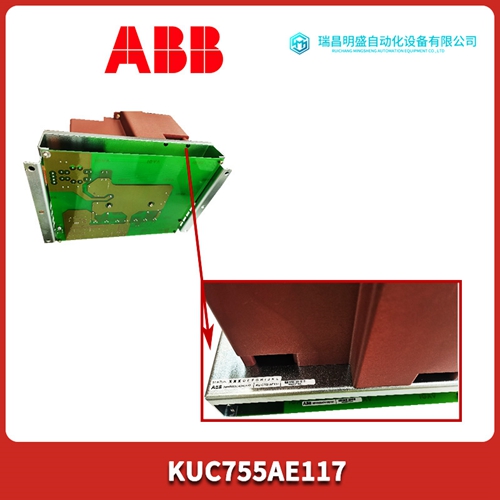

公司主营产品图展示

产品优势

1:国外专业的供货渠道,具有价格优势

2:产品质量保证,让您售后无忧

3:全国快递包邮

4:一对一服务

产品详情介绍

40PB3209A模拟量输出模块

外壳SMC Flex控制器的开放式设计要求将其安装在围墙。外壳内部温度必须保持在范围为0…50°C。

对于12型(IP54)外壳,表6中所示的指南如下建议限制控制器的最高环境温度。

顶部和底部至少应有15 cm(6 in.)的间隙控制器。该区域允许空气流过散热器。所有装置均采用风扇冷却。将控制器定位在某个位置很重要允许空气垂直流过电源模块。控制器必须安装在垂直平面上,且最小自由距离为15 cm(6 in.)控制器上方和下方的空间。

在软起动器附近钻孔或安装时,确保足够采取措施保护设备免受灰尘和碎屑的影响。见图27功率因数校正电容器控制器可以安装在具有功率因数校正的系统上电容器(PFCC)。电容器必须位于控制器。必须这样做,以防止损坏SMC Flex中的SCR控制器。

电容器放电时,阻抗基本为零。对于开关,应串联足够的阻抗电容器组以限制浪涌电流。

一种限制浪涌的方法电流会增加电容器导体的电感。

这可以是通过在与电容器。

•250V-15 cm(6 in.)直径线圈,6个回路

•480…690V-15 cm(6 in.)直径线圈,8个回路安装线圈时要小心,以免线圈直接堆放在彼此叠加会产生抵消效果。将线圈安装在绝缘材料上支架远离金属部件,因此它们不会用作感应加热器。如果使用隔离接触器,在接触器前放置电容器。

有关更多说明,请咨询PFCC供应商。可以安装包含金属氧化物压敏电阻(MOV)的保护模块在额定值为5…1250 A和200…600V的控制器上,以保护电源电气瞬变的部件。保护模块夹电压线路上产生的瞬变,以防止此类浪涌损坏SCR。

双速电机SMC Flex控制器具有单速过载保护电机。当SMC Flex控制器应用于双速电机时Overload Class(过载等级)参数必须编程为OFF(关闭)并单独过载必须为每个速度提供继电器。

Enclosures

The open-style design of the SMC Flex controller requires that it be installed in an enclosure. The internal temperature of the enclosure must be kept within the range of 0…50°C. For Type 12 (IP54) enclosures, the guidelines that are shown in Table 6 are recommended to limit the maximum controller ambient temperature. There should be a clearance of at least 15 cm (6 in.) above and below the controller. This area allows air to flow through the heatsink.

All units are fan cooled. It is important to locate the controller in a position that allows air to flow vertically through the power module. The controller must be mounted in a vertical plane and have a minimum of 15 cm (6 in.) free space above and below the controller. When drilling or installing near the soft starter, make sure that adequate measures are taken to protect the device from dust and debris. SeeFigure 27.

Two-speed Motors The SMC Flex controller has overload protection available for single speed motors. When the SMC Flex controller is applied to a two-speed motor, the Overload Class parameter must be programmed to OFF and separate overload relays must be provided for each speed.

Power Factor Correction Capacitors

The controller can be installed on a system with power factor correction capacitors (PFCCs). The capacitors must be located on the line side of the controller. This must be done to prevent damage to the SCRs in the SMC Flex controller. When it is discharged, a capacitor essentially has zero impedance. For switching, sufficient impedance should be connected in series with the capacitor bank to limit the inrush current. One method for limiting the surge current is to add inductance in the capacitor’s conductors. This can be accomplished by creating turns or coils in the power connections to the capacitors. • 250V — 15 cm (6 in.) diameter coil, 6 loops • 480…690V — 15 cm (6 in.) diameter coil, 8 loops Take care in mounting the coils so that they are not stacked directly on top of each other; stacking causes a canceling effect. Mount the coils on insulated supports away from metal parts so they will not act as induction heaters. If an isolation contactor is used, put capacitors in front of contactor. For further instructions, consult the PFCC vendor.Protective modules containing metal oxide varistors (MOVs) can be installed on controllers rated 5…1250 A and 200…600V, to protect the power components from electrical transients. The protective modules clip voltage transients generated on the lines to prevent such surges from damaging the SCRs.