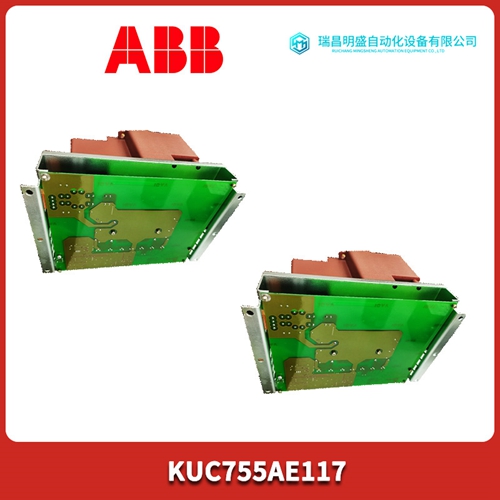

公司主营产品图展示

产品优势

1:国外专业的供货渠道,具有价格优势

2:产品质量保证,让您售后无忧

3:全国快递包邮

4:一对一服务

产品详情介绍

40PB3202A回路输入/输出卡

通过内置键盘和三行16字符背光LCD,编程设置非常简单。

参数组织在使用文本的三级菜单结构中

用于直接编程的格式。状态指示•标配四个可编程硬触点输出。全部的辅助触点可编程用于以下状态:

•正常(可选常开/常闭)

•最高速度(可选常开/常闭)

•警报(可选常开/常闭)

•故障(可选常开/常闭)

•网络控制(可选常开/常闭)

•外部旁路(仅N.O.)网络输入可通过选项输入#1的正确编程获得(参数132)和选项输入#2(参数24)。

接收控制员您有责任在验收前彻底检查设备货运公司的货物。根据采购订单。如果任何物品损坏,您有责任不在货运代理在货运单上注明损坏之前接受交货。

如果在开箱过程中发现任何隐藏的损坏,您的通知货运代理的责任。运输集装箱必须离开应要求货运代理目视检查设备。

打开控制器包装,从内部和周围移除所有包装材料、楔子或支架控制器。

检查控制器打开控制器包装后,检查产品铭牌目录号根据采购订单。

存储安装前,请将控制器放在运输集装箱中。

如果设备不能长期使用,必须存放为了保持保修,请按照以下说明操作新闻报道

•储存在干净、干燥的地方。

•保持环境温度范围为-20…+75°C(-4…+167°F)。

•储存在0%至95%的相对湿度范围内,无冷凝。

•不要将设备存放在可能接触腐蚀性物质的地方气氛

•不要将设备存放在施工区域。提升对于额定电流为625…1250 A的控制器,只能从指定的起吊点。吊点设计用于承受1/2…13能够提升2500磅的螺纹吊环。图26显示了提升点。本章介绍如何接收、解压缩和设置SMC™ 弯曲控制器。SMC Flex软起动器的防护等级为IP00或IP2X,具体取决于在尺寸上。您必须将设备安装在IP54(类型2)开关柜中,考虑到环境条件。确保没有灰尘、液体或导电部件可以进入软起动器。软起动器操作产生废热(热损失)。见表5或SMC-3™, SMC Flex和SMC-50™智能电机控制器技术数据,出版物150-TD009。散热量表5提供了额定电流下的最大散热量控制器。当电流低于额定值时,散热减少价值

Programming

Setup is easy with the built-in keypad and three-line, 16 character backlit LCD. Parameters are organized in a three-level menu structure that uses a text format for straightforward programming.Status Indication • Four programmable hard contact outputs are provided as standard. All auxiliary contacts are programmable for the following states: • Normal (selectable N.O./N.C.) • Up-to-Speed (selectable N.O./N.C.) • Alarm (selectable N.O./N.C.) • Fault (selectable N.O./N.C.) • Network Control (selectable N.O./N.C.) • External Bypass (N.O. only)This chapter explains how to receive, unpack, and set up the SMC™ Flex controller.The SMC Flex soft starters have an IP00 or IP2X protection rating, depending on the size. You must install the device in IP54 (Type 2) switchgear cabinets, taking into account the ambient conditions. Make sure that no dust, liquids, or conductive parts can enter the soft starter. Soft starter operation produces waste heat (heat loss). See Table 5 or the SMC-3™, SMC Flex, and SMC-50™ Smart Motor Controllers Technical Data, publication 150-TD009. Heat Dissipation Table 5 provides the maximum heat dissipation at rated current for the controllers. Heat dissipation is reduced for currents that are lower than rated value.

Receive the Controller

It is your responsibility to thoroughly inspect the equipment before accepting the shipment from the freight company. Check the item(s) received against the purchase order. If any items are damaged, it is your responsibility not to accept delivery until the freight agent has noted the damage on the freight bill. Should any concealed damage be found during unpacking, it is again your responsibility to notify the freight agent. The shipping container must be left intact and the freight agent should be requested to make a visual inspection of the equipment. Unpack the Controller Remove all packing material, wedges, or braces from within and around the controller. Inspect the Controller After you unpack the controller, check the item(s’) nameplate catalog number against the purchase order. Storage Keep the controller in its shipping container prior to installation. If the equipment is not to be used for an extended period, you must store it according to the following instructions in order to maintain warranty coverage. • Store in a clean, dry location. • Maintain an ambient temperature range of –20… +75 °C (–4…+167 °F). • Store within a relative humidity range of 0% to 95%, noncondensing. • Do not store equipment where it could be exposed to a corrosive atmosphere. • Do not store equipment in a construction area. Lifting For controllers rated 625…1250 A, the device should only be lifted from designated lifting points. The lifting points are designed to accept a 1/2…13 threaded hoist ring capable of lifting 2500 pounds. Figure 26 shows the lifting points.