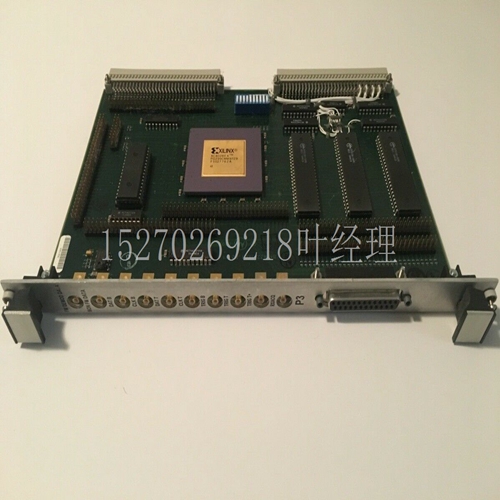

MVME172-453A模块备件

6.安全输出:这些是用于连接到机器安全电路的无电压端子,即,它们与机器接触器控制电路(最大额定值250V 4A)串联连接。应使用额定值适当的保险丝对其进行外部保护。对于一个接触器,使用连接端子14和23的端子13和24。对于具有两个独立控制电路(即双通道系统)的两个接触器,使用13和14连接到一个接触器控制电路,使用23和24连接到另一个接触器。参见图。14/15和16/17,用于与机器控制电路的典型接口示例。注意:安全输出应通过硬接线直接连接到机器主控制元件(接触器)。它们不得通过任何元件连接,例如普通继电器、PLC等,这些元件未适当指定用于安全相关功能。7.接触器监控:控制单元配有这些连接的端子。当链路被移除时,它们可以连接到机器接触器上的正向导向N/C辅助触点,以监控双通道控制系统中的接触器。如果一个接触器在其控制线圈断电时未能隔离电源,则在故障排除之前,垫控制单元将不允许另一个接触器通电。8.远程复位:N/O-这些端子用于连接远程复位按钮。

这必须是一个N/O瞬时按钮装置,其位置应能提供检测区域的全貌。仅限440F-C4000P、440F-C4000 S、440F-C28013。如果从控制单元上看不到危险区域的全貌,请断开接线盒上控制单元盖上的复位开关的电线,以禁用控制单元的复位功能。9.远程复位指示:如果与发光的按钮远程复位开关一起使用,将显示何时需要复位垫子系统。这些端子用于连接灯泡(28V)。32 MAT 1 MAT 2 MAT 3 MAT 4 MAT 5 MAT 6 MAT 7短接插头MAT 8 10.手动复位/自动复位:M/A开关。将M/A开关设置为所需设置。M=手动复位模式A=自动复位模式。11.根据建立的电压和模式设置标记并签署标签。12.标记为1至8的八个六通接头。这些接头是控制单元的垫连接,并连接到单元外部的外部快速连接插头。13.重新检查接线连接,包括机器控制系统接线的连接或修改。更换盖。将盖固定在相关单元上。断开机器原动机与最终接触器的连接,使机器无法移动。6.3检查机械安装1.检查传感器垫、周边装饰件和联合装饰件是否完好无损,是否正确定位和固定。检查是否达到了设计的安全距离。2.检查除了通过垫子之外,是否无法进入危险区域,并且任何固定防护装置等是否根据设计进行了定位,并且是否安全。3.检查危险区和垫子系统之间是否有人。4.检查当前或可预见的环境条件是否符合设计阶段考虑的环境条件。

6. Safe output: These are the voltage free terminals used to connect to the machine safety circuit, that is, they are connected in series with the machine contactor control circuit (maximum rated value 250V 4A). They shall be externally protected by suitably rated fuses. For a contactor, use terminals 13 and 24 that connect terminals 14 and 23. For two contactors with two independent control circuits (i.e. dual channel system), use 13 and 14 to connect to one contactor control circuit and 23 and 24 to connect to the other contactor. See Fig. 14/15 and 16/17 for typical interface examples with machine control circuits. Note: The safety output should be directly connected to the main control element (contactor) of the machine through hard wiring. They shall not be connected by any element, such as common relays, PLC, etc., which are not properly designated for safety related functions. 7. Contactor monitoring: the control unit is equipped with these connected terminals. When the links are removed, they can be connected to the positive pilot N/C auxiliary contacts on the machine contactors to monitor the contactors in the dual channel control system. If a contactor fails to isolate power when its control coil is powered off, the pad control unit will not allow another contactor to be powered on before troubleshooting. 8. Remote reset: N/O - These terminals are used to connect the remote reset button.

This must be a N/O instantaneous button device, whose position should provide a full view of the detection area. Only 440F-C4000P, 440F-C4000 S, 440F-C28013. If you cannot see the full view of the hazardous area from the control unit, disconnect the wire of the reset switch on the control unit cover on the junction box to disable the reset function of the control unit. 9. Remote reset indication: if it is used together with the illuminated button remote reset switch, it will display when the mat subsystem needs to be reset. These terminals are used to connect bulbs (28V). 32 MAT 1 MAT 2 MAT 3 MAT 4 MAT 5 MAT 6 MAT 7 Short circuit plug MAT 8 10. Manual reset/automatic reset: M/A switch. Set the M/A switch to the desired setting. M=manual reset mode A=automatic reset mode. 11. Set the mark and sign the label according to the established voltage and mode. 12. Eight six way connectors marked 1 to 8. These connectors are pad connections for the control unit and are connected to the external quick connect plug outside the unit. 13. Recheck the wiring connection, including the connection or modification of the machine control system wiring. Replace the cover. Secure the cover on the relevant unit. Disconnect the machine prime mover from the final contactor so that the machine cannot move. 6.3 Check the mechanical installation 1. Check whether the sensor pad, peripheral trim and joint trim are intact and correctly positioned and fixed. Check whether the designed safety distance is reached. 2. Check whether it is impossible to enter the dangerous area except through the mat, and whether any fixed protective devices are positioned according to the design and safe. 3. Check if there is anyone between the hazardous area and the mat subsystem. 4. Check whether the current or foreseeable environmental conditions meet the environmental conditions considered at the design stage.