WOODWARD 8280-423数字控制模块 PDF资料

1.产 品 资 料 介 绍:

中文资料:

WOODWARD 8280-423 数字控制模块 是一款广泛应用于发动机控制、涡轮机控制、发电机组控制以及其他工业自动化系统中的数字控制模块。它是Woodward公司生产的一部分,主要用于精确控制发动机、涡轮机以及其他机械设备的操作,确保其在预定工作条件下高效、稳定地运行。

主要特点和功能:

数字控制:

- 8280-423模块提供精确的数字化控制,能够处理各种输入信号,进行实时控制,并根据预设的控制策略对输出设备进行调整。它支持现代化的数字控制技术,具有高度的响应速度和控制精度。

多种输入和输出支持:

- 该模块支持多种类型的输入和输出,如模拟输入(4-20 mA、0-10 V)、开关量输入、数字输入等。对于输出,通常支持数字信号、模拟信号(4-20 mA 或 0-10V),以及继电器控制输出等。模块可以根据应用场景进行灵活配置。

高性能处理能力:

- 8280-423模块拥有强大的处理能力,能够实时处理大量的数据和信号,并基于控制算法调整输出设备的运行参数。它非常适合需要高实时性和高精度控制的应用,如发电机组控制、风力发电控制和其他工业过程控制系统。

通信接口:

- Woodward 8280-423 数字控制模块配备有多个工业通信接口,如 Modbus、Ethernet、CANopen 等标准协议,方便与其他设备(如PLC、HMI、SCADA 系统等)进行通信和数据交换。

自诊断功能:

- 模块具有内建的自诊断功能,能够实时监测自身的工作状态,包括电源、电气故障、信号异常等,并及时通过报警通知用户。这使得系统的维护更加简便,并能最大限度地减少因故障停机的时间。

高可靠性和抗干扰能力:

- 由于应用场合通常在工业环境中,Woodward 8280-423 控制模块设计时具有较强的抗干扰能力,能够在噪声较大、温度波动较大的环境中稳定工作。

灵活的参数配置和调节:

- 用户可以通过HMI(人机界面)或计算机上的软件工具来进行参数配置和调节,确保模块能够满足特定应用的需求。它通常配备有易于操作的界面,使得安装、配置和调试更加简便。

应用领域:

发电机控制:

- 8280-423 广泛应用于发电机组的控制系统中,能够对发电机的运行进行精确控制,保证其稳定性和高效性。它能够调节发电机的输出电压、频率和功率等参数,并对负载变化作出实时反应。

发动机控制:

- 在发动机控制系统中,Woodward 8280-423 作为关键组件,能够控制发动机的燃油喷射、点火时机、空气燃料比等重要参数,确保发动机在不同工况下的最佳性能。

涡轮机控制:

- 对于燃气涡轮机或蒸汽涡轮机,8280-423模块能够精确控制涡轮机的转速、负载以及其他关键性能指标。它能够根据输入的传感器数据进行实时调节,确保涡轮机的高效稳定运行。

风力发电:

- 在风力发电系统中,8280-423 控制模块用于优化风力涡轮机的运行,调节叶片角度、风速监测等,最大限度地提高发电效率。

工业过程控制:

- 该模块可应用于多个工业自动化领域,例如化工、石油、电力、矿山等,在过程控制中对设备运行状态进行实时监测和调节。

船舶与海洋设备:

- 在船舶及海洋设备中,8280-423 用于控制主机、辅助发动机、泵、阀等设备,确保设备的高效运行和系统的安全稳定。

技术规格(典型):

输入类型:

- 模拟输入(4-20 mA,0-10V等)

- 数字输入(开关量信号)

- 编码器输入(用于转速或位置监测)

输出类型:

- 模拟输出(4-20 mA 或 0-10 V)

- 继电器输出(用于启停控制)

- 数字输出(用于控制信号)

通信协议:

- Modbus RTU, Modbus TCP/IP, CANopen, Ethernet/IP 等常见工业协议

电源要求:

- 通常为24V DC(具体依应用而定)

工作温度范围:

- -40°C 到 +70°C,适应广泛的工业环境

尺寸与安装:

- 紧凑设计,通常支持DIN导轨安装,便于在控制柜中集成

诊断与报警功能:

- 内建自诊断与故障报警功能,确保设备运行时的监控与维护

英文资料:

WOODWARD 8280-423 digital control module is a widely used digital control module in engine control, turbine control, generator set control, and other industrial automation systems. It is a part of Woodward's production, mainly used for precise control of the operation of engines, turbines, and other mechanical equipment, ensuring their efficient and stable operation under predetermined working conditions.

Main features and functions:

Digital control:

The 8280-423 module provides precise digital control, capable of processing various input signals, performing real-time control, and adjusting output devices according to preset control strategies. It supports modern digital control technology, with high response speed and control accuracy.

Multiple input and output support:

This module supports multiple types of inputs and outputs, such as analog inputs (4-20 mA, 0-10 V), switch inputs, digital inputs, etc. For output, it usually supports digital signals, analog signals (4-20 mA or 0-10V), and relay controlled outputs. Modules can be flexibly configured according to application scenarios.

High performance processing capability:

The 8280-423 module has powerful processing capabilities, capable of real-time processing of large amounts of data and signals, and adjusting the operating parameters of output devices based on control algorithms. It is very suitable for applications that require high real-time and high-precision control, such as generator control, wind power control, and other industrial process control systems.

Communication interface:

The Woodward 8280-423 digital control module is equipped with multiple industrial communication interfaces, such as Modbus, Ethernet, CANopen and other standard protocols, to facilitate communication and data exchange with other devices (such as PLC, HMI, SCADA systems, etc.).

Self diagnostic function:

The module has built-in self diagnostic function, which can monitor its own working status in real time, including power supply, electrical faults, signal abnormalities, etc., and notify users in a timely manner through alarms. This makes system maintenance easier and minimizes downtime due to malfunctions.

High reliability and anti-interference ability:

Due to its typical application in industrial environments, the Woodward 8280-423 control module is designed with strong anti-interference capabilities and can operate stably in environments with high noise and temperature fluctuations.

Flexible parameter configuration and adjustment:

Users can configure and adjust parameters through HMI (Human Machine Interface) or software tools on the computer to ensure that the module meets the specific application requirements. It is usually equipped with an easy-to-use interface, making installation, configuration, and debugging easier.

Application areas:

Generator control:

8280-423 is widely used in the control system of generator sets, which can accurately control the operation of the generator, ensuring its stability and efficiency. It can adjust the output voltage, frequency, power and other parameters of the generator, and make real-time responses to load changes.

Engine control:

In the engine control system, Woodward 8280-423 serves as a key component that can control important parameters such as fuel injection, ignition timing, and air-fuel ratio to ensure optimal performance of the engine under different operating conditions.

Turbine control:

For gas or steam turbines, the 8280-423 module can precisely control the speed, load, and other key performance indicators of the turbine. It can make real-time adjustments based on input sensor data to ensure efficient and stable operation of the turbine.

Wind power generation:

In wind power generation systems, the 8280-423 control module is used to optimize the operation of wind turbines, adjust blade angles, wind speed monitoring, etc., and maximize power generation efficiency.

Industrial process control:

This module can be applied to multiple industrial automation fields, such as chemical, petroleum, power, mining, etc., to monitor and adjust the real-time operation status of equipment in process control.

Ships and marine equipment:

In ships and marine equipment, 8280-423 is used to control main engines, auxiliary engines, pumps, valves, and other equipment to ensure efficient operation of the equipment and safe and stable systems.

Technical specifications (typical):

Input type:

Analog input (4-20 mA, 0-10V, etc.)

Digital input (switch signal)

Encoder input (for speed or position monitoring)

Output type:

Analog output (4-20 mA or 0-10 V)

Relay output (for start stop control)

Digital output (for control signals)

Communication protocol:

Common industrial protocols such as Modbus RTU, Modbus TCP/IP, CANopen, Ethernet/IP, etc

Power requirements:

Usually 24V DC (depending on the application)

Working temperature range:

-40 ° C to+70 ° C, suitable for a wide range of industrial environments

Size and Installation:

Compact design, typically supporting DIN rail installation for easy integration in control cabinets

Diagnostic and alarm functions:

Built in self diagnosis and fault alarm functions ensure monitoring and maintenance of equipment during operation

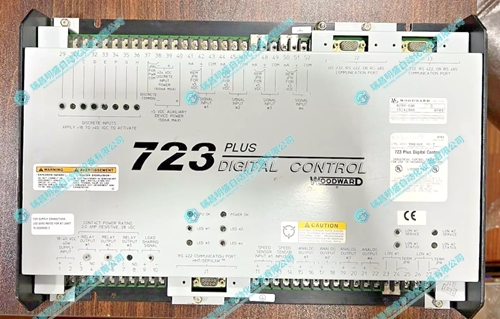

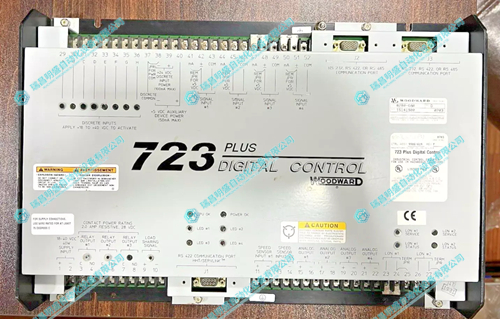

2.产 品 展 示

3.其他产品

4.其他英文产品

AMAT 0190-11415 Digital Input Module

GE D20 EME 10BASE-T Digital Control Modu

3BHE009681R0101 GVC750BE101 thyristor hi

5.更多库存型号

| PFRL101A | MC-TAIH62 | |

| PFEL113 | 6SC6000-0NA02 | MC-PDOY22 80363975-150 |

| PFEL111 | 6SC6140-0FE01 | MC-PD1X02 |

| PFEA113 | 6SC6500-0UC01 | MC-TAIL02 |

| PFEA112 | MC-TAIL12 | |

| PFEA111 | 6SC6120-0FE00 | MC-TAIH02 |

| PFEA101 | MC-TDODI3 |

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.