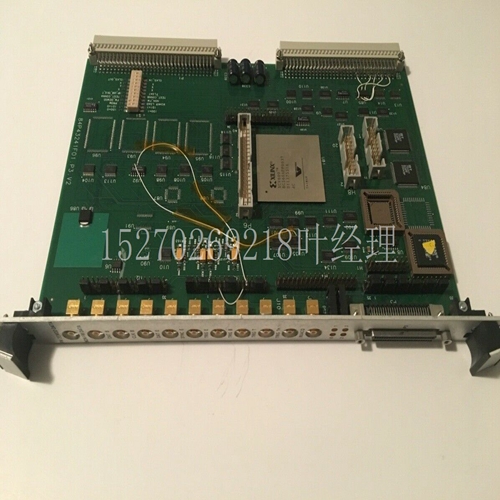

MVME172-353A备件库存

9 14 5.3环境和操作条件参考第4节中给出的规范和本节中的信息,确保不存在可能影响系统完整性的不利因素。5.3.1传感器垫乙烯基覆盖物的耐化学性–垫覆盖物的耐水性–优秀的乙醇–优秀的氯化钠–优秀的漂白–优秀的盐酸–优秀的硫酸–优秀的硝酸–优秀的乙酸–优秀的石油(汽油)–优秀的三氯乙烯–优秀的苯–较差的丙酮–较差一般来说,覆盖物具有优异的耐酸、耐碱和耐盐性。热酸和碱,以及浓酸和有机酸,对长时间接触有有害影响。该覆盖物对脂肪族溶剂具有较好的耐受性,对芳香族和氯化溶剂具有较好到较差的耐受性以及对酮和大多数酯的较差耐受性。注意:化学品的组合可能会产生不可预测的影响。在这种情况下,建议进行测试。若需要测试,供应商可提供小块乙烯基材料。5.3.2打滑/绊倒危险在大多数情况下,两种传感器垫模式都提供了防滑表面,但应保持无大量油脂、肥皂或凝胶沉积物。如果直肋侧位于最上方,建议肋骨穿过危险区域,以提高抓地力。5.3.3磨损和损坏垫子外表面可能因尖锐或重物的冲击而损坏。每次此类事件后,应检查垫子是否变形或穿孔,必要时应更换。垫子经过设计和测试,可以在任何一个地方承受一百万次操作。在使用中,不应超过任何单个位置的操作数。偶尔的重载(如3吨以下的卡车)不太可能损坏垫子,但不应在通过路线的交通中使用。5.3.4爆炸性环境该系统不适用于爆炸性环境。15 5.3.5 E.M.C.垫子系统符合欧洲EMC指令的要求。确保了在工业环境中可能出现的干扰条件下的正常操作,并已通过测试和认证。

注:当存在异常高水平的电磁干扰时,可能需要采取特殊措施,例如靠近焊接或感应加热设备或靠近无线电发射机/收发器。5.3.6地板传感器垫的地板或安装表面必须平整、光滑且坚硬,即在预计的最大载荷下不会出现明显变形。起伏、凸起、大间隙或其他不规则现象将增加传感器垫的灵敏度,并可能导致间歇性意外关闭(有害跳闸)。图10垫子的地板状况。可接受小而规则的突起,如棋盘图案。脱脂混凝土地板是理想的。如果有任何疑问,请联系供应商。5.3.7控制单元安装(参考图8第4节)控制单元不得安装在检测区域内。如果手动复位或常规指示器观察需要接近控制单元,则应将其安装在保护区外的可接近位置,以便能很好地观察危险和保护区。复位执行机构应位于保护区外,且位置应确保危险和保护区清晰可见。在其他情况下,考虑到测试和维护的访问要求,控制单元可以安装在保护区外任何方便的地方。440F-C4000D控制单元应安装在防护等级至少为IP 54的外壳内(符合EN 60529)。注意:控制装置不适合直接暴露于高压清洗。5.4垫子定位5.4.1用作组合跳闸和存在感测装置垫子边缘的定位计算为与危险区的水平距离。将危险区域定义为一个体积,考虑到机器的所有可能模式和工件尺寸的所有变化。

9 14 5.3 Environmental and operating conditions Refer to the specifications given in Section 4 and the information in this section to ensure that there are no adverse factors that may affect system integrity. 5.3.1 Chemical resistance of sensor pad vinyl cover – water resistance of pad cover – excellent ethanol – excellent sodium chloride – excellent bleaching – excellent hydrochloric acid – excellent sulfuric acid – excellent nitric acid – excellent acetic acid – excellent petroleum (gasoline) – excellent trichloroethylene – excellent benzene – poor acetone – poor Generally speaking, the cover has excellent acid, alkali and salt resistance. Hot acid and alkali, as well as concentrated acid and organic acid, have harmful effects on long-term contact. The cover has good tolerance to aliphatic solvents, good to poor tolerance to aromatic and chlorinated solvents, and poor tolerance to ketones and most esters. Note: The combination of chemicals may have unpredictable effects. In this case, testing is recommended. If testing is required, the supplier can provide small pieces of vinyl material. 5.3.2 Slipping/tripping hazard In most cases, both sensor pad modes provide a non slip surface, but should be kept free of large amounts of grease, soap or gel deposits. If the straight rib side is at the top, it is recommended that the rib pass through the danger area to improve the grip. 5.3.3 Wear and damage The outer surface of the mat may be damaged by sharp or heavy impact. After each such event, the mat shall be checked for deformation or perforation and replaced if necessary. The cushion is designed and tested to withstand a million operations anywhere. In use, the operands of any single position shall not be exceeded. Occasional heavy loads (such as trucks under 3 tons) are unlikely to damage the mat, but should not be used in traffic passing the route. 5.3.4 Explosive environment The system is not applicable to explosive environment. 15 5.3.5 The E.M.C. mat subsystem complies with the requirements of the European EMC Directive. It ensures normal operation under possible interference conditions in industrial environment, and has passed the test and certification.

Note: When there is an abnormally high level of electromagnetic interference, special measures may be required, such as close to welding or induction heating equipment or close to radio transmitters/transceivers. 5.3.6 The floor or installation surface of the floor sensor pad must be flat, smooth and hard, that is, no obvious deformation will occur under the expected maximum load. Fluctuations, bulges, large gaps, or other irregularities will increase the sensitivity of the sensor pads and may cause intermittent accidental shutdowns (harmful trips). Fig. 10 Floor condition of mat. Small and regular protrusions, such as chessboard patterns, are acceptable. Degreasing concrete flooring is ideal. If you have any questions, please contact the supplier. 5.3.7 Installation of control unit (refer to Section 4 of Figure 8) The control unit shall not be installed in the detection area. If manual reset or conventional indicator observation requires access to the control unit, it should be installed in an accessible position outside the protected area so that the danger and protected area can be observed well. The reset actuator shall be located outside the protected area, and the location shall ensure that the danger and the protected area are clearly visible. In other cases, considering the access requirements for testing and maintenance, the control unit can be installed at any convenient place outside the protected area. The 440F-C4000D control unit shall be installed in an enclosure with a degree of protection of at least IP 54 (in accordance with EN 60529). Note: The control device is not suitable for direct exposure to high-pressure cleaning. 5.4 Cushion positioning 5.4.1 The positioning of the edge of the cushion used for combined tripping and presence sensing devices is calculated as the horizontal distance from the hazardous area. The hazardous area is defined as a volume, taking into account all possible modes of the machine and all changes in the size of the workpiece.