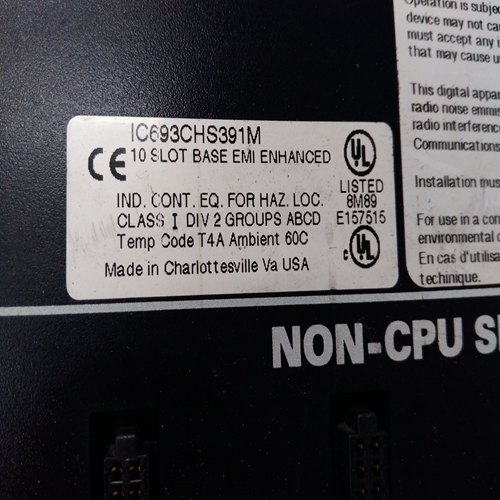

IC693CHS391库存备件

安装本节描述了Moore 353过程自动化控制器的安装。主题包括:安装

注意事项以及机械和电气安装。

重要的安装必须符合国家电气规范和所有其他要求适用的施工和电气规范。

第1.4.4节列出了典型控制器装运中的项目清单。如果显示器部件或电路板

必须安装在外壳中,有关安装信息,请参阅第11.5节“组件更换”,包括任何相关跳线的设置。

如有必要,请参阅第14.10节“机构批准”。CSA危险场所预防措施和特殊安全使用条件包括在本节中。设备的使用方式未经制造商可能会损害设备提供的保护。

8.1安装注意事项

Moore 353用于室内或室内无振动仪表板或机架中的嵌入式面板安装一个隐蔽的地方。在单站面板切口中安装单个控制器,或在中一行中安装多个控制器多工位面板断路器。对于水密面板,将每个控制器安装在一个单站切口中。

控制器提供了“直接进入连接器”或“侧面进入连接器”,第8.3节机械安装中显示了面板切口尺寸和控制器总体尺寸。控制器可以安装在用户提供的外壳中,位于室外或其位置:环境参数超过控制器操作规范。通常使用一条薄薄的硅密封胶在控制器的显示器组件和安装面板之间,以防止空气或液体在该接头处泄漏。

请勿将控制器安装在阳光直射可能撞击面板或外壳的地方。阳光直射可以使显示器难以读取,会干扰散热。

水平或向后倾斜安装控制器(即外壳前部高于后部)。如果控制器应安装一些电子记录器或气动记录器或工作站,后倾这些单元的限制可能会影响面板设计和布局。

通过清晰标记的断路器、保险丝或开关将电力输送至控制器位于控制器附近,操作员可接近。断路器或开关应位于非爆炸性环境中,除非适用于爆炸性环境。热电偶输入与I/O扩展板和参考结温度传感器相适应。在工厂,范围电阻器和参考安装套件中包括两个参考接头。第11.3节“故障排除”和第11.5节“组装”讨论了MPU控制器板上的跳线替换安装或存储控制器或MPU控制器板时,请参阅本材料。

8.2环境考虑

在其环境规范范围内运行控制器,以帮助确保可靠、无故障运行

最小停机时间。参考第14.8节了解控制器工作温度限制、工作湿度和最大含水量。

INSTALLATION This section describes installation of a Moore 353 Process Automation Controller. Topics include: installation considerations and mechanical and electrical installation. IMPORTANT The installation must conform to the National Electrical Code and all other applicable construction and electrical codes. Section 1.4.4 has a list of the items in a typical controller shipment. If the Display Assembly or a circuit board(s) must be installed in the case, go to Section 11.5 Assembly Replacement for installation information, including the setting of any involved jumpers. Refer to Section 14.10 Agency Approvals as necessary. CSA Hazardous Location Precautions and Special Conditions for Safe Use are included in this section. Use of the equipment in a manner not specified by the manufacturer may impair the protection provided by the equipment. 8.1 INSTALLATION CONSIDERATIONS A Moore 353 is intended for flush panel mounting in a vibration free instrument panel or rack in an indoor or sheltered location. Mount a single controller in a single-station panel cutout or mount several controllers in a row in a multiple-station panel cutout. For a watertight panel, mount each controller in a single-station cutout. Controllers have been supplied with either “direct entry connectors” or “side entry connectors.” Connector types, panel cutout dimensions, and overall controller dimensions are shown in Section 8.3 Mechanical Installation. The controller can be mounted in a user-supplied enclosure located out-of-doors or in a location whose environmental parameters exceed controller operating specifications. A thin bead of silicon sealant is often applied between the controller’s Display Assembly and the mounting panel to prevent air or liquid leakage at this joint. Do not mount the controller where direct sunlight can strike the faceplate or case. Direct sunlight can make the displays difficult to read and will interfere with heat dissipation. Mount the controller either horizontally or with a backward tilt (i.e. the front of the case higher than the rear). If the controller is to be mounted with some electronic recorders or with pneumatic recorders or stations, tilt back restrictions for these units can have a bearing on panel design and layout. Route electrical power to the controller through a clearly labeled circuit breaker, fuse, or on-off switch that is located near the controller and is accessible by the operator. The breaker or switch should be located in a nonexplosive atmosphere unless suitable for use in an explosive atmosphere. Thermocouple inputs are accommodated with an I/O Expander board and a Reference Junction temperature sensor. At the factory, two Reference Junctions are included in a Range Resistor and Reference Installation Kit. Jumpers on the MPU Controller board are discussed in Sections 11.3 Troubleshooting and 11.5 Assembly Replacement. Refer to this material when installing or storing a controller or an MPU Controller board. 8.2 ENVIRONMENTAL CONSIDERATIONS Operate a controller within its environmental specifications to help ensure reliable, trouble-free operation with minimum down time. Refer to Section 14.8 for controller operating temperatures limits, operating humidity, and maximum moisture content.