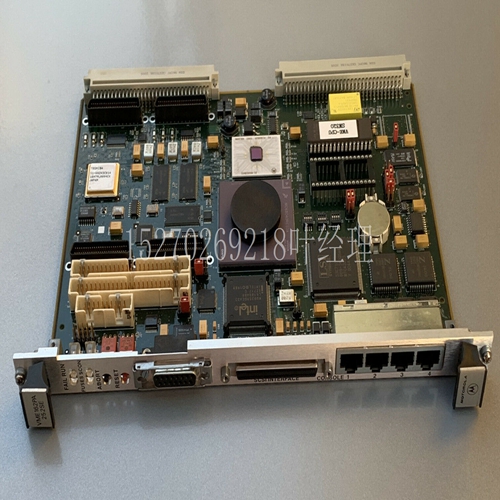

MVME187-001B控制卡件

d对于电动和手动齿轮驱动截止阀,包括止回型截止阀,高压关闭试验应在用于确定操作器尺寸的设计压差的110%下进行。e所有指定为双截断和排放阀的阀门都需要进行高压关闭试验。版权所有美国石油学会由IHS提供,经API许可证持有人=阿尔伯塔大学/5966844001,用户=sam,albert未经IHS许可,不得复制或联网,不得转售,2013年6月28日16:13:35 MDT 6 API STANDARD 598 5.4高压关闭试验几种阀门类型需要进行高压关闭试验,如表1和表2所示。对于根据表1和表2,高压关闭试验是可选的阀门类型,阀门仍然需要能够通过试验(作为阀门关闭结构设计的试验)。当询价请购单或买方要求时,应提供确认阀门设计能力通过高压关闭试验的试验结果。试验压力计算见表4脚注b和c。5.5高压气动壳体试验当采购订单规定时,应进行高压气动外壳试验。该试验应在壳体试验后进行,并采用适当的安全预防措施。气动外壳试验压力应为38°C(100°F)或采购订单中规定的最大允许压力的110%。

不允许出现可见泄漏。5.6试验流体5.6.1对于外壳、高压后座和高压关闭试验,试验流体应为空气、惰性气体、煤油、水或粘度不高于水的非腐蚀性液体。除非请购单中另有规定,否则测试流体温度应在5°C(41°F)至50°C(122°F)的范围内。5.6.2对于低压关闭和低压后座试验,试验流体应为空气或惰性气体。5.6.3当使用空气或气体进行关闭、外壳或后座试验时,阀门制造商应能够证明泄漏检测方法的充分性。5.6.4用于任何试验的水可能含有水溶性油或防锈剂。如果买方有规定,水中应包含润湿剂。对于奥氏体不锈钢阀门的测试,应使用氯化物含量不超过100 ppm的水。阀门制造商应能够记录氯化物含量。5.7试验压力5.7.1外壳试验压力应如表3所示。5.7.2其他试验压力应按表4所示。5.8试验持续时间对于每种类型的试验,所需的试验压力应至少保持表5所规定的最短时间。5.9试验泄漏5.9.1外壳、阀杆密封和后座5.9.1.1对于外壳试验,不允许通过压力边界壁和任何固定主体接头目视检测到泄漏。5.9.1.2对于后座试验,不允许目视检测泄漏。5.9.1.3对于带有可调阀杆密封件的阀门,外壳试验期间阀杆密封件泄漏不应成为拒收原因。

D For electric and manual gear driven globe valves, including check type globe valves, the high pressure closure test shall be performed at 110% of the design differential pressure used to size the operator. E All valves designated as double block and drain valves shall be subject to high-pressure closing test. Copyright American Petroleum Institute is provided by IHS. API licensees=University of Alberta/5966844001, users=sam, albert are not allowed to copy or network without permission of IHS, and cannot be resold. On June 28, 2013, 16:13:35 MDT 6 API STANDARD 598 5.4 High pressure closing test Several valve types need to be subject to high pressure closing test, as shown in Table 1 and Table 2. According to Table 1 and Table 2, the high-pressure closing test is an optional valve type, and the valve still needs to be able to pass the test (as the test of valve closing structure design). When requested by the inquiry requisition or the Buyer, the test results confirming that the valve design capacity has passed the high pressure closing test shall be provided. See footnotes b and c of Table 4 for the calculation of test pressure. 5.5 High pressure pneumatic shell test When specified in the purchase order, the high pressure pneumatic shell test shall be carried out. The test shall be carried out after the shell test and appropriate safety precautions shall be taken. The test pressure of the pneumatic enclosure shall be 38 ° C (100 ° F) or 110% of the maximum allowable pressure specified in the purchase order.

No visible leakage is allowed. 5.6 Test fluid 5.6.1 For shell, high-pressure backseat and high-pressure closing test, the test fluid shall be air, inert gas, kerosene, water or non corrosive liquid with viscosity not higher than water. Unless otherwise specified in the requisition, the test fluid temperature shall be within the range of 5 ° C (41 ° F) to 50 ° C (122 ° F). 5.6.2 For low pressure shutdown and low pressure backseat tests, the test fluid shall be air or inert gas. 5.6.3 The valve manufacturer shall be able to demonstrate the adequacy of the leak detection method when air or gas is used for closure, enclosure or backseat tests. 5.6.4 The water used for any test may contain water-soluble oil or rust inhibitor. If specified by the purchaser, the water shall contain a wetting agent. For testing austenitic stainless steel valves, water with chloride content not exceeding 100 ppm shall be used. The valve manufacturer shall be able to record the chloride content. 5.7 Test pressure 5.7.1 The shell test pressure shall be as shown in Table 3. 5.7.2 Other test pressures shall be as shown in Table 4. 5.8 Test duration For each type of test, the required test pressure shall be kept at least for the shortest time specified in Table 5. 5.9 Test leakage 5.9.1 Shell, valve stem seal and backseat 5.9.1.1 For shell test, it is not allowed to visually detect leakage through the pressure boundary wall and any fixed body joint. 5.9.1.2 For the backseat test, it is not allowed to visually detect the leakage. 5.9.1.3 For valves with adjustable valve stem seals, leakage of valve stem seals during shell test shall not be the reason for rejection.