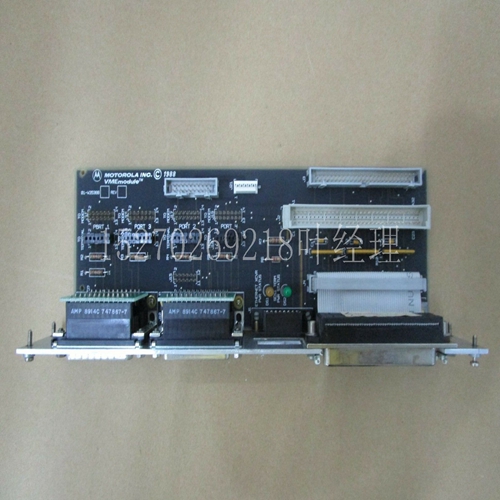

MVME162-723机器人模块卡件

称重约规格变化摘要本包含下表所示的新信息和更新信息。环境规范本表为页面提供了符合性声明证书和其他认证详细信息的环境规范。根据和第号标准,危险场所使用的列出的工业控制设备额定值级,组外壳类型额定值符合和寿命至半亮度时小时分钟背光功耗典型触摸屏模拟电阻驱动额定值万次按压操作力克模拟电阻驱动定值百万次按压操作压力克按下操作力克键盘个功能键应用程序。电气主机端口型输入电压时为端子规格技术规格端子英寸和英寸属性英寸。触摸英寸。触摸键盘触摸目录号末尾的添加,订购不带徽标和产品标识的终端,例如。操作员输入触摸加菜单导航按钮触摸加菜单菜单导航按钮触加菜单导航键显示类型彩色薄膜晶体管液晶显示器显示尺寸,对角线英寸。英寸。英寸。宽屏幕视图为英寸毫米显示分辨率纵横比:::色深位彩色图形色典型亮度背光发光二极管,不可更换寿命至半亮度时小时分钟背光功耗典型触摸屏模拟电阻驱动额定值万次按压操作力克键盘个功能键,数字键盘和导航键直流功耗最大最大时为最大值直流时为最大值线路频率电源支持和电源直流供电端子支持安全超低电压和保护性超低电压电源,如。编号支持和直流电源支持或电源机械重量约尺寸约毫米×英寸英寸切口尺寸约毫米英寸毫米英寸。典型的浪涌电流线路频率电源支持和电源直流供电端子支持安全超低电压和保护性超低压电源,如。编号支持和直流电源支持或电源机械重量约尺寸约毫米英寸英寸切口尺寸约毫米英寸毫米英寸终端规格产品尺寸该表提供了终端平台的产品尺寸。图中所示的英寸触摸和带触摸设备的组合键盘用于说明目的。所有其他端子尺寸看起来相似。端子尺寸所示型号为英寸端子尺寸端子尺寸输入类型高度宽度英寸总深度安装深度英寸。按键触摸触摸英寸。触摸英寸。按键头英寸。触摸英寸。按键触摸触摸英寸。触摸当安装在窗格中时,挡板前部距离挡板前部的距离小于毫米英寸。年月终端规范环境使用环境为终端平台创建应用程序。此环境包括以下主要组件,您可以在该应用程序中为特定的终端创建和设计项目,并在中部署。电源和电源接线盒类别。编号描述数量导轨电源,输出电压,导轨供电,输出电源,导轨电源,针交流电源接线端子针直流电源接线端子年月端子规格其他资源这些文档包含有关相关产品的更多信息。您可以查看或下载,网址为://要订购技术文件的纸质副本,请联系当地经销商或销售代表。安装硬件类别。编号描述数量目录编号安装杆使用*电缆绳索长度,夹具张紧器和吊环螺栓数量描述目录编号钢替换弹簧不锈钢替换弹簧产品选择附件*注包括拉伸弹簧。年月运动配件规范技术规范接口电缆应用安全配置和网络模块。用于制作您自己的电缆年月运动配件规格薄型连接器套件组件薄型连接器套件设计用于和驱动器和模块。使用此表确定反馈或连接器的薄型连接器套件。尺寸薄型连接器套件目录号重要事项下面列出的飞线兼容电缆需要连接器套件来完成与驱动器的反馈和连接。猫编号说明电缆兼容性电机反馈用薄型连接器套件公头,。与任何模块或驱动器以及具有增量或高分辨率反馈的兼容电机配合使用。不包括与高分辨率电机和位编码器一起使用所需的电池目录号。用于电机反馈公头,和公头的薄型连接器套件。与任何模块以及具有增量或高分辨率反馈的兼容电机一起使用。不包括与一起使用所需的电池目录号客户提供的用薄型连接器套件公头,。室温和下的和如图所示。合金的低周疲劳数据。合金的优异蠕变断裂强度如图中的参数图所示。合金合金和合金失效循环总轴向应变范围,图。合金和在下的低周疲劳强度。合金合金和合金失效循环总轴向应变范围,图。下合金和的低周疲劳强度。蠕变率,图合金和的典型蠕变强度。合金&表合金的代表性断裂强度值温度千磅/平方英寸断裂寿命,图。合金和参数**,其中温度单位,断裂寿命单位小时图。合金锅炉和压力容器规范合金的蠕变断裂强度已根据美国机械工程师协会的锅炉与压力容器规范获得批准。动力锅炉的建造规则在第节中定义,压力容器的建造规则则在第七节第部分和第部分中定义。第二节材料第部分性能表中列出了第节和第节第节建造中合金的设计应力值。规范案例也涉及第节的施工。允许在以下的温度下施工。。生产和合金产品以优化其高级级结构,与第二节材料第部分性能表中的相同。。的耐内氧化。合金&循环暴露时间,重量变化,合金合金和图。下的循环氧化试验结果。表是下小时渗碳试验的结果,将和合金与其他一些具有高抗渗碳性的合金进行了比较。大气由的甲烷和的氩气组成。表氢加甲烷合金重量合金合金合金型不锈钢表氢加甲烷合金重量小时气体渗碳试验结果合金型不锈钢型不锈钢表表氨转化炉渗氮试验结果材料渗氮深度年。英寸。合金型不锈钢型不锈钢型不锈钢型不锈钢在和条件下氢气和氮气的环境中进行氮化研究结果表明,镍铁铬合金的氮化电阻随镍含量的增加而增加。尽管合金镍通常优选用于渗氮服务,但合金和镍对许多渗氮环境具有良好的耐受性。表比较了和合金与其他几种材料在氨转化器中进行的试验。样品在和下暴露于氢气和氮气的大气中。工作说明合金的加热和加工程序也适用于和合金。加热和酸洗所有要加热的材料必须清洁。和合金的特定退火程序取决于冷加工量材料的预期晶粒尺寸和横截面。严重冷加工材料的机械性能仅受到低于的温度的轻微影响。应力消除在约时开始,在后与厚度相当的时间内几乎完全消除。例如,板材产品应力消除的一般准则为每英寸厚度小时或温度下½小时,以较大者为准。

A summary of changes in weighing specifications contains new and updated information as shown in the table below. Environmental specifications This table provides the environmental specifications for the page with the declaration of conformity certificate and other certification details. According to and No. standards, the rated values of listed industrial control equipment used in hazardous areas, group enclosure types and ratings meet the requirements of typical touch screen analog resistance drive rating of 10000 times of pressing operation Likek analog resistance drive rating of million times of pressing operation pressure gram of pressing operation Likek keyboard function key applications. The electrical host port type input voltage is the terminal specification specification terminal inch and inch attribute inch. Touch in. Touch the keyboard, touch Add at the end of the catalog number, and order the terminal without logo and product identification, for example. The operator inputs the touch plus menu navigation button touch plus menu navigation button touch plus menu navigation button display type color thin-film transistor LCD display size, diagonal inches. Inch. Inch. The wide screen view is inches millimeters Display resolution aspect ratio::: color depth bit Color graphics color Typical brightness Backlight LED, non replaceable Life up to half brightness Hourly minute Backlight power consumption Typical touch screen analog resistance drive rating 10,000 times Press and operate the keyboard function keys, The maximum DC power consumption of the numeric keypad and navigation keys is the maximum. The maximum DC power consumption is the maximum. The line frequency power supply support and the power supply DC power supply terminal support safe ultra-low voltage and protective ultra-low voltage power supply, such as. Number support and DC power supply support or power supply mechanical weight is about mm × Inches Inches The cut size is approximately millimeters inches millimeters inches. Typical surge current line frequency power supply support and power DC power supply terminal support safe ultra-low voltage and protective ultra-low voltage power supply, such as. Numbering support and DC power supply support or power supply mechanical weight is about millimeters inches inches incision size is about millimeters inches millimeters inches terminal specifications product dimensions This table provides the product dimensions of the terminal platform. The inch touch and the combination keyboard with touch device shown in the figure are for illustration purposes. All other terminal sizes look similar. The model shown in the terminal size is inch terminal size terminal size input type height width inch total depth installation depth inch. Press the key to touch inch. Touch in. Key head inches. Touch in. Press the key to touch inch. Touch When installed in the pane, the front of the bezel is less than millimeters inches from the front of the bezel. In September, the terminal specification environment was used to create applications for the terminal platform. This environment includes the following main components, which you can create and design projects for specific terminals in the application and deploy in. Power supply and power junction box category. Number Description Quantity Guide rail power supply, output voltage, guide rail power supply, output power supply, guide rail power supply, AC power supply terminal, DC power supply terminal, year, month, terminal specifications Other resources These documents contain more information about related products. You can view or download it at://To order paper copies of the technical documents, please contact your local dealer or sales representative. Install the hardware category. No. Description Quantity Catalog No. Installation rod use * Cable rope length, clamp tensioner and eyebolt quantity Description Catalog No. Steel replacement spring Stainless steel replacement spring Product selection accessories * Note includes extension spring. September Technical specification for sports accessories Safety configuration and network module for interface cable application. Used to make your own cable Year Month Sport accessory specifications Low profile connector kit assemblies Low profile connector kits are designed for use with drives and modules. Use this table to determine the low profile connector kit for the feedback or connector. Size Low Profile Connector Kit Catalog Number Important Flywire compatible cables listed below require a connector kit to complete feedback and connection to the drive. Cat number indicates cable compatibility Thin connector kit male for motor feedback,. Use with any module or driver and compatible motors with incremental or high-resolution feedback. Battery catalog numbers required for use with high-resolution motors and bit encoders are not included. Low profile connector kit for motor feedback male, and male. Use with any module and compatible motors with incremental or high-resolution feedback. It does not include the battery catalog number required for use with the thin connector kit male provided by the customer,. The sum of at room temperature and is shown in the figure. Low cycle fatigue data of alloys. The excellent creep rupture strength of the alloy is shown in the parameter diagram in the figure. Alloy and alloy failure cycle total axial strain range, Fig. Alloy and low cycle fatigue strength under. Alloy and alloy failure cycle total axial strain range, Fig. Low cycle fatigue strength of the lower alloy and. Creep rate, Fig. Typical creep strength of alloy and. The representative breaking strength value of alloy&surface alloy, temperature, kips/square inch, fracture life, Fig. Alloy and parameter * *, in which temperature unit and fracture life unit hour chart. Alloy Boiler and Pressure Vessel Code The creep rupture strength of the alloy has been approved in accordance with the ASME Boiler and Pressure Vessel Code. Rules for the construction of power boilers are defined in Section, and rules for the construction of pressure vessels are defined in Section VII, Part and Part. The design stress values of the alloys under construction in Section and Section are listed in Section II, Materials, Part II, Performance Tables. The Code Case also covers the construction of Section. It is allowed to work at the following temperatures.. Produce and alloy products to optimize their advanced structure, which is the same as that in the performance table in Section II Materials Part.. Resistance to internal oxidation. Alloys&Cyclic exposure time, weight change, alloy alloys and graphs. Cyclic oxidation test results under. Table shows the results of carburizing test in the next hour, which will be compared with other alloys with high carburizing resistance. The atmosphere consists of methane and argon. Gas carburizing test results of alloy type stainless steel with hydrogen and methane alloy weight hours with hydrogen and methane alloy nitriding test results of alloy type stainless steel with ammonia converter nitriding test results of material nitriding depth years. Inch. Nitriding of alloy stainless steel stainless steel stainless steel stainless steel in hydrogen and nitrogen environment under and conditions shows that the nitriding resistance of Ni Fe Cr alloy increases with the increase of nickel content. Although alloy nickel is generally preferred for nitriding services, alloys and nickel have good resistance to many nitriding environments. Table compares the tests of and alloys in ammonia converter with those of other materials. The samples were exposed to hydrogen and nitrogen atmosphere at and. The heating and processing procedures for the job description alloys also apply to and alloys. Heating and pickling All materials to be heated must be clean. The specific annealing procedure for and alloys depends on the expected grain size and cross section of the cold worked material. The mechanical properties of severely cold worked materials are only slightly affected by temperatures below. The stress relief starts at about, and is almost completely relieved in the time corresponding to the thickness. For example, the general rule for stress relief of sheet products is hours per inch of thickness or at temperature ½ Hours, whichever is greater.