Rexroth SE352 双重控制器 PDF资料

1.产 品 资 料 介 绍:

中文资料:

Rexroth SE352 是博世力士乐(Bosch Rexroth)的一款双重控制器,专为复杂的工业自动化系统设计。该控制器具有双通道控制功能,能够同时处理两个独立的控制任务,从而在单一设备中实现更高的控制能力和灵活性。以下是其主要特点和应用领域:

主要特点:

双通道控制: SE352 控制器可以同时管理两个独立的控制任务,减少了对额外控制设备的需求,优化了系统结构。

高精度与高响应性: 提供高精度的位置、速度和扭矩控制,适合需要快速响应的应用场景。

模块化设计: 允许与其他Rexroth控制设备集成,便于扩展和升级,满足不同应用需求。

通信接口: 支持多种工业标准通信协议,如EtherCAT、Profibus、CANopen等,方便与其他设备进行集成。

用户友好: 配备直观的用户界面和编程工具,使设置和操作更加简单。

主要应用领域:

数控机床

- 应用: 用于复杂机床系统中控制多个轴的同步动作,如车削、铣削和磨削操作。

- 优势: 通过双通道控制实现多轴同步,提高加工精度和效率。

包装机械

- 应用: 在包装流水线中控制不同工位的机械动作,如灌装、封口、贴标等。

- 优势: 实现多任务处理,提高包装线的整体效率。

印刷和纸加工设备

- 应用: 控制印刷和纸张处理设备的多个运动部件,如印刷头和传送系统。

- 优势: 提供同步控制,确保印刷和纸张加工过程的精确性。

自动化生产线

- 应用: 用于自动化生产线中的多工位控制,管理各工序之间的协调动作。

- 优势: 减少设备间的通信延迟,提高生产线的协调性和效率。

工业机器人

- 应用: 控制工业机器人多个关节的协调动作,支持复杂的自动化操作任务。

- 优势: 通过双重控制提高机器人动作的协调性和精度。

测试和测量设备

- 应用: 在需要同时测量多个参数的设备中进行同步控制,如振动测试、环境模拟测试等。

- 优势: 提供精确的同步控制,确保测试结果的可靠性。

汽车制造

- 应用: 在汽车生产线中控制多个加工或装配工位的同步动作,如焊接、喷涂和装配。

- 优势: 实现多工位同步,提高生产效率和产品一致性。

电子产品制造

- 应用: 控制电子产品生产中的多道工序,如贴片、焊接和检测。

- 优势: 提供高精度控制,适应精密制造的要求。

Rexroth SE352 双重控制器在多任务处理和复杂工业应用中具有显著的优势,特别是在需要高精度、高响应性的环境中,能够显著提高系统的控制能力和整体效率。

英文资料:

The Rexroth SE352 is a dual controller from Bosch Rexroth, designed specifically for complex industrial automation systems. This controller has dual channel control function, which can simultaneously handle two independent control tasks, thereby achieving higher control capability and flexibility in a single device. The following are its main characteristics and application areas:

Main features:

Dual channel control: The SE352 controller can manage two independent control tasks simultaneously, reducing the need for additional control devices and optimizing the system structure.

High precision and high responsiveness: Provides high-precision position, speed, and torque control, suitable for application scenarios that require rapid response.

Modular design: allows integration with other Rexroth control devices for easy expansion and upgrade, meeting different application requirements.

Communication interface: Supports multiple industrial standard communication protocols, such as EtherCAT, Profibus, CANopen, etc., making it easy to integrate with other devices.

User friendly: Equipped with an intuitive user interface and programming tools, making setup and operation easier.

Main application areas:

numerical control machine

Application: Used for controlling synchronous actions of multiple axes in complex machine tool systems, such as turning, milling, and grinding operations.

Advantage: Multi axis synchronization is achieved through dual channel control, improving machining accuracy and efficiency.

Packaging Machinery

Application: Control the mechanical actions of different workstations in the packaging assembly line, such as filling, sealing, labeling, etc.

Advantage: Achieve multitasking and improve the overall efficiency of the packaging line.

Printing and paper processing equipment

Application: Control multiple moving parts of printing and paper processing equipment, such as print heads and conveyor systems.

Advantage: Provides synchronous control to ensure the accuracy of printing and paper processing processes.

automatic production line

Application: Used for multi station control in automated production lines, managing coordinated actions between various processes.

Advantages: Reduce communication latency between devices, improve coordination and efficiency of production lines.

Industrial robot

Application: Control the coordinated movements of multiple joints in industrial robots and support complex automation tasks.

Advantage: Improve the coordination and accuracy of robot actions through dual control.

Testing and measuring equipment

Application: Synchronize control in devices that require simultaneous measurement of multiple parameters, such as vibration testing, environmental simulation testing, etc.

Advantage: Provides precise synchronization control to ensure the reliability of test results.

Automobile manufacturing

Application: Control the synchronous actions of multiple processing or assembly stations in the automotive production line, such as welding, spraying, and assembly.

Advantages: Achieving multi station synchronization, improving production efficiency and product consistency.

Electronic product manufacturing

Application: Control multiple processes in electronic product production, such as SMT, soldering, and testing.

Advantage: Provides high-precision control to meet the requirements of precision manufacturing.

The Rexroth SE352 dual controller has significant advantages in multitasking and complex industrial applications, especially in environments that require high precision and responsiveness, which can significantly improve the system's control capability and overall efficiency.

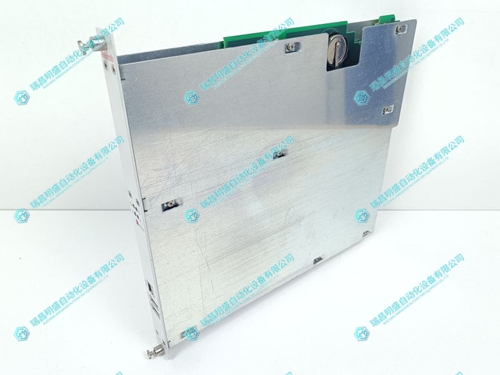

2.产 品 展 示

3.其他产品

1MRK002133-ABr02 PC Ethernet adapter

3BHE039203R0101 Processor module

3BHE039724R0C3D high-performance control system

5.更多库存型号

| PMB31B-20114-03 | AMAT 0100-00015 | PFTL301E |

| PMB31B-00216-00 | AMAT 0100-03536 | PFCL301E |

| PMB33E-00201-03 | AMAT 0100-35067 | PFRL101A 0.5KN 3BSE023314R0003 |

| PMB33C-00100-00 | AMAT 0100-01415 | PFRL101A 1.0KN 3BSE023317R0002 |

| PMB33C-10201-03 | AMAT 0020-03509C | PFRL101B 1.0KN 3BSE023315R0004 |

| PMB33E-20101-01 | AMAT 0100-09299 | PFRL101B 0.5KN |

| PMB33C-10214-03 | AMAT 0100-90863 | PFRL101C 0.5KN 3BSE023316R0502 |

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.com