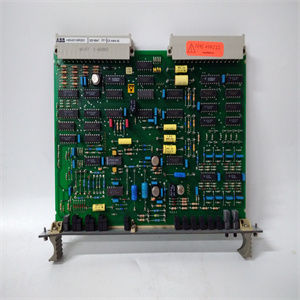

PFTL201DE 100.0KN工控模块系统备件

出版物95302194/EO:0240发行号:8 23 440F MatGuard™ Mat Manager用户手册第5节-安装设计图21显示了440F-C28025的示例连接图。电路条件如下:电源开启;传感器垫上不存在,常开安全输出关闭,负载断电。控制单元配置为自动/手动复位。按下并松开启动按钮,为负载通电。踩在任何垫子上都会导致安全输出打开并切断负载的电源。离开垫子后,必须按下并松开启动按钮,以重新给负载通电。图21图22显示了440F-C28026的示例连接图。电路条件如下:电源开启;传感器垫上不存在,常开安全输出打开,负载断电。控制单元配置为监控手动复位。按下并释放复位按钮,为负载通电。踩在任何垫子上都会导致安全输出打开并切断负载的电源。离开垫子后,必须按下并释放重置按钮,以重新给负载通电。+24V DC DC接地PE接地保险丝启动K1 Aux K2 Aux Stop 1 23 4 2 5 6 7 8 1 6 440F-C28025 Mat Manager控制单元K1 K1 K2 K2 3 758最多8个传感器垫电机L1 L2 L3重置M A 440F MatGuard™ Mat Manager用户手册第5节-安装设计24罗克韦尔自动化出版物95302194/EO:0240第8期)图22安全相关控制系统设计完成后,确保5.4.1中假设的响应时间保持有效。如果值发生变化,则需要重复安全距离计算。接下来考虑重置选项。在正常条件和故障条件下,应仔细考虑所选重置方案的后果,以防意外启动等造成的危险。Allen-Bradley Guardmaster系统两种模式的时序图如图23所示。图23可通过控制单元内的选择开关配置两种重置操作模式:手动重置和自动重置。手动复位模式在手动复位模式中,只有在移除驱动力并复位后,输出“ON”信号才能恢复。手动复位通过按下和释放远程安装的瞬时复位按钮或通过机器安全相关控制系统内的无电压触点实现。在通电或断电后以及随后恢复电源后,输出将“关闭”,直到收到复位信号,即使垫子未启动。Allen-Bradley Guardmaster控制单元的安全输出35 ms响应时间重置驱动力控制单元安全输出功率

.Publication 95302194/EO:0240 Issue No: 8 23 440F MatGuard™ Mat Manager User Manual Section 5 - Installation Design Figure 21 shows an example connection diagram for the 440F-C28025. The circuit conditions are as follows: supply power is ON; no presence on the sensor mats, the normally open safety outputs are closed and the loads are de-energized. The control unit is configured for automatic/manual reset. Press and release the start button to energize the loads. Stepping on any of the mats will cause the safety outputs to open and remove power to the loads. After stepping off the mat, the start button must be pressed and released to re-energize the loads. Figure 21 Figure 22 shows an example connection diagram for the 440F-C28026. The circuit conditions are as follows: supply power is ON; no presence on the sensor mats, the normally open safety outputs are open and the loads are de-energized. The control unit is configured for monitored manual reset. Press and release the reset button to energize the loads. Stepping on any of the mats will cause the safety outputs to open and remove power to the loads. After stepping off the mat, the reset button must be pressed and released to re-energize the loads. + 24V DC DC Ground PE Ground Fuse Start K1 Aux K2 Aux Stop 1 23 4 2 5 6 7 8 1 6 440F-C28025 Mat Manager Control Unit K1 K1 K2 K2 3 758 Up to 8 Sensor Mats Motor L1 L2 L3 Reset M A 440F MatGuard™ Mat Manager User Manual Section 5 - Installation Design 24 Rockwell Automation Publication 95302194/EO:0240 Issue No: 8) Figure 22 After completion of the design of the safety related control system ensure that the response time assumed at 5.4.1 remains valid. If the value changes, it will be necessary to repeat the safety distance calculations. Next consider the options for reset. The consequences of the reset scheme selected should be carefully considered for hazards caused by unexpected start up etc., both under normal conditions and under fault conditions. Timing diagrams are given in Figure 23 for both modes of the Allen-Bradley Guardmaster system. Figure 23 Two Reset operating modes are configurable via selection switch inside the Control Unit: Manual Reset and Auto Reset. Manual Reset Mode In manual reset mode the output “ON” signal can only be restored after the actuating force has been removed and after a reset. The manual reset is achieved by pushing and releasing a remotely mounted momentary reset button or by voltage free contacts within the machine safety related control system. At power-on or following the loss and subsequent restoration of power, the outputs will be “OFF” until a reset signal is received even if the mat is not actuated. The safety outputs of Allen-Bradley Guardmaster control unit 35 ms Response Time Reset Actuating Force Control Unit Safety Outputs Power