最大电缆长度:15米(50英尺)图6:使用多扩展背板的RX3i系列90-30远程背板IC693CHS399 RX3i通用背板IC695CHS012 RX3i扩展背板IC694CHS392系列90-30远程背板IC693CHS393 I/O终端插头IC693ACC307最大电缆长度:15米(50英尺)最大电缆长度为213米(700英尺)图7:使用扩展和远程背板的RX3i系统PACSystems*RX3i《系统手册》第3节GFK-2314T 2019年9月安装19第2节:安装本章提供安装PACSystems RX3i设备的一般说明。▪ 安装前检查▪ 系统布局指南▪ 附件▪ 系统接线▪ 系统接地▪ 系统安装有关系统安装的其他信息,请参阅以下内容:▪ 第3章,背板,背板尺寸图▪ 第4章,电源,电源规格和接线图▪ 模块接线图和规范的第5章至第16章▪ 第17章了解一些高密度模块的接线板、接线板快速连接系统(TBQC)和互连电缆的信息。▪ 通用标准信息附录A▪ 附录B关于计算散热的信息▪ 附录C有关电缆夹紧组件2.1安装前检查的信息收到RX3i设备后,仔细检查所有装运集装箱是否损坏。如果系统的任何部分损坏,请立即通知承运人。损坏的运输集装箱应保存作为承运人检查的证据。作为收货人,您有责任向承运人登记运输过程中发生的损坏索赔。但是,如果有必要,我们将与您充分合作。RX3i设备开箱后,记录所有序列号。如果您在保修期内需要联系客户服务,则需要序列号。如果需要运输或装运系统的任何部分,则应保存所有装运集装箱和所有包装材料。确认系统的所有组件均已收到,并且与您的订单一致。如果收到的系统与您的订单不一致,请联系客户服务部。如果您需要技术帮助,请联系技术支持。有关电话号码和电子邮件地址,请参阅联系信息。PACSystems*RX3i系统手册第3节GFK-2314T 2019年9月安装20 2.2系统布局指南良好的布局有助于最大限度地减少系统工作人员触电的机会。它使维护技术人员能够方便地访问设备进行测量、加载软件、检查指示灯、拆除和更换模块等。它还使在进行故障排除时更容易追踪布线和定位部件。此外,适当的系统布局可促进良好的散热,并有助于消除系统中的电气噪声。过热和噪音是电子元件故障的两个主要原因。§将RX3i设备放置在远离产生大量热量的其他部件的位置,如变压器、电源或功率电阻器。§将RX3i设备置于远离产生电气噪声的部件(如继电器和触点)的位置。§将RX3i设备放置在远离高压部件和电线的位置,如断路器和易熔断开器、变压器和电机电线。§将设备放置在方便的位置,使技术人员能够合理地维护系统。

5: RX3i System using One Universal Backplane and One Expansion Backplane 1.5.2 Using Multiple Expansion and Remote Backplanes The next two example systems are similar to each other except for the distance between the backplanes. The example on the left includes two RX3i Expansion Backplanes and a Series 90-30 Expansion Backplane. The Expansion Backplanes can be any combination of RX3i (IC694) and Series 90-30 (IC693) Expansion Backplanes. I/O modules in the system can be any combination of RX3i and Series 90-30 modules. In the example on the right, two of the backplanes must be installed beyond the 15 m (50-ft) limit of an Expansion system. Two Series 90-30 Remote Backplanes are used in those locations. All other features of the two example systems are the same, including their I/O modules. PACSystems* RX3i System Manual Section 2 GFK-2314T Sept. 2019 Introduction 18 RX3i Expansion Backplane IC694CHS398 RX3i Universal Backplane IC695CHS012 RX3i Expansion Backplane IC694CHS392 Series 90-30 Expansion Backplane IC693CHS392 I/O Terminator Plug IC693ACC307 Maximum Cable Length: 15 meters (50 feet) Figure 6: RX3i System using Multiple Expansion Backplanes Series 90-30 Remote Backplane IC693CHS399 RX3i Universal Backplane IC695CHS012 RX3i Expansion Backplane IC694CHS392 Series 90-30 Remote Backplane IC693CHS393 I/O Terminator Plug IC693ACC307 Maximum Cable Length: 15 meters (50 feet) Maximum Cable Length: 213 meters (700 feet) Figure 7: Rx3i System using Expansion and Remote Backplanes PACSystems* RX3i System Manual Section 3 GFK-2314T Sept. 2019 Installation 19 Section 2: Installation This chapter provides general instructions for installing PACSystems RX3i equipment. ▪ Pre-Installation Check ▪ System Layout Guidelines ▪ Enclosures ▪ System Wiring ▪ System Grounding ▪ System Installation For additional information about system installation, refer to the following: ▪ Chapter 3, Backplanes, for backplane dimension diagrams ▪ Chapter 4, Power Supplies, for power supply specifications and wiring diagrams ▪ Chapters 5 through 16 for module wiring diagrams and specifications ▪ Chapter 17 for information about terminal blocks for some higher-density modules, the Terminal Block Quick Connect System (TBQC) and interconnect cables. ▪ Appendix A for general standards information ▪ Appendix B for information about calculating heat dissipation ▪ Appendix C for information about the Cable Clamping Assembly 2.1 Pre-Installation Check Upon receiving your RX3i equipment, carefully inspect all shipping containers for damage. If any part of the system is damaged, notify the carrier immediately. The damaged shipping container should be saved as evidence for inspection by the carrier. As the consignee, it is your responsibility to register a claim with the carrier for damage incurred during shipment. However, we will fully cooperate with you, should such action be necessary. After unpacking the RX3i equipment, record all serial numbers. Serial numbers are required if you should need to contact Customer Care during the warranty period. All shipping containers and all packing material should be saved should it be necessary to transport or ship any part of the system. Verify that all components of the system have been received and that they agree with your order. If the system received does not agree with your order, contact Customer Care. If you need technical help, contact Technical Support. For phone numbers and email addresses, refer to Contact Information. PACSystems* RX3i System Manual Section 3 GFK-2314T Sept. 2019 Installation 20 2.2 System Layout Guidelines A good layout helps minimize the chance of electrical shock to personnel working on the system. It lets maintenance technicians easily access the unit to make measurements, load software, check indicator lights, remove and replace modules, etc. It also makes it easier to trace wiring and locate components while troubleshooting. In addition, proper system layout promotes good heat dissipation and helps eliminate electrical noise from the system. Excess heat and noise are two major causes of electronic component failure. § Locate RX3i equipment away from other components that generate a lot of heat, such as transformers, power supplies, or power resistors. § Locate RX3i equipment away from components that generate electrical noise such as relays and contacts. § Locate RX3i equipment away from high-voltage components and wiring, such as circuit breakers and fusible disconnects, transformers, and motor wiring. § Locate equipment at a convenient level that allows technicians reasonable access for maintaining the system.