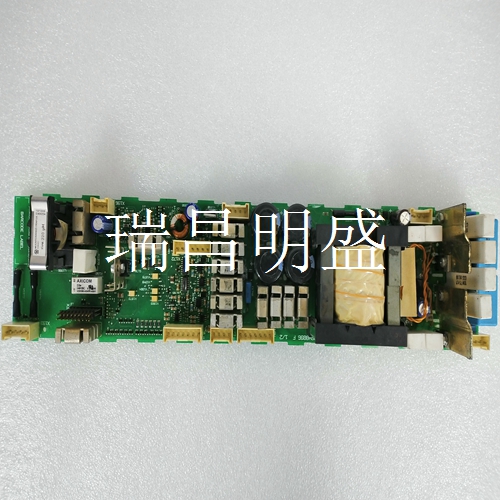

RCU500处理器模块

安装和调试应由系统设计师监督。需要一名熟悉工业布线实践的机械技术人员和一名电工进行安装。调试应由在安全安装方面有经验的训练有素的电气技术人员进行。需要以下专用工具:预绝缘对接接头的压接工具图21连接器(如Raychem AD-1522-T)图22热收缩用带反射器附件的热风枪(如Rayhem HL1802E)6.1 MAT INSTALLATION隔离并锁定机器电源。检查地板是否平整、光滑、干净、无碎屑,以及任何埋地管道或其他布线是否正确到位。拆开垫子,小心保持平整,不要拉扯电线。将垫子放置在地板上的计划位置,连接线位于检测区域的外围。根据图23将垫段连接在一起。图23注意:垫线具有黑色外层。两个具有黑色内护套,两个具有白色内护套(位置见图23)。控制单元1 2 3 4 26处的传感器垫白-黑-白-白-黑,黑-黑-黑,白-白,黑-白,白-黑端子留有足够的线尾长度,以便在更换垫的情况下重新制作连接,但确保互连电线能够轻松地安装在边缘装饰件下方,而不会被挤压。使用下图24所示的对接连接器连接电线。如果垫线需要延伸,例如前垫到后垫的连接和控制单元连接,则使用额外的一对对接连接器和一段双导线(参见布线规范-第6.2节)。图24组合修剪固定安装中使用的所有活动组合修剪部分必须斜接至45°。这有助于安装,并有助于保持传感区域的整体灵敏度。图24a周边饰板固定如果控制单元的接线未埋置,则在电线入口和出口位置切割周边饰板,并切割饰板坡度以适合所选导管系统。小心完全开槽,以便周边装饰件的任何弯曲都不会夹住电线。确保没有可能损坏导线的锐边或毛刺。图25进入电缆槽(周边饰板底部)的垫线建议切口的饰板固定件详图440F-T3013挠性导管入口建议切口的铝制内角周边饰板(与440F-T3510、440F-T3310和440F-T3210一起使用)440F-T3012铝制外角周边饰条(与440F-13510、440 F-T3310及440F-T3211一起使用)应力释放夹具挠性导管切口槽此处,在锋利的边缘上使用边缘护环剥下8mm的电线并插入压接筒。使用压接工具上正确的空腔尺寸压接。使用带导流板的加热枪加热压接接头,直到管道收缩,粘合剂收缩并流动。

Installation and commissioning shall be supervised by the system designer. A mechanical technician familiar with industrial wiring practice and an electrician are required for installation. The commissioning shall be carried out by trained electrical technicians with experience in safe installation. The following special tools are required: crimping tool for pre insulated butt joint Figure 21 Connector (such as Raychem AD-1522-T) Figure 22 Heat shrinkable hot air gun with reflector accessories (such as Raychem HL1802E) 6.1 MAT INSTALLATION Isolate and lock the machine power supply. Check that the floor is flat, smooth, clean and free of debris and that any buried piping or other wiring is in place. Remove the mat and be careful to keep it flat. Do not pull the wire. Place the mat at the planned position on the floor, and the connecting line is located at the periphery of the detection area. Connect the cushion sections together according to Figure 23. Fig. 23 Note: The padding line has a black outer layer. Two have black inner sheaths and two have white inner sheaths (see Figure 23 for location). The sensor pad white black white black, black black black, white white, black white, black white, white black terminals at the control unit 1 2 3 4 26 have enough tail length to make a connection again when the pad is replaced, but ensure that the interconnection wire can be easily installed under the edge trim without being squeezed. Use the butt connector shown in Figure 24 below to connect the wires. If the pad wire needs to be extended, such as the connection from the front pad to the rear pad and the control unit connection, use an additional pair of butt connectors and a section of double wires (see Wiring Specifications - Section 6.2). Fig. 24 All the movable combined trim parts used in the combined trim fixing installation must be mitered to 45 °. This facilitates installation and helps maintain the overall sensitivity of the sensing area. Figure 24a Fixing the peripheral trim panel If the wiring of the control unit is not embedded, cut the peripheral trim panel at the wire inlet and outlet, and cut the trim panel slope to fit the selected conduit system. Be careful to fully slot so that any bending of the surrounding trim will not trap the wire. Make sure there are no sharp edges or burrs that could damage the wires. Figure 25 Detail of trim panel fastener with recommended notch for pad wire entering cable tray (bottom of peripheral trim panel) 440F-T3013 Aluminum inner corner peripheral trim panel with recommended notch for flexible conduit entrance (used with 440F-T3510, 440F-T3310 and 440F-T3210) 440F-T3012 Aluminum outer corner peripheral trim strip (used with 440F-13510, 440 F-T3310 and 440F-T3211) Stress release fixture Flexible conduit notch here, Peel off 8mm wires on sharp edges with edge protectors and insert the crimping cartridge. Crimp with the correct cavity size on the crimping tool. Use a heat gun with a deflector to heat the crimp joint until the pipe shrinks and the adhesive shrinks and flows.