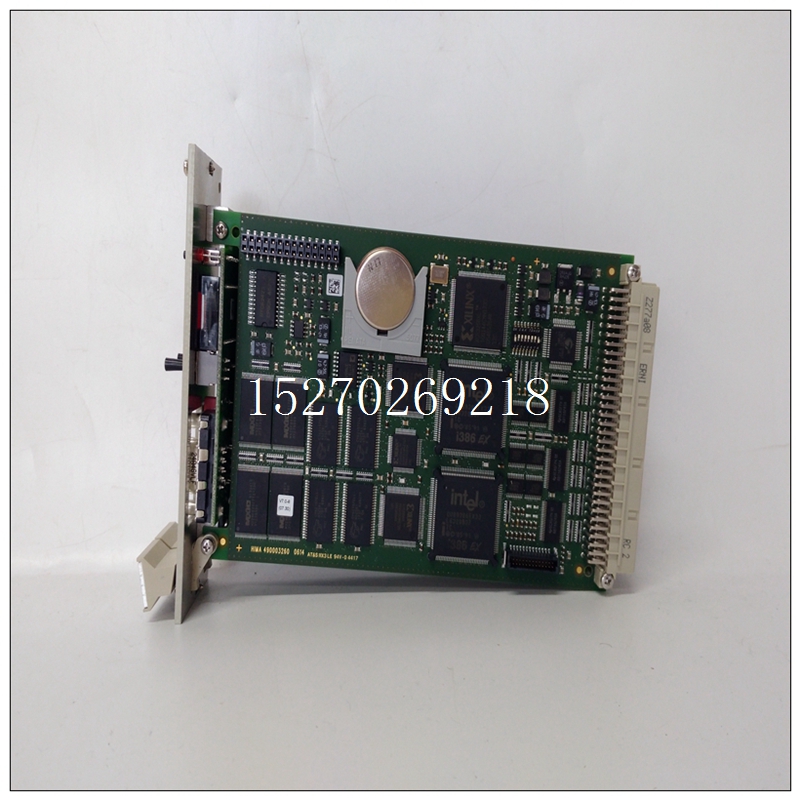

HIMA F6214处理器卡件

以太网板支持通过以太网LAN上传和下载控制器配置。对于例如,如果在图1-2所示的本地客户端上加载i|config图形配置实用程序软件,可以在客户端上开发控制器配置,或从控制器上传以进行编辑,然后下载到控制器。还可以从远程服务器获取数据,用于存档和/或数据挖掘。图1-2中的以太网Modbus网桥接受来自控制器的以太网数据命令,并且向地址1处的Modbus设备输出等效Modbus命令。返回的Modbus数据被嵌入

由网桥在以太网分组中发送到请求控制器。

无论所选通信选项如何,显示屏组件下侧的RS232端口将使用Modbus通信。控制器硬件架构设计用于适应其他新兴的现场总线技术。这包括需要较低功率以实现本质安全和较高速度的现场通信植物间网络。

对于小型改装应用,带有操作员面板的Moore 353可替代简单的单机

单回路控制器。它很容易升级,具有用于高级控制的额外I/O和通信选项策略和工厂网络。

在本出版物中,通常会参考控制器上的标签,以确保正在安装的控制器

具有正确的电源输入、I/O、通信选项和批准。当存在非易燃要求或涉及关键过程时,这一点尤为重要,其中自定义配置或校准具有:

已创建。标签位置如图1-1所示,典型标签如第14节“型号名称”所示以及规格。

1.2功能块

控制器软件基于以前的LIL产品和西门子的成熟功能块设计

支持IEC1131标准的APACS®产品。在许多情况下,控制器已通过只有现在最先进的技术才能提供这些功能。选择功能块在循环中使用。可以配置多个环路,每个环路可以

与操作员面板相关联。某些块在每个循环内使用一次(例如,自动/手动),其他的可以根据需要多次使用。一些值得注意的功能包括在

PID功能块,一个可扩展的定序器,允许配置多达250个步骤和多达256个离散输入和输出。此外,图形配置实用程序可用于设计梯形图中的逻辑

简图将这些功能与同一控制器内的连续控制回路相结合,为小批量操作提供了良好的集成解决方案。

站级有几个功能块可用于配置站级参数,如车站地址和车站标签名称。功能块包括时钟块(当RTC/CB选项

已包括板)和以太网块(当安装了以太网板和控制器时包含固件V2.4或更高版本)以配置诸如IP地址的参数。所有其他功能块包括:

用于单个循环内的配置。在摩尔353中,通过以下方式配置控制实现:

首先创建一个循环,然后输入一个唯一的循环标记名,并选择在该循环中使用的功能块。A.在Moore 353中可以配置多个回路,并且多种功能块类型可用:将在下面的章节中描述。

The Ethernet board supports uploading and downloading of controller configurations over the Ethernet LAN. For

example, if i|config Graphical Configuration Utility software is loaded on the local client shown in Figure 1-2,

controller configurations can be developed on the client, or uploaded from the controller for editing, and then

downloaded to the controller. Data can also be acquired from remote servers for the purpose of archiving and/or

data mining. The Ethernet-Modbus Bridge in Figure 1-2 accepts an Ethernet data command from the controller and

outputs an equivalent Modbus command to a Modbus device at address 1. The returning Modbus data is embedded

by the bridge in an Ethernet packet to be sent to the requesting controller.

Regardless of the selected communication option, the RS232 port on the underside of the Display Assembly will

communicate using Modbus. Controller hardware architecture is designed to accommodate other emerging fieldbus

technologies. This includes field communications that require lower power for intrinsic safety and higher speed for

interplant networking.

For small retrofit applications, the Moore 353 with operator faceplate is a replacement for a simple stand-alone

single-loop controller. It is easily upgraded with additional I/O and communication options for advanced control

strategies and plant networking.

Often in this publication, reference is made to the labels on the controller to ensure that the controller being installed

has the correct power input, I/O, communication options, and approvals. This is particularly important when nonincendive requirements are present or a critical process is involved where a custom configuration or calibration has

been created. Label locations are shown in Figure 1-1 and typical labels are shown in Section 14 Model Designation

and Specifications.

1.2 FUNCTION BLOCKS

Controller software is built on proven function block designs from previous LIL products and from Siemens

APACS® products that support the IEC1131 standard. In many cases, the controller has been enhanced with

features only now possible with state of the art technology.

Function blocks are selected for use within a LOOP. Multiple loops can be configured, and each loop can be

associated with an operator faceplate. Certain blocks are used once within each loop (e.g. controller, setpoint,

auto/manual), others can be used as many times as needed. Some notable features include Auto Tuning within the

PID function blocks, an expandable Sequencer that allows configuration of up to 250 steps, and up to 256 discrete

inputs and outputs. In addition, the Graphical Configuration Utility can be used to design the logic in a ladder

diagram. Combining these features with continuous control loops within the same controller offers a wellintegrated solution for small batch operations.

Several function blocks are available at the station level for configuration of STATION level parameters, such as

the station address and station tag name. Function blocks include the CLOCK block (when the RTC/CB option

board has been included), and the ETHERNET block (when the Ethernet board has been installed and the controller

contains firmware V2.4 or higher) to configure parameters such as the IP address. All other function blocks are

used for configuration within an individual LOOP. Control implementations are configured in the Moore 353 by

first creating a loop, then entering a unique loop tag name and selecting function blocks for use within that loop. A

number of loops can be configured in the Moore 353 and a number of function block types are available as

described in the sections that follow.