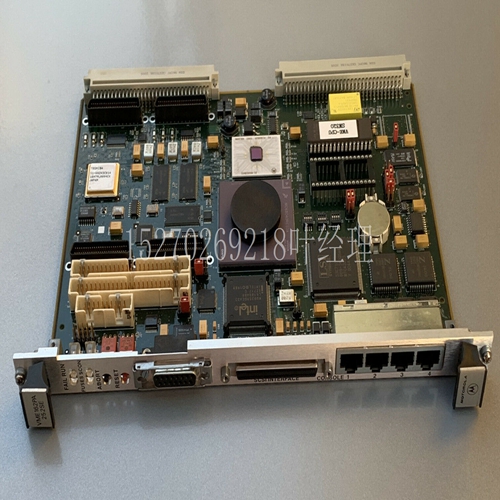

MVME162-521A PLC工控备件

注意连接器设计为在电机安装期间旋转到固定位置,并保持在该位置,无需进一步调整。不要多次旋转连接器,也不要使用工具或过度用力旋转连接器。过度旋转或用力会损坏连接器密封,降低电机的国际防护等级,如第页规范所述。注意仅对电机连接器和电缆插头施加力。不要对从电缆插头伸出的电缆施加力。不要使用工具例如钳子和虎钳旋转连接器。系列或更小框架尺寸的低惯量无刷伺服电机年月安装电机按照以下步骤安装电机。为电机提供足够的间隙散热片和气流,使其保持在的工作温度范围内。除非强制冷却空气穿过电机,否则不要封闭电机,并使其他发热设备远离电机。散热器要求在第页规范的脚注中列出。验证应用的轴向和径向轴负载不超过第页电机负载力额定值中列出的值。将电机与电缆连接放置在电机下方。有关正确电机和电缆定位的视觉参考,请参阅第页的拆卸轴盖。正确安装和对齐电机电机包括一个安装导向器,用于在机器上对齐电机。当轴键与连接器对齐时,线编码器上出现索引脉冲。确保皮带负载在电机限制范围内,并且所有皮带和滑轮正确对齐。遵循齿轮箱滑轮或其他电机附件的制造商建议。注意如果在安装联轴器和皮带轮期间对轴施加剧烈冲击,可能会损坏电机轴承和反馈装置。在安装或拆卸过程中,不要用工具敲击联轴器或皮带轮。注意电机的外表面在运行过程中可能会达到的高温。采取预防措施,防止意外接触热表面。选择电机配合连接和电缆时,应考虑电机表面温度。系列或更小框架尺寸的低惯量无刷伺服电机年月连接电机电缆安装电机后,按照以下步骤连接反馈和动力制动电缆。

Note that the connector is designed to rotate to a fixed position during motor installation and remain in that position without further adjustment. Do not rotate the connector more than once, nor use tools or excessive force to rotate the connector. Excessive rotation or force can damage the connector seal and reduce the international protection level of the motor, as described in the specifications on page. Note that only force is applied to the motor connector and cable plug. Do not apply force to the cable protruding from the cable plug. Do not use tools such as pliers and vises to rotate the connector. Low inertia brushless servo motor with frame size of series or smaller shall be installed according to the following steps. Provide the motor with enough clearance, radiator and air flow to keep it within the operating temperature range of. Do not close the motor and keep other heating equipment away from the motor unless forced cooling air passes through the motor. The radiator requirements are listed in the footnote to the specification on page. Verify that the applied axial and radial shaft loads do not exceed the values listed in Motor Load Force Ratings on page. Place the motor and cable connection under the motor. For a visual reference to correct motor and cable positioning, refer to Removing the Shaft Cover on page. Proper mounting and alignment of the motor The motor includes a mounting guide for aligning the motor on the machine. When the axis key is aligned with the connector, the index pulse appears on the wire encoder. Make sure that the belt load is within the limits of the motor and that all belts and pulleys are correctly aligned. Follow the manufacturer's recommendations for gearbox pulleys or other motor accessories. Note that if severe impact is applied to the shaft during the installation of the coupling and pulley, the motor bearing and feedback device may be damaged. Do not knock the coupling or pulley with tools during installation or removal. Pay attention to the high temperature that the outer surface of the motor may reach during operation. Take precautions to prevent accidental contact with hot surfaces. The motor surface temperature shall be considered when selecting the motor mating connection and cable. Low inertia brushless servo motor of series or smaller frame size shall be connected with motor cable. After installing the motor, connect the feedback and power brake cables according to the following steps.