GIDINGS&LEWIS M.1019.2447通信模块 PDF资料

1.产 品 资 料 介 绍:

GIDINGS&LEWIS M.1019.2447 通信模块

产品概述

GIDINGS&LEWIS M.1019.2447 通信模块是一种工业自动化系统中的功能模块,主要用于控制器与其他模块或外部设备之间的高速数据通信。该模块能够保证控制指令、状态信号以及传感器数据的实时传输,确保系统内部各功能单元的协调运行。广泛应用于数控机床、自动化生产线、伺服与运动控制系统,是工业控制系统中的关键信息接口。

技术参数(典型特性,实际数值需参考官方资料)

功能定位:高速数据通信与信号接口

接口类型:工业总线接口或点对点通信接口

传输速率:支持高速数据交换,满足实时控制要求

协议支持:可支持多种工业通信协议(具体取决于系统配置)

信号隔离:电气隔离设计,增强抗干扰能力

安装方式:模块化插槽式,便于维护和扩展

环境适应性:工业级设计,可适应高温、振动和电磁干扰环境

应用场景

数控机床 (CNC)

连接主控系统与伺服驱动、I/O 模块,实现加工指令与反馈信号的同步传输。

自动化生产线

用于工作站之间的数据传输,实现工艺协调与生产节拍控制。

伺服与运动控制系统

在机器人、多轴平台及电机控制系统中提供实时通信,保证位置、速度及扭矩控制精度。

过程控制行业

在冶金、化工、造纸等连续生产系统中,实现各子系统的数据流通与状态同步。

能源与电力系统

在发电机组、变电站及大型电气设备中,提供控制系统与监测设备之间的高速通信,提高运行可靠性。

英文资料:

GIDINGS&LEWIS M.1019.2447 Communication Module

Product Overview

GIDINGS&LEWIS M.1019.2447 communication module is a functional module in industrial automation systems, mainly used for high-speed data communication between controllers and other modules or external devices. This module can ensure real-time transmission of control instructions, status signals, and sensor data, ensuring the coordinated operation of various functional units within the system. Widely used in CNC machine tools, automated production lines, servo and motion control systems, it is a key information interface in industrial control systems.

Technical parameters (typical characteristics, actual values need to refer to official materials)

Functional positioning: high-speed data communication and signal interface

Interface type: Industrial bus interface or point-to-point communication interface

Transmission rate: Supports high-speed data exchange and meets real-time control requirements

Protocol Support: Supports multiple industrial communication protocols (depending on system configuration)

Signal isolation: Electrical isolation design enhances anti-interference capability

Installation method: Modular slot type, easy to maintain and expand

Environmental adaptability: Industrial grade design that can adapt to high temperature, vibration, and electromagnetic interference environments

Application scenarios

Numerical Control Machine Tool (CNC)

Connect the main control system with servo drives and I/O modules to achieve synchronous transmission of machining instructions and feedback signals.

Automatic production line

Used for data transmission between workstations to achieve process coordination and production cycle control.

Servo and motion control system

Provide real-time communication in robots, multi axis platforms, and motor control systems to ensure accuracy in position, speed, and torque control.

Process control industry

Realize data flow and status synchronization of various subsystems in continuous production systems such as metallurgy, chemical engineering, and papermaking.

Energy and Power Systems

Provide high-speed communication between control systems and monitoring equipment in generator sets, substations, and large electrical equipment to improve operational reliability.

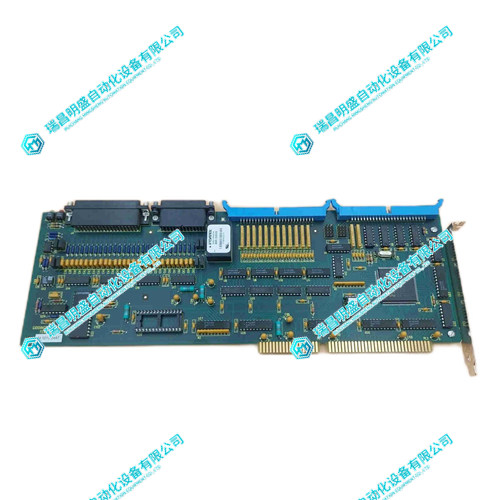

2.产 品 展 示

3.其他产品

193X256ABG01放大器

193X256AAG02电动电路板

ZM-16-PKZ2接触器

4.其他英文产品

5SHY35L4520 5SXE10-0181 AC10272001R0101 Thyristor module

AUTOMATIONX AXLINK100 892.202988 module

HONEYWELL CC-PAIX01 Sequence control module

| PXI-4060 | PPD113B03-26-100110 | 3500/65 |

| PXI-2598 | Gespac GESSIO-2 SIO-2 | 3500/92 136180-01 |

| PXI-2593 | Gespac GESPIA-2A | XV371A |

| PXI-2586 | PPA322B HIEE300016R2 HIEE400235R1 | SMIO-01C |

| PXI-2569 | Gespac 03-322711A03 GESOUT-3 | 3500/25 125792-01 |

| PXI-2567 | GESPAC RVC-1000.MC1 | CI630 3BSE011000R1 |

| PXI-2565 | PFTL101B 20KN 3BSE004203R1 | 125800-02 |

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs