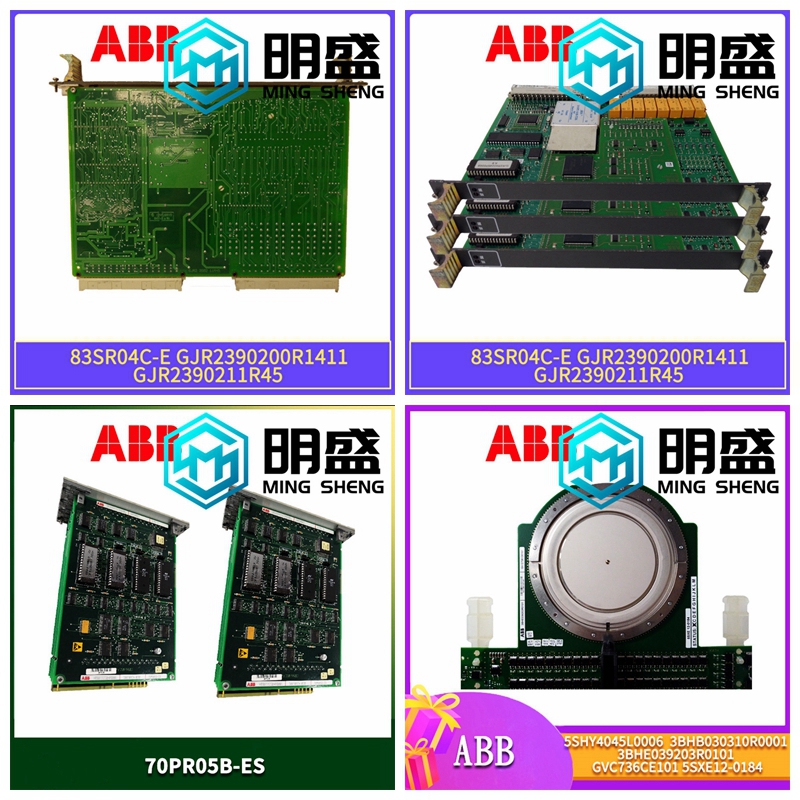

MVME2431-1工控模块卡件

在可持续性框架内,对现有结构进行FRP改造可能会带来好处,有助于提高改造结构的寿命和安全性。因此,FRP加固可被视为加固和修复现有结构的可持续设计的可行方法。Napolano等人(2015)、Moliner Santisteve等人(2013)、Zhang等人(2012)和Das(2011)列举了通过LCA调查评估的FRP的环境优势。1.2范围本文件为外部加固混凝土结构的FRP系统的选择、设计和安装提供了指导。介绍了用作外部加固的FRP系统的材料性能、设计、安装、质量控制和维护信息。该信息可用于选择FRP系统,以增加钢筋混凝土梁的强度、刚度或两者,或柱的延性和其他应用。本指南的基础是大量研究。这项研究始于20世纪80年代,包括FRP加固系统的分析研究、实验工作和现场监测应用。根据现有研究,本文概述的设计程序被认为是保守的。FRP材料的耐久性和长期性能一直是许多研究的主题;然而,这项研究仍在进行中。

本指南中的设计指南通过提供各种环境的降低系数,说明了环境退化和长期耐久性。本文件中指出的应力限制也解决了长期疲劳和蠕变问题。这些因素和限制被认为是保守的。然而,随着更多的研究变得可用,这些因素可能会被修改,具体的环境条件和荷载条件将得到更好的定义。此外,环境条件和负载条件的耦合效应需要进一步研究。在FRP系统同时受到极端环境和应力条件影响的应用中,应小心谨慎。与FRP系统的长期耐久性相关的因素也可能影响用于设计的材料的拉伸弹性模量。关于FRP系统与基材的结合的许多问题仍然是大量研究的焦点。对于弯曲和剪切加固,有许多不同的脱粘破坏模式可以控制FRP加固构件的强度。虽然研究人员已经确定了大多数脱粘模式,但仍需要更准确的方法来预测脱粘。在整个设计过程中,对FRP材料中获得的应变(以及由此获得的应力)施加了重大限制,以保守地解释脱粘失效模式。这些设计程序的未来发展应包括更全面的脱粘预测方法。本文件为FRP系统的正确详细设计和安装提供了指导,以防止多种类型的脱粘失效模式。

Within the framework of sustainability, FRP retrofitting of existing structures may bring benefits and help improve the life and safety of retrofitted structures. Therefore, FRP strengthening can be considered as a feasible method for sustainable design of strengthening and repairing existing structures. Napolano et al. (2015), Moliner Santisteve et al. (2013), Zhang et al. (2012) and Das (2011) listed the environmental advantages of FRP assessed through LCA survey. 1.2 Scope This document provides guidance for the selection, design and installation of FRP systems for externally reinforced concrete structures. The material properties, design, installation, quality control and maintenance information of FRP system used for external reinforcement are introduced. This information can be used to select FRP systems to increase the strength, stiffness, or both of reinforced concrete beams, or the ductility of columns and other applications. This guide is based on extensive research. This research started in the 1980s, including the analysis and research, experimental work and field monitoring application of FRP strengthening system. Based on existing research, the design procedures outlined in this paper are considered conservative. The durability and long-term performance of FRP materials have been the subject of many studies; However, the study is still in progress.

The design guidelines in this guide describe environmental degradation and long-term durability by providing reduction factors for various environments. The stress limits indicated in this document also address long-term fatigue and creep problems. These factors and limitations are considered conservative. However, as more research becomes available, these factors may be modified and specific environmental and loading conditions will be better defined. In addition, the coupling effect of environmental conditions and load conditions needs further study. Care should be taken in applications where FRP systems are subject to both extreme environmental and stress conditions. Factors related to the long-term durability of the FRP system may also affect the tensile modulus of elasticity of the materials used for design. Many problems about the combination of FRP system and substrate are still the focus of a lot of research. For flexural and shear strengthening, there are many different debonding failure modes that can control the strength of FRP strengthened members. Although researchers have identified most debonding modes, more accurate methods are needed to predict debonding. Throughout the design process, significant limitations were placed on the strain (and hence the stress) obtained in the FRP material to conservatively explain the debonding failure mode. The future development of these design programs should include more comprehensive debonding prediction methods. This document provides guidance for the proper detailed design and installation of FRP systems to prevent multiple types of debonding failure modes.