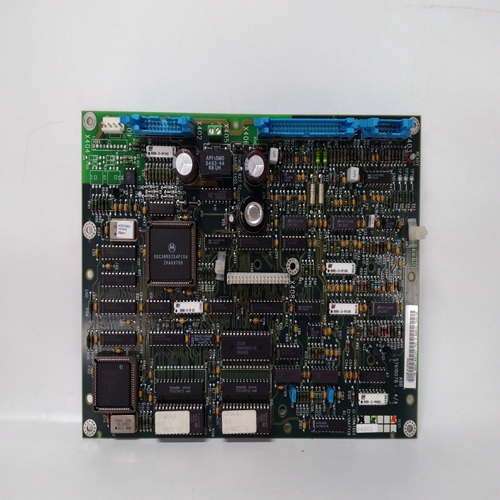

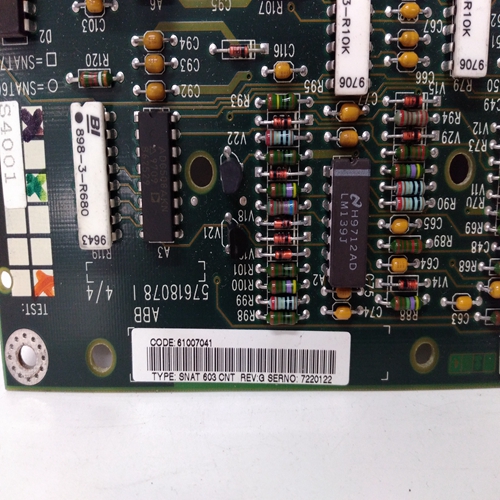

SNAT603CNT工控卡件

全体的PFTL 101系列中的称重传感器有六个不同的测量范围,从0.5到20kN和两种不同尺寸(见2.2技术数据)。每个称重传感器都经过单独校准,并且温度补偿。

称重传感器通常用六个螺钉(四个)安装并固定在底座和轴承箱上在称重传感器的一侧,两个在相对侧。

对于PFTL 101型的所有称重传感器,称重传感器外壳由一块钢加工而成。

然后将传感器焊接到称重传感器室内,并进行定向,使其对测量方向,对其他方向不敏感。

PFTL101A、PFTL 101AE、PFTL101B和PFTL 101 BE型称重传感器由不锈钢制成钢

PFTL101a和PFTL 101B配备有用于可插拔连接电缆的连接器。

PFTL 101AE和PFTL 101 BE配备有固定连接电缆。

PFTL 101AER和PFTL 101 BER型称重传感器是专为安装在腐蚀环境中而设计的

环境它们由耐酸不锈钢制成,并具有固定连接缆绳

图纸中给出了所有称重传感器类型的尺寸。精度和精度等级

精度等级定义为最大偏差,并表示为标称负载下灵敏度的百分比。这包括线性偏差、滞后和重复性误差。

线性偏差

线性偏差是与输出值之间绘制的直线的最大偏差

在零负载和标称负载下。线性偏差与灵敏度有关。迟滞

滞后是在从零开始的一个周期内,相同负载下输出信号的最大差值

负载到标称负载和回到零负载,与标称负载下的灵敏度相关。滞后

压力传感器的压力与负载周期成比例。重复性误差

重复性误差定义为相同条件下重复读数之间的最大偏差

条件它表示为标称负载下灵敏度的百分比。

补偿温度范围

在一定温度下,称重传感器的温度漂移已得到补偿

范围。即规定允许温度漂移的温度范围(即。零点和灵敏度漂移)。

General

The load cells in the PFTL 101 family are available in six different measuring ranges from 0.5 to 20

kN and two different sizes (see 2.2 Technical Data). Each load cell is individually calibrated and

temperature compensated.

The load cells are usually mounted and fixed to a base and a bearing housing with six screws, four

on one side of the load cells and two on the opposite side.

For all load cells of type PFTL 101 the load cell house is machined from a single block of steel.

A sensor is then welded into the load cell house and oriented so that it is sensitive to force in the

direction of measurement and insensitive in other directions.

The load cell types PFTL 101A, PFTL 101AE, PFTL 101B and PFTL 101BE are made of stainless

steel.

PFTL 101A and PFTL 101B are equipped with a connector for the pluggable connection cable.

PFTL 101AE and PFTL 101BE are equipped with a fixed connection cable.

Load cell types PFTL 101AER and PFTL 101BER are specially designed for installation in corrosive

environment. They are made of acid resistant stainless steel and they also have a fixed connection

cable.

Dimensions for all load cell types are given in A Drawings.Accuracy and Accuracy Class

Accuracy class is defined as the maximum deviation, and is expressed as a percentage of the sensitivity at nominal load. This includes linearity deviation, hysteresis and repeatability error.

Linearity Deviation

Linearity deviation is the maximum deviation from a straight line drawn between the output values

at zero load and nominal load. Linearity deviation is related to the sensitivity. Hysteresis

Hysteresis is the maximum difference in the output signal at the same load during a cycle from zero

load to nominal load and back to zero load, related to the sensitivity at nominal load. The hysteresis

of a Pressductor transducer is proportional to the load cycle. Repeatability error

Repeatability error is defined as the maximum deviation between repeated readings under identical

conditions. It is expressed as a percentage of the sensitivity at nominal load.

Compensated temperature range

The temperature drifts of the load cell have been compensated for in certain temperature

ranges. That is the temperature range within which the specified permitted temperature drifts (i.e.

zero point and sensitivity drifts) of the load cell are maintained.