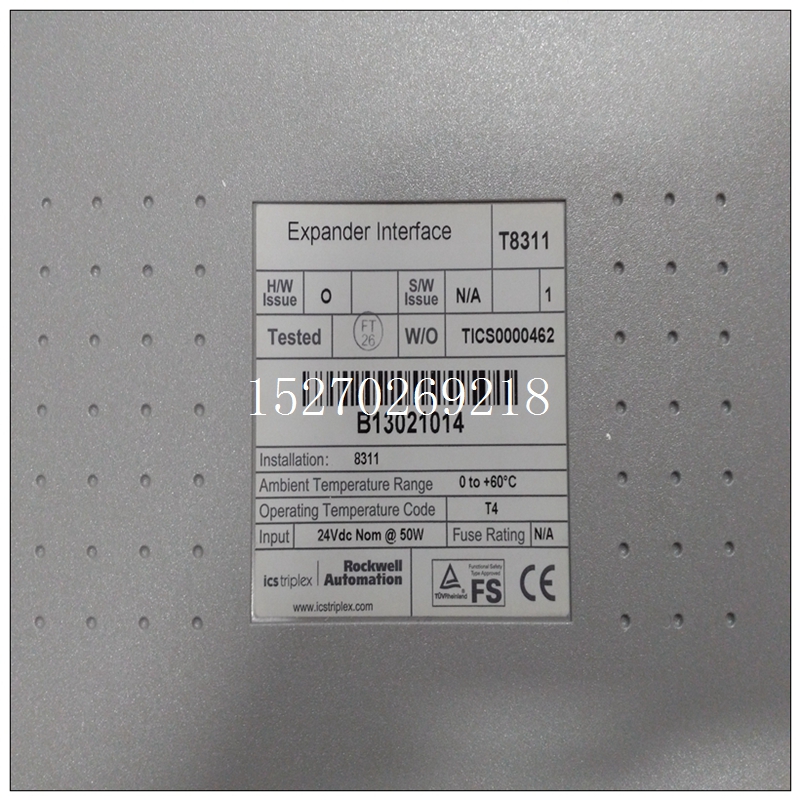

ICS TRIPLEX T8311可编程输入模块

若是机内调节,应放在印刷板上方便调节的地方;若是机外调节,其位置要与调节旋钮在机箱面板上的位置相适应。

留出印刷板定位孔及固定支架所占用的位置。一般元器件布局

根据电路的功能单元,对电路的全部元器件进行布局时,要符合以下原则:

按照电路的流程安排各个功能电路单元的位置,使布局便于信号流通,并使信号尽可能保持一致的方向。

ICS TRIPLEX T8311可编程输入模块② 以每个功能电路的核心元件为中心,围绕它来进行布局。元器件应均匀、整齐、紧凑地排列在PCB上,尽量减少和缩短各元器件之间的引线和连接。

③ 在高频下工作的电路,要考虑元器件之间的分布参数。一般电路应尽可能使元器件平行排列,这样,不但美观,而且装焊容易,易于批量生产。

④ 位于电路板边缘的元器件,离电路板边缘一般不小于2 mm。电路板的最佳形状为矩形。长宽比为3:2或4:3。电路板面尺寸大于200 mm×150 mm时,应考虑电路板所受的机械强度。

3、布线布线的原则如下:

① 输入输出端用的导线应尽量避免相邻平行,最好加线间地线,以免发生反馈耦合。

② 印刷板导线的最小宽度主要由导线与绝缘基板间的粘附强度和流过它们的电流值决定。当铜箔厚度为0.5 mm、宽度为1~15 mm时,通过2 A的电流,温升不会高于3℃。因此,导线宽度为1.5 mm可满足要求。对于集成电路,尤其是数字电路,通常选0.02~0.3 mm导线宽度。当然,只要允许,还是尽可能用宽线,尤其是电源线和地线。导线的最小间距主要由最坏情况下的线间绝缘电阻和击穿电压决定。对于集成电路,尤其是数字电路,只要工艺允许,可使间距小于0.1~0.2 mm。

Traditional Ethernet is not designed for industrial application, and does not consider the adaptability of industrial field environment. The mechanical, climatic, dust and other conditions on the industrial site are very bad, so higher requirements are put forward for the industrial reliability of the equipment, and the application in some high-risk fields is even extremely harsh.

In order to solve the problem that the network can work stably under extreme conditions in the field of industrial application, rail hub and industrial Ethernet switch products are launched, which are installed on the standard DIN rail and powered by redundant power supply.

With the continuous innovation and improvement of industrial Ethernet technology, the application range of industrial Ethernet is wider. At present, industrial Ethernet is not only widely used in factory automation production in many fields such as home appliance manufacturing and automobile manufacturing, but also widely used in many industries such as intelligent