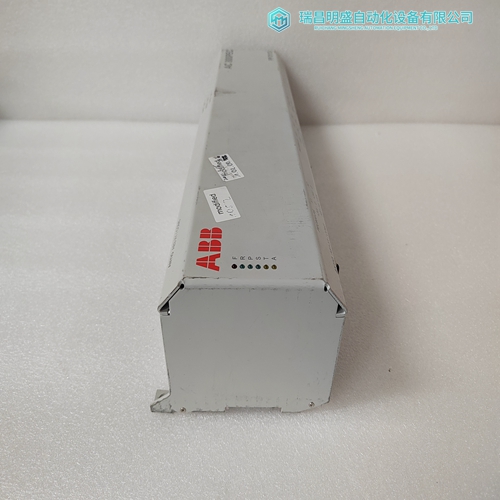

产品细节介绍

PPD113B03-26-100100控制器

机械堵塞

如果该过程导致电机容易发生机械堵塞,请相应地设置机械堵塞跳闸和警报。在里面大多数情况下,过载跳闸将在机械跳闸之前激活,但是,如果选择高过载曲线,机械堵塞水平和时间延迟变得更为关键。然后应将设置设置为低于过载曲线但高于电机的任何正常过载条件。机械卡住元件的主要用途是保护因设备堵塞或损坏而驱动的设备。

暗流如果特定应用需要检测负载损失,则根据以下电流设置欠流元件将指示负载损失。例如,可以为泵应用程序编程,以检测管道中的流体损失。不平衡报警和跳闸通过检查电机应用和电机设计来确定不平衡设置。在这种情况下,电机受保护的是往复式压缩机,在这种情况下,不平衡将是一种正常的运行状态,因此该设置应为设置为高。不平衡报警的设置为20%,延时为10秒是合适的,可以设置跳闸至25%,延迟10秒接地故障遗憾的是,没有足够的信息来确定接地故障设置。

这些设置取决于以下内容信息:

1.接地故障电流可用。

2.系统接地-高电阻接地、牢固接地等。

3.使用接地故障CT。

4.接地故障连接-零序或剩余连接。

加速跳闸

该设定值应设置为高于最大启动时间,以避免在电压较低或用于启动期间的不同负载。如果使用降压起动,则设置为8秒是合适的,如果是直接起动如果使用跨线启动,则可以使用5秒的设置。

启动禁止在五次成功启动后,应始终启用此功能,以在启动时保护电机热的369学习开始时使用的热容量。如果电机是热的,因此具有一定的热容量如果可用热容量小于启动所需的热容量,369将不允许启动。更多信息有关禁止启动的信息,请参阅第7.6.6节中的应用说明。

开始时间/小时启动次数/小时可根据数据表设置为冷启动次数。对于本例,starts/hour将设置为3。

启动间隔时间

在某些情况下,电机制造商将指定电机启动之间的时间间隔。在本例中,此信息不是因此此功能可以“关闭”。但是,如果给出了信息,则电机数据表上提供的时间应进行编程。

定子RTD

RTD跳闸水平应设置为或低于绝缘的最高温度额定值。该示例具有F级绝缘,其额定温度为155°C,因此定子RTD跳闸水平应设置为140°C至155°C。RTD警报级别应设置为一个级别,以警告电机温度正在上升。为了这个例如,120°C或130°C是合适的。

轴承RTD

轴承RTD报警和跳闸设置将通过评估轴承的温度规格来确定

Mechanical Jam

If the process causes the motor to be prone to mechanical jams, set the Mechanical Jam Trip and Alarm accordingly. In most cases, the overload trip will become active before the Mechanical Trip, however, if a high overload curve is chosen, the Mechanical Jam level and time delay become more critical. The setting should then be set to below the overload curve but above any normal overload conditions of the motor. The main purpose of the mechanical jam element is to protect the driven equipment due to jammed, or broken equipment. Undercurrent If detection of loss of load is required for the specific application, set the undercurrent element according to the current that will indicate loss of load. For example, this could be programmed for a pump application to detect loss of fluid in the pipe.

Unbalance Alarm and Trip

The unbalance settings are determined by examining the motor application and motor design. In this case, the motor being protected is a reciprocating compressor, in which unbalance will be a normal running condition, thus this setting should be set high. A setting of 20% for the Unbalance Alarm with a delay of 10 seconds would be appropriate and the trip may be set to 25% with a delay of 10 seconds Ground Fault Unfortunately, there is not enough information to determine a ground fault setting. These settings depend on the following information: 1. The Ground Fault current available. 2. System Grounding - high resistive grounding, solidly grounded, etc. 3. Ground Fault CT used. 4. Ground Fault connection - zero sequence or Residual connection. Acceleration Trip This setpoint should be set higher than the maximum starting time to avoid nuisance tripping when the voltage is lower or for varying loads during starting. If reduced voltage starting is used, a setting of 8 seconds would be appropriate, or if direct across the line starting is used, a setting of 5 seconds could be used. Start Inhibit This function should always be enabled after five successful starts to protect the motor during starting while it is already hot. The 369 learns the amount of thermal capacity used at start. If the motor is hot, thus having some thermal capacity, the 369 will not allow a start if the available thermal capacity is less than the required thermal capacity for a start. For more information regarding start inhibit refer to application note in section 7.6.6. Starts/Hour Starts/Hour can be set to the # of cold starts as per the data sheet.

For this example

the starts/hour would be set to 3. Time Between Starts In some cases, the motor manufacturer will specify the time between motor starts. In this example, this information is not given so this feature can be turned “Off”. However, if the information is given, the time provided on the motor data sheets should be programmed. Stator RTDs RTD trip level should be set at or below the maximum temperature rating of the insulation. This example has a class F insulation which has a temperature rating of 155°C, therefore the Stator RTD Trip level should be set to between 140°C to 155°C. The RTD alarm level should be set to a level to provide a warning that the motor temperature is rising. For this example, 120°C or 130°C would be appropriate. Bearing RTDs The Bearing RTD alarm and trip settings will be determined by evaluating the temperature specification from the bearing manufacturer.

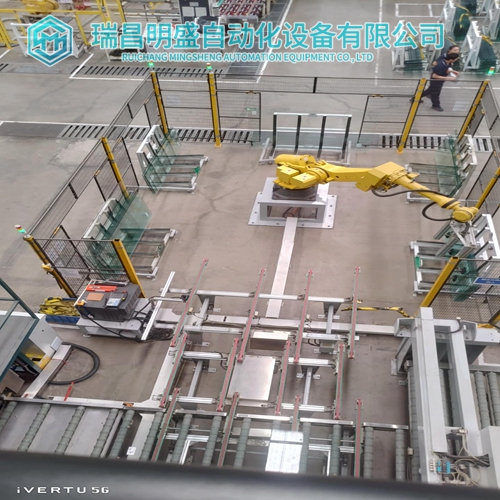

公司主营产品图展示

产品优势

1:国外专业的供货渠道,具有价格优势

2:产品质量保证,让您售后无忧

3:全国快递包邮

4:一对一服务

公司主营范围简介

PLC可编程控制器模块,DCS卡件,ESD系统卡件,振动监测系统卡件,汽轮机控制系统模块,燃气发电机备件等,优势品牌:Allen Bradley、BentlyNevada、ABB、Emerson Ovation、Honeywell DCS、Rockwell ICS Triplex、FOXBORO、Schneider PLC、GE Fanuc、Motorola、HIMA、TRICONEX、Prosoft等各种进口工业零部件、欧美进口模块。

产品广泛应用于冶金、石油天然气、玻璃制造业、铝业、石油化工、煤矿、造纸印刷、纺织印染、机械、电子制造、汽车制造、塑胶机械、电力、水利、水处理/环保、锅炉供暖、能源、输配电等等