Brooks 001-7124-01机器人控制器板 PDF资料

1.产 品 资 料 介 绍:

中文资料:

Brooks 001-7124-01 机器人控制器板 是 Brooks Automation 提供的一款高性能控制器板,专为工业机器人系统设计,负责机器人各项运动控制、任务调度、数据处理及系统协调。作为机器人控制系统中的核心组件,它确保机器人能够精准执行任务,同时与其他系统和设备进行高效的协调。

产品特点:

- 精确运动控制:Brooks 001-7124-01 机器人控制器板能够精确控制机器人各关节的运动,支持高速、高精度的运动轨迹规划和实时反馈,确保机器人在复杂操作中的稳定性和精确性。

- 多通道输入输出:支持多种输入输出接口,包括数字和模拟信号输入、PWM输出、脉冲输出等,能够与传感器、执行器和其他设备进行高效的信号交换。

- 实时控制能力:内置高速处理器和专用的运动控制单元,能够在微秒级别响应外部信号变化,适应高速、实时的控制要求。

- 高级编程与调试功能:支持高级编程功能和调试工具,能够根据不同的应用需求进行定制化控制,同时提供便捷的编程接口,便于开发人员进行系统集成。

- 高可靠性:该控制器板采用工业级设计,具有较强的抗干扰能力和耐高温能力,适应各种严苛的工作环境,确保机器人系统的长期稳定运行。

- 通信与集成能力:兼容多种工业通信协议(如RS-485、Ethernet、CAN等),支持与其他设备和控制系统的无缝集成。

技术参数:

- 型号:Brooks 001-7124-01

- 输入/输出接口:

- 多通道数字和模拟信号输入输出。

- 支持脉冲控制输出,适用于电机驱动控制。

- 支持外部传感器和执行器的连接。

- 处理能力:集成高速处理器,支持多任务并行处理,能够实时响应控制信号。

- 编程接口:支持自定义的运动控制算法和任务调度,具备可编程的接口,便于与其他自动化系统集成。

- 工作温度范围:通常为-10°C至+60°C,适应各种工业环境。

- 电源要求:24V直流电源或其他常见工业电源。

- 通信协议:支持RS-485、CAN总线、Ethernet等多种工业标准协议。

- 保护机制:具备过热、过载保护等功能,确保系统运行安全。

应用领域:

- 工业机器人:广泛应用于各种类型的工业机器人系统中,如焊接机器人、装配机器人、搬运机器人等,负责精确控制机器人的运动轨迹、操作任务以及协调各个机械臂和执行器。

- 自动化生产线:用于自动化生产线的控制系统中,协同机器人与其他自动化设备(如传送带、机械臂等)协调工作,提高生产效率。

- 实验室自动化:在实验室自动化系统中,Brooks 001-7124-01 机器人控制器板可用于机器人操作的控制,例如自动样品处理、测试设备控制等。

- 精密装配与加工:用于精密装配和加工任务中,确保机器人能够高精度地执行任务,如微型元件组装、精准加工等。

- 物流自动化:用于物流系统中,如自动化仓储、搬运、包装等任务中的机器人控制。

英文资料:

The Brooks 001-7124-01 robot controller board is a high-performance controller board provided by Brooks Automation, designed specifically for industrial robot systems, responsible for robot motion control, task scheduling, data processing, and system coordination. As a core component in robot control systems, it ensures that robots can perform tasks accurately while efficiently coordinating with other systems and devices.

Product features:

Precise motion control: The Brooks 001-7124-01 robot controller board can accurately control the motion of each joint of the robot, supporting high-speed and high-precision motion trajectory planning and real-time feedback, ensuring the stability and accuracy of the robot in complex operations.

Multi channel input/output: Supports multiple input/output interfaces, including digital and analog signal input, PWM output, pulse output, etc., enabling efficient signal exchange with sensors, actuators, and other devices.

Real time control capability: Equipped with a built-in high-speed processor and dedicated motion control unit, it can respond to external signal changes at the microsecond level, adapting to high-speed and real-time control requirements.

Advanced programming and debugging functions: Supports advanced programming functions and debugging tools, can customize control according to different application requirements, and provides convenient programming interfaces for developers to integrate the system.

High reliability: The controller board adopts industrial grade design, with strong anti-interference ability and high temperature resistance, suitable for various harsh working environments, ensuring the long-term stable operation of the robot system.

Communication and integration capabilities: Compatible with multiple industrial communication protocols (such as RS-485, Ethernet, CAN, etc.), supporting seamless integration with other devices and control systems.

Technical parameters:

Model: Brooks 001-7124-01

Input/output interface:

Multi channel digital and analog signal input and output.

Supports pulse control output, suitable for motor drive control.

Support the connection of external sensors and actuators.

Processing capability: Integrated high-speed processor, supports multitasking parallel processing, and can respond to control signals in real time.

Programming Interface: Supports custom motion control algorithms and task scheduling, with programmable interfaces for easy integration with other automation systems.

Working temperature range: typically -10 ° C to+60 ° C, suitable for various industrial environments.

Power requirement: 24V DC power supply or other common industrial power supply.

Communication protocol: Supports various industrial standard protocols such as RS-485, CAN bus, Ethernet, etc.

Protection mechanism: It has functions such as overheating and overload protection to ensure the safe operation of the system.

Application areas:

Industrial robots: widely used in various types of industrial robot systems, such as welding robots, assembly robots, handling robots, etc., responsible for precise control of the robot's motion trajectory, operation tasks, and coordination of various robotic arms and actuators.

Automated production line: used in the control system of automated production lines, collaborative robots work in coordination with other automation equipment (such as conveyor belts, robotic arms, etc.) to improve production efficiency.

Laboratory Automation: In laboratory automation systems, the Brooks 001-7124-01 robot controller board can be used for controlling robot operations, such as automatic sample processing, testing equipment control, etc.

Precision assembly and machining: used in precision assembly and machining tasks to ensure that robots can perform tasks with high precision, such as micro component assembly, precision machining, etc.

Logistics automation: used for robot control in logistics systems, such as automated warehousing, handling, packaging, and other tasks.

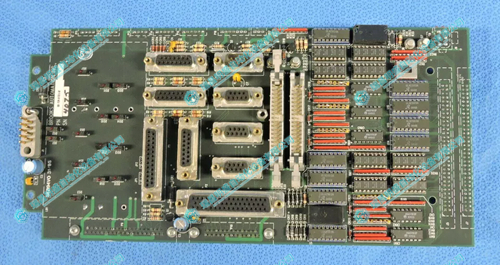

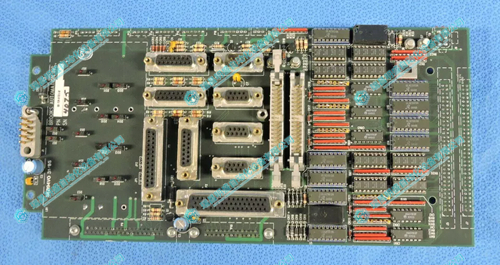

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA DSCA121 Robot Control Board

5.更多库存型号

| PMA42N-01100-00 | AMAT 0100-09001 | PFTL 101B-20.0KN |

| PMA42N-00100-00 | AMAT 0100-00611 | PFTL 301E-0.5 |

| PMA42M-10100-00 | AMAT 0100-02797 | PFTL 301E-0.1 |

| PMA42M-01100-00 | AMAT 0100-14005 | PFTL 101BE-10.0KN |

| PMA42M-00100-00 | AMAT 0100-35082 | PFEA112-IP20 3BSE030369R0020 |

| PMA24K-1050B-02 | AMAT 0100-90139 | PFTL 101A-1.0KN |

| PMA24D-10100-00 | AMAT 0100-00642 | PFTL 301E-1.0KN |

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.co