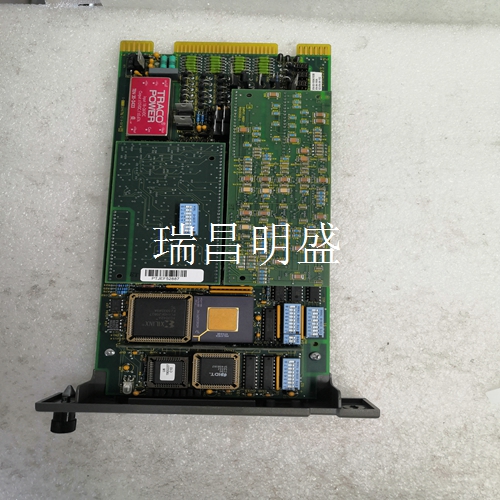

DSBB110A 57330001-Y 工控模块控制器

安装 说明适用于典型的安装布置

如果符合第C.4节“安装要求”中的要求,则允许进行变更。1.清洁基础和其他安装表面。2.将下转接板安装到称重传感器上。用扭矩扳手将螺钉(包括在交付中)拧紧至24 Nm(18 ft-lb)。3.将称重传感器和下转接板安装到基础上,但不要完全拧紧螺钉。4.将上转接板安装到称重传感器上。用扭矩扳手将螺钉(包括在交付中)拧紧至24 Nm(18 ft-lb)。5.将轴承箱和辊安装到上转接板上,但不要完全拧紧螺钉。注意:当将轴承或其他相邻部件安装到转接板上时,螺钉不得伸入测压元件。施加的力过大会损坏称重传感器。6.根据安装要求调整称重传感器。拧紧地脚螺钉。7.根据安装要求调整辊。拧紧上部适配器板中的螺钉。

设计程序

包括以下章节:•基本应用注意事项•设计称重传感器安装(分步指南)•安装要求•力和缠绕增益计算–水平安装–倾斜安装–单侧测量•安装称重传感器•技术数据•图纸–电缆图–尺寸图D.2基本应用注意事项每个应用程序都有其需要考虑的单独需求;尽管一些基本考虑往往会重复。•涉及哪种类型的工艺(造纸、转化等)?环境是否苛刻(温度、化学品等)?•张力测量的目的是什么;指示还是闭环控制?是否有任何具体的精度要求?•机器的设计是什么样的?是否有可能修改设计,以便安装最合适的称重传感器,或者机器设计是否固定?•作用在辊上的力是什么样的(大小和方向)?它们可以通过重新设计来改变吗?如果彻底解决了这些问题,安装很有可能成功。然而,在设计称重传感器装置时,需要测量精度的程度决定了要求。

Installation instructions apply to typical installation arrangements

Changes are allowed if the requirements in Section C.4 "Installation Requirements" are met. 1. Clean the foundation and other installation surfaces. 2. Install the lower adapter plate onto the load cell. Tighten the screws (included in delivery) with a torque wrench to 24 Nm (18 ft lb). 3. Install the load cell and lower adapter plate onto the foundation, but do not fully tighten the screws. 4. Install the upper adapter plate onto the load cell. Tighten the screws (included in delivery) with a torque wrench to 24 Nm (18 ft lb). 5. Install the bearing housing and roll onto the upper adapter plate, but do not fully tighten the screws. Note: When installing the bearing or other adjacent components on the adapter plate, the screw shall not protrude into the load cell. Excessive force will damage the load cell. 6. Adjust the load cell according to the installation requirements. Tighten the anchor screws. 7. Adjust the roll according to the installation requirements. Tighten the screws in the upper adapter plate.

Design procedure

The following sections are included: • Basic application considerations • Design load cell installation (step-by-step guide) • Installation requirements • Force and winding gain calculation – Horizontal installation – Inclined installation – One side measurement • Installing load cells • Technical data • Drawings – Cable diagram – Dimensional drawing D 2 Basic application considerations Each application has its own needs to consider; Although some basic considerations are often repeated. • What type of process is involved (papermaking, conversion, etc.)? Is the environment harsh (temperature, chemicals, etc.)? • What is the purpose of tension measurement; Indication or closed-loop control? Are there any specific accuracy requirements? • What is the design of the machine? Is it possible to modify the design to install the most suitable load cell, or is the machine design fixed? • What is the force acting on the roll (magnitude and direction)? Can they be changed by redesign? If these problems are completely solved, the installation is likely to succeed. However, when designing a load cell device, the degree of measurement accuracy required determines the requirements.