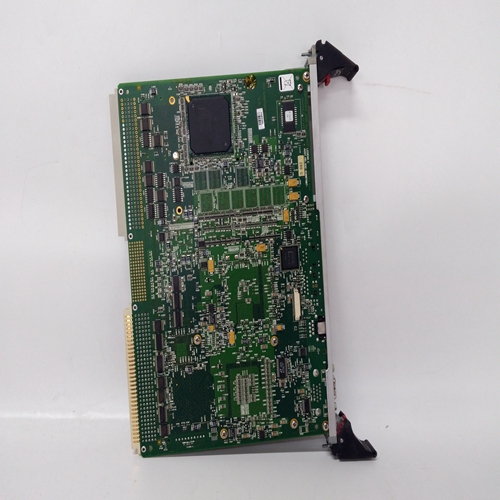

VMIVME-017807-414001燃机模块

当输入A为高(1)时,控制器将在正常自动模式,当低(0)时,使复位R跟踪

(F-GE)。这将强制控制器输出跟踪控制器限制内的反馈,并允许控制器在不影响输出的情况下切换回自动。过程范围指针参数(输入R)指向具有范围缩放的功能块,如模拟提供过程变量的输入。这使得控制器,用于规范化工艺范围。如果未配置此参数,则控制器将使用0.00-100.00的范围缩放。

输入I,当从低(0)变为高(1)或从从高到低将导致控制器初始化(即。在该扫描期间消除任何比例增益动作周期这可用于防止碰撞输出使用开关更改设定点时块通电-在暖机或冷机通电期间,输出将初始化为最小刻度和所有动态元素将在第一次扫描时在当前输入处初始化。输入AG乘以增益误差(GE)。在控制器固件版本1.30中,未连接的AG输入将设置为1.0。在早期版本中,它设置为0.0,这要求输入始终连接到源(例如保持块),以便PIDAG块起作用。控制器输出具有MINSCALE和MAXSCALE参数,允许对输出信号进行缩放工程范围,而不是默认值0-100 PRCT。当控制器输出为设置点到另一个控制器。

当自动调谐设置为“是”时,可使用调谐按钮访问自动调谐功能

并且可以:在回路处于自动或手动状态时启动。自动调谐器启动后,将用开关代替PIDAG控制功能,将A/M模块置于Auto(如果处于Man),并通过六个开-关周期循环控制回路同时学习其用于为PIDAG控制器提供调谐建议的过程动力学。%DEV参数是在开关周期。该参数可以手动设置,也可以配置为自动。配置“自动”时自动调谐将%DEV设置为%HYS的4倍。这是提供良好自动调谐所需的最小值后果%HYS参数是在中切换输出之前过程必须偏离设定值的量相反的方向。该值必须至少等于或略大于任何工艺噪声带。如果噪音无法确定频带,当%HYS参数已配置为自动。%阶跃参数是阀门在第一个开-关循环中的变化量。在第一个循环之后autotuner将调整步长,以将进程保持在%DEV参数的值内。随后自动调谐练习,该步骤将使用从上一练习计算的值,除非AT RESET参数设置为“是”或控制器已通电。自动调谐建议的动态响应可以是:配置为快速、中等或慢速。介质设置通常会提供一个没有或很少的响应超调至设定点阶跃响应。当POST AT参数设置为YES时,控制回路将使用推荐的调整值,除非测试期间出现警告。有关自动调谐的更多详细信息,请参见操作部分。

When input A is high (1) the controller will operate in the

normal auto mode and when low (0) causes reset R to track

(F-GE). This forces the controller output to track the

feedback within controller limits and allow the controller

to be switched back to auto without bumping the output.

The process range pointer parameter (input R) points to a

function block that has range scaling, such as the analog

input that is providing the process variable. This enables

the controller to normalize the tuning parameters for the

process range. If this parameter is not configured, the

controller will use a range scaling of 0.00-100.00.

Input I, when changed from low (0) to high (1) or from

high to low, will cause the controller to initialize (i.e.

eliminate any proportional gain action during that scan

cycle. This can be used to prevent bumping the output

when changes are made to the setpoint using a switch

block. POWER UP - During a warm or cold power up, the output will be initialized to MINSCALE and all dynamic

elements will be initialized at the current input on the first scan.

Input AG is multiplied by the gain error (GE). In version 1.30 of the controller firmware, an unconnected AG input

will be set to 1.0. In earlier versions, it was set to 0.0 which required that the input always be connected to a source

(e.g. Hold block) in order for the PIDAG block to function.

The controller output has MINSCALE and MAXSCALE parameters allowing the output signal to be scaled for

engineering ranges other than the default of 0 - 100 PRCT. This may be necessary when the controller output is the

setpoint to another controller.

The Autotune feature is accessible using the TUNE pushbutton when AUTOTUNE is set to YES and can be

initiated while the loop is in Auto or Manual. The autotuner, when initiated, replaces the PIDAG with an on-off

control function, places the A/M block in Auto (if in Man) and cycles the control loop through six on-off cycles

while learning the process dynamics which it uses to provide tuning recommendations for the PIDAG controller.

The % DEV parameter is the maximum amount in % that the process should deviate from the setpoint during the

on-off cycles. This parameter can be set manually or can be configured as AUTO. When AUTO is configured, the

autotuner will set the % DEV to 4 times the % HYS. This is the minimum value needed to provide good autotuning

results.

The % HYS parameter is the amount that the process must deviate from setpoint before switching the output in the

opposite direction. This value must be at least equal to or slightly greater than any process noise band. If the noise

band cannot be determined, the autotuner will compute it at the start of an autotuning exercise when the % HYS

parameter has been configured as AUTO. The % STEP parameter is the amount that the valve will change on the first on-off cycle. After the first cycle, the

autotuner will adjust the step to keep the process within the value of the % DEV parameter. On subsequent

autotune exercises, the step will use the value computed from the previous exercise unless the AT RESET parameter

is set to YES or the controller has been power cycled. The dynamic response recommended by the autotuner can be

configured as Fast, Medium, or Slow. The Medium setting will normally provide a response that has no or little

overshoot to a setpoint step response.

When the POST AT parameter is set to YES, the control loop will be returned to Auto using the recommended

tuning values unless a warning occurred during the test.

More details on autotuning can be found in the Operation section.