主营产品

PLC可编程控制器模块,DCS卡件,ESD系统卡件,振动监测系统卡件,汽轮机控制系统模块,燃气发电机备件等,优势品牌:Allen Bradley、BentlyNevada、ABB、Emerson Ovation、Honeywell DCS、Rockwell ICS Triplex、FOXBORO、Schneider PLC、GE Fanuc、Motorola、HIMA、TRICONEX、Prosoft等各种进口工业零部件

产品广泛应用于冶金、石油天然气、玻璃制造业、铝业、石油化工、煤矿、造纸印刷、纺织印染、机械、电子制造、汽车制造、塑胶机械、电力、水利、水处理/环保、锅炉供暖、能源、输配电等等

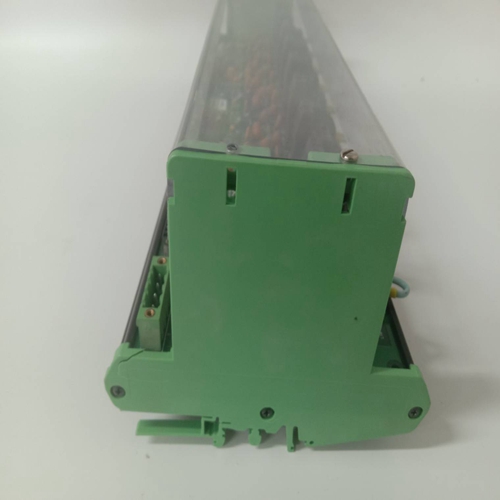

ICS T8846自动化控制卡件

冗余方案为协调每条线路的两个保护功能和一个或两个自动重合闸功能的运行而制定了规定端子(见图3.5.32.4和图3.5-32.5)。必须使用主/从逻辑来避免任何时间竞争由于定时器公差不同而导致的问题。

冗余方案采用第一和第二主保护每个方案都有自己的重合闸功能。操作

因此,重合闸功能必须通过将一个配置为“主”和另一个配置成“跟随器”来协调。如果主人

AR首先启动,它延迟跟随器AR的操作,直到已经成功地实现了重合闸或其他。

如果先启用跟随器AR,其死区时间开始运行,但如果主机在跟随器死区时间内启动,操作

随动器的重合闸功能暂停,主接管并执行其重合闸循环。

跟随器处于“热备用”状态,仅在主AR或其保护功能无法运行时才接管。

来自故障触点(如“CO就绪”)的信号发送至主机然而,重合闸将导致“Def”。跳闸后的输出时间“t超时”,这也会阻止跟随器AR。

在图3.5.32.4的电路中,主电路和从电路起作用也可以通过适当配置

系统软件。主/从逻辑

在1½断路器中提供主/从逻辑

每条线路具有两个线路保护和自动重合闸的方案每个断路器的功能。

其中一个重合闸功能由以下人员分配为主功能:

适当设置参数“主模式”。在成功重合闸之后,其CB(连接如图3.5.32.6所示

用于所有类型故障的三相跳闸和重合闸)。主重合闸功能向发送激活的“DELFLR”信号

跟随器的“主延迟”I/P将其“闭合CB”命令延迟到跟随器CB,直到主重合闸功能发出“闭合CB”,之后是等待时间作为一种预防措施,为成功重合闸留出时间。如果重合闸不成功,输出保持高

直到信号“Def”。“跳闸”被激活(“延迟Flwr”信号复位,并生成“Blk至Flwr”的信号)。

如果该信号在跟随器死区时间结束之前复位,

对跟随器CB的关闭命令在这是一个死时间。

Redundant schemes

Provision is made for coordinating the operation of two protection functions and one or two auto-reclosure functions per line

terminal (see Fig. 3.5.32.4 and Fig. 3.5.32.5).

A master/follower logic has to be used to avoid any time-race

problems due to differing timer tolerances.

A redundant scheme assumes first and second main protection

schemes each with its own reclosure function. The operation of

the reclosure functions therefore has to be coordinated by configuring one as ‘master’ and the other as ‘follower’. If the master

AR starts first, it delays the operation of the follower AR until it

has either achieved successful reclosure or otherwise.

If the follower AR is enabled first, its dead time starts to run, but

should the master start during the follow’s dead time, operation

of the follower reclosure function is suspended and the master

takes over and performs its reclosure cycle.

The follower is on “hot standby” and only takes over, if the master AR or its protection function fails to operate.

The signal from a faulty contact like ‘CO Ready’ to the master

recloser, however, would result in a ‘Def.Trip’ output after the

time ‘t Timeout’ and this would also block the Follower AR.

In the circuit of Fig. 3.5.32.4, the master and follower functions

can also be the other way round by appropriately configuring the

system software.Master/follower logic

Provision is made for a master/follower logic in 1½ breaker

schemes with two line protections per line and an auto-reclosure

function per circuit-breaker.

One of the reclosure functions is assigned the role of master by

appropriately setting the parameter ‘Master mode’. After a successful reclosure, the master AR then enables the follower AR,

respectively its CB (the connections are as given in Fig. 3.5.32.6

for a three-phase trip and reclosure for all types of faults).The master reclosure function sends an active ‘DelFlwr’ signal to

the ‘MasterDelay’ I/P of the follower to delay its ‘Close CB’ command to the follower CB until the master reclosure function issues the ‘Close CB’ command, which is followed by a wait time

of 300 ms as a precaution to allow time for a successful reclosure. If the reclosure is unsuccessful, the output remains high

until the signal ‘Def.Trip’ is activated (the ‘DelayFlwr’ signal resets and ‘Blk to Flwr’ signal is generated).

Should this signal reset before the end of the follower dead time,

the close command to the follower CB is issued at the end of the

dead time.