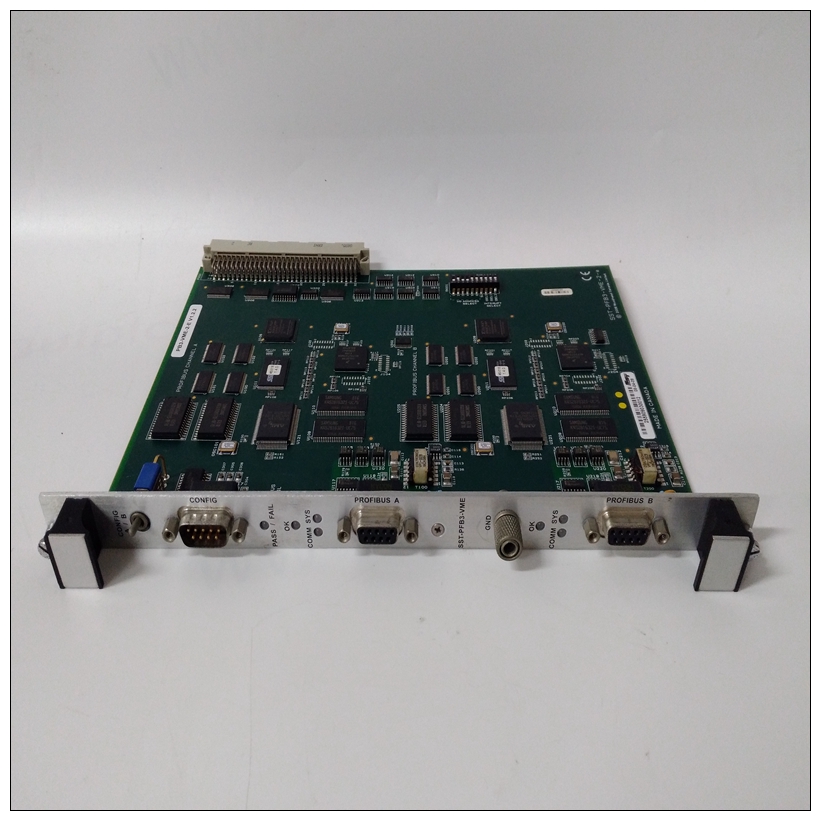

SST-PFB3-VME控制模块,SST使用书

软件可编程硬件中断提供了八个软件可编程硬件中断通过VMEchip2。这些中断允许软件创建硬件中断。本地总线超时MVME187为本地总线提供超时功能。什么时候计时器启用,本地总线访问超时,传输错误确认(TEA)信号被发送到本地总线主机。这个超时值可由软件选择8微秒、64微秒、256微秒、,或无限。

SST-PFB3-VME控制模块本地总线计时器在VMEbus期间不工作绑定周期。VMEbus绑定周期由VMEbus计时访问计时器和VMEbus全局计时器。内存映射内存映射有两种观点:1、本地总线内存映射–本地总线查看的所有资源的映射大师级

2.VMEbus内存映射–VMEbus查看的车载资源映射本地总线内存映射本地总线内存映射通过以下方式拆分为不同的地址空间:传输类型(TT)信号。当地资源对正常访问和中断确认代码。

正常地址范围设备响应正常地址的设备的内存映射范围如下表所示。正常地址范围为由本地总线上的传输类型(TT)信号定义。❏ 在MVME187上,传输类型0和1定义法线地址范围。

第2-25页的表2-5是从$00000000到$FFFFFF。地图的许多区域是用户可编程的,并且建议的用途如表所示。

❏ 高速缓存抑制功能可在MMU中编程。

❏ 板载输入/输出空间必须标记为缓存抑制和在其页面表中序列化。

第2-26页的表2-6进一步定义了本地输入/输出的映射设备。

and the corresponding material kilogram will be automatically converted by PLC and imported into the system for application. The curve rate is obtained according to the weight of the test weight and the curve characteristics of the module (see the instruction description of the module curve rate for details).

PLC: the program adopts wplsoft2 35 ladder diagram software. It includes four main parts: system setting, analog quantity acquisition, automatic operation and manual operation. Scan the ladder diagram during operation, automatically jump and switch according to external instructions, and execute continuously.

Process control:

The console is equipped with manual / automatic transfer switch, emergency stop button, on-board quantity input button, automatic operation start button, system reset button, etc. For manual operation, each mechanism can be controlled independently.

On board quantity input button: each time you press it, the on-board quantity counter will automatically increase by one, and long press it to clear the data. You can also input the value directly through the touch screen. System reset button: clear the non power failure storage area register to return the system to standby state.

According to the construction requirements, input the corresponding data command through the man-machine interface, press the automatic operation start button, and the system will operate automatically and continuously. The operation process is divided into three stages: batching, feeding, mixing and concrete unloading.

1. Batching: the automatic operation start contact triggers the batching and metering of 4 aggregates, cement, chemicals and water. After the aggregate batching is completed, the system detects the hopper position. When the hopper is at the lower limit, the weighing belt is fed, and the weighing belt timer is started. When the time reaches, it will stop