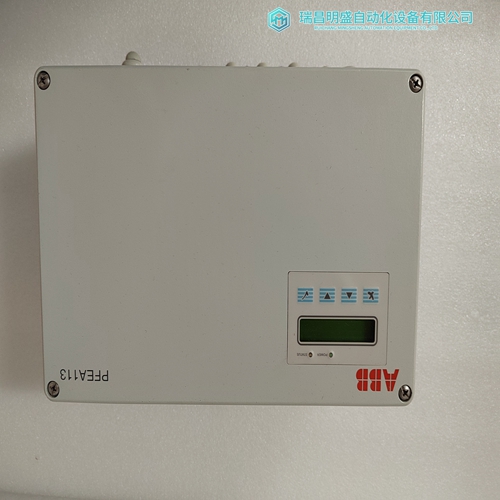

产品细节介绍

3BSE050092R65配套控制器

热容量使用量呈指数衰减,以模拟电机的冷却。冷却速度基于电机运行时的运行冷却时间常数,或电机运行时停止冷却时间常数停止。输入的冷却时间常数是总冷却时间的五分之一,从使用的100%热容量到使用的0%热容量。

369具有学习冷却时间常数的独特能力。仅当定子RTD与369相连。学习到的冷却时间算法在电机冷却时观察电机的温度,因此确定冷却所需的时间长度。如果无法从电机制造商处检索冷却时间,则必须启用学习冷却时间(如果定子RTD已连接)。

由于转子旋转,电机在运行时会产生扇形动作。因此,运行冷却时间通常为停止冷却时间的一半。

有关如何确定冷却时间常数的更多详细信息,请参阅冷却时间选择应用说明随电机一起提供。

RTD偏置这将使定子RTD传感器的温度包含在热容量计算中。这该模型根据定子温度确定了所用的热容量,是独立于用于计算所用热容量的过载模型。RTD偏置是一个备用保护元件比如失去冷却或环境温度异常高。有三个参数需要设置:RTD偏置最小值,RTD偏置中点,RTD偏置最大值。

RTD偏差最小值设置为40°C,即环境温度(从数据表中获得)。

RTD偏置中点

中心点温度设置为电机的热运行温度,计算如下:定子温升+环境温度。

根据数据表,定子的温升为79°K。因此,RTD中心点温度为设置为120°C(79+40)。

RTD偏差最大值

该设定值设置为绝缘额定值或稍低。该电机使用F级绝缘,额定值为155°C。

过载曲线

如果只提供了一条热极限曲线,则所选的过载曲线应位于其下方。当热极限和冷极限曲线,所选过载曲线应在两条曲线之间拟合,并使用编程的热/冷比在热容量算法中考虑电机的热状态。最佳拟合369标准曲线为曲线#4,如第7-9页图7-2:电机热极限所示。

短路跳闸

短路跳闸应设置为高于最大锁定转子电流,但低于保险丝的短路电流。

数据表显示最大堵转电流为550%FLC或5.5×FLC。具有瞬时延时的6×FLC设置将是理想的,但由于启动要求异常高,可能会导致误跳闸,而负载是耦合的。如果需要,将S/C级别设置为最高8×FLC,以覆盖这些条件。

PROGRAMMING EXAMPLE 7

The Thermal Capacity Used quantity decays exponentially to simulate the cooling of the motor. The rate of cooling is based upon the running cool time constant when the motor is running, or the stopped cool time constant when the motor is stopped. The entered cool time constant is one fifth the total cool time from 100% thermal capacity used down to 0% thermal capacity used. The 369 has a unique capability of learning the cool time constant. This learned parameter is only functional if the Stator RTDs are connected to the 369. The learned cool time algorithm observes the temperature of the motor as it cools, thus determining the length of time required for cooling. If the cool times can not be retrieved from the motor manufacturer, then the Learned Cool Time must be enabled (if the stator RTDs are connected). Motors have a fanning action when running due to the rotation of the rotor. For this reason, the running cool time is typically half of the stopped cool time. Refer to the Selection of Cool Time application note for more details on how to determine the cool time constants when not provided with the motor. RTD Biasing This will enable the temperature from the Stator RTD sensors to be included in the calculations of Thermal Capacity. This model determines the Thermal Capacity Used based on the temperature of the Stators and is a separate calculation from the overload model for calculating Thermal Capacity Used. RTD biasing is a back up protection element which accounts for such things as loss of cooling or unusually high ambient temperature.

There are three parameters to set

RTD Bias Min, RTD Bias Mid, RTD Bias Max. RTD Bias Minimum Set to 40°C which is the ambient temperature (obtained from data sheets). RTD Bias Mid Point The center point temperature is set to the motor’s hot running temperature and is calculated as follows: Temperature Rise of Stator + Ambient Temperature. The temperature rise of the stator is 79°K, obtained from the data sheets. Therefore, the RTD Center point temperature is set to 120°C (79 + 40). RTD Bias Maximum This setpoint is set to the rating of the insulation or slightly less. A class F insulation is used in this motor which is rated at 155°C. Overload Curve If only one thermal limit curve is provided, the chosen overload curve should fit below it. When a hot and cold thermal limit curve is provided, the chosen overload curve should fit between the two curves and the programmed Hot/Cold ratio is used in the Thermal Capacity algorithm to take into account the thermal state of the motor. The best fitting 369 standard curve is curve # 4, as seen in Figure 7–2: MOTOR THERMAL LIMITS on page 7–9. Short Circuit Trip The short circuit trip should be set above the maximum locked rotor current but below the short circuit current of the fuses. The data sheets indicate a maximum locked rotor current of 550% FLC or 5.5 × FLC. A setting of 6 × FLC with a instantaneous time delay will be ideal but nuisance tripping may result due to unusually high demanding starts or starts while the load is coupled. If need be, set the S/C level higher to a maximum of 8 × FLC to override these conditions.

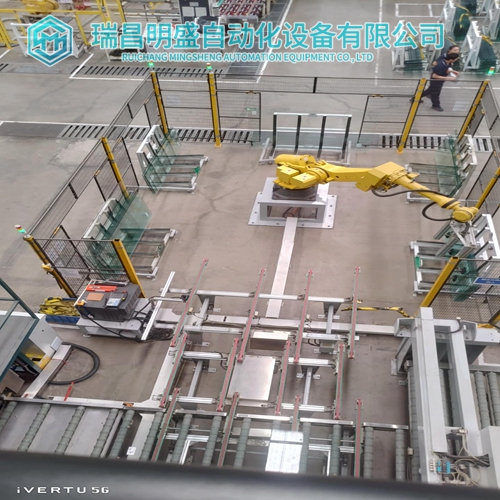

公司主营产品图展示

产品优势

1:国外专业的供货渠道,具有价格优势

2:产品质量保证,让您售后无忧

3:全国快递包邮

4:一对一服务

公司主营范围简介

PLC可编程控制器模块,DCS卡件,ESD系统卡件,振动监测系统卡件,汽轮机控制系统模块,燃气发电机备件等,优势品牌:Allen Bradley、BentlyNevada、ABB、Emerson Ovation、Honeywell DCS、Rockwell ICS Triplex、FOXBORO、Schneider PLC、GE Fanuc、Motorola、HIMA、TRICONEX、Prosoft等各种进口工业零部件、欧美进口模块。

产品广泛应用于冶金、石油天然气、玻璃制造业、铝业、石油化工、煤矿、造纸印刷、纺织印染、机械、电子制造、汽车制造、塑胶机械、电力、水利、水处理/环保、锅炉供暖、能源、输配电等等