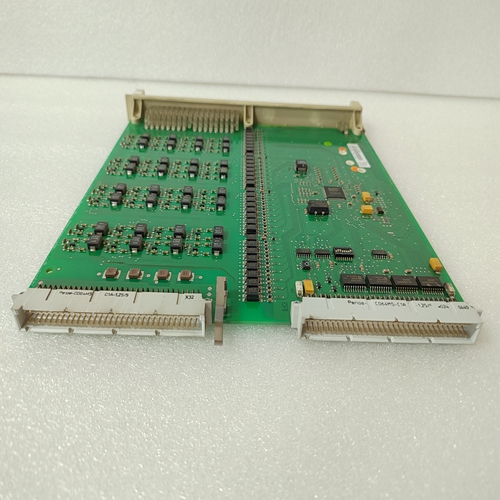

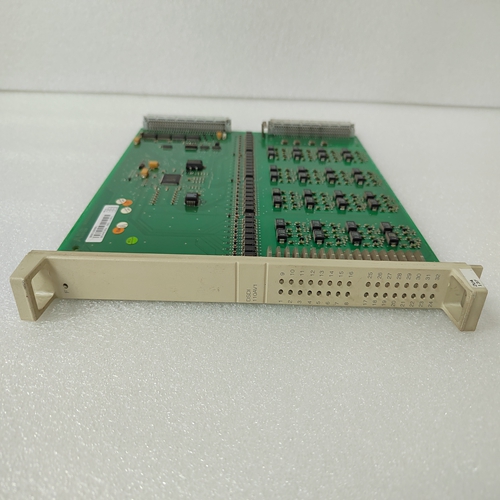

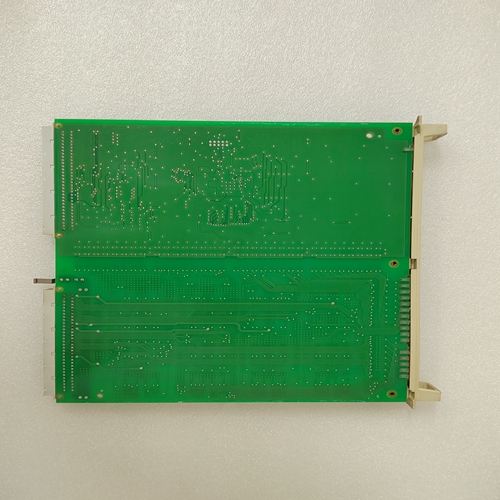

DSDI110AV1运动控制模块

扫描在总线控制器的扫描选项卡上,您可以使用最多32个字符。其余参数在FIP网络配置中设置工具此处不可编辑。

每个CPU扫描集都绑定到一个或多个已使用配置的时隙网络配置工具。在网络配置工具中定义的时隙用于分组类似的数据,如离散输入及其验证器。

通过CPU配置扫描集。它们控制PLC CPU如何将数据扫描到和来自总线控制器(和其他设备)。在90–70系列PLC中,FIP总线控制器扫描进出FIP的I/O数据

网络此扫描可以配置为与FIP网络。

PLC CPU扫描进出FIP总线控制器的I/O数据。同样,PLC CPU扫描可以被配置为与FIP总线控制器同步或异步。扫描集在PLC CPU中,I/O数据分组为扫描集。FIP总线控制器可以交换最多32个扫描集的数据。

扫描集是输入和/或输出数据的集合,用于满足PLC应用程序。例如,PLC应用程序可能需要处理所有离散输入和输出。另一个PLC应用程序可能需要:仅处理模拟输入和输出。

单个扫描集可能包含来自各种源的I/O数据。

例如扫描集可以将来自一个FIP总线控制器的离散输入和输出数据与来自另一FIP总线控制器的输入/输出数据,或来自PLC中本地输入/输出模块的输入/输入数据支架

PLC中有两种类型的扫描集:异步和同步。异步扫描集由PLC CPU扫描,不与任何同步FIP总线控制器。例如,可以对每个PLC扫描异步扫描集扫描,每20次PLC扫描等。只有当FIP总线控制器

已经消耗了来自网络的输入数据。FIP总线控制器通知:(触发)数据到达的PLC CPU,然后PLC CPU

安排应用程序并扫描输入数据。当申请程序完成后,PLC CPU扫描输出数据。这样,PLC

应用程序被称为与FIP网络同步。FIP巴士控制器可以交换多达15个同步扫描集的数据。

PLC CPU可同时配置同步和异步扫描集。对于每个同步扫描集,需要指定

必须触发扫描集的特定FIP总线控制器。同步扫描集可以仅由一个FBC触发。异步扫描集不需要或不允许触发器的规格。

Scanning

On the Bus Controller’s Scanning tab, you can enter a description of the scan set using

up to 32 characters. The rest of the parameters are set in the FIP Network Configuration

tool. They are not editable here.

Each CPU Scan Set is tied to one or more time slots that have been configured using the

Network Configuration tool.The time slots, which are defined in the Network Configuration tool, are used to group

similar data, such as discrete inputs and their validators.

Scan sets are configured via the CPU. They control how the PLC CPU scans data to and

from the bus controller (and other devices).In the Series 90–70 PLC, the FIP Bus Controller scans I/O data to and from the FIP

network. This scanning may be configured to be synchronous or asynchronous to the

FIP network.

The PLC CPU scans I/O data to and from the FIP Bus Controller. Likewise, the PLC CPU

scan may be configured to be synchronous or asynchronous to the FIP Bus Controller.

Scan Sets

In the PLC CPU, I/O data is grouped into scan sets. The FIP Bus Controller can exchange

data with up to 32 scan sets.

A scan set is a collection of input and/or output data that serves a specific I/O need of a

PLC application program. For example, a PLC application program may need to process

all of the discrete inputs and outputs. Another PLC application program may need to

process only the analog inputs and outputs.

An individual scan set may contain I/O data from a variety of sources. For example, a

scan set might combine discrete input and output data from one FIP Bus Controller with

I/O data from another FIP Bus Controller, or I/O data from a local I/O module in the PLC

rack.

There are two types of scan sets in the PLC: asynchronous and synchronous.

Asynchronous scan sets are scanned by the PLC CPU without any synchronization with

the FIP Bus Controller. For example, asynchronous scan sets may be scanned every PLC

sweep, every 20 PLC sweeps, etc.

Synchronous scan sets are scanned by the PLC CPU only when the FIP Bus Controller

has consumed the input data from the network. The FIP Bus Controller informs

(triggers) the PLC CPU of the arrival of the data and only then does the PLC CPU

schedule the application program and scan the input data. When the application

program completes, the PLC CPU scans the output data. In this manner, the PLC

application program is said to be synchronized with the FIP network. The FIP Bus

Controller can exchange data for up to 15 synchronous scan sets.

The PLC CPU may simultaneously be configured with both synchronous and

asynchronous scan sets. For each synchronous scan set it is necessary to specify the

particular FIP Bus Controller which must trigger the scan set. A synchronous scan set

may be triggered by only one FBC. Asynchronous scan sets do not require or permit the

specification of a trigger.