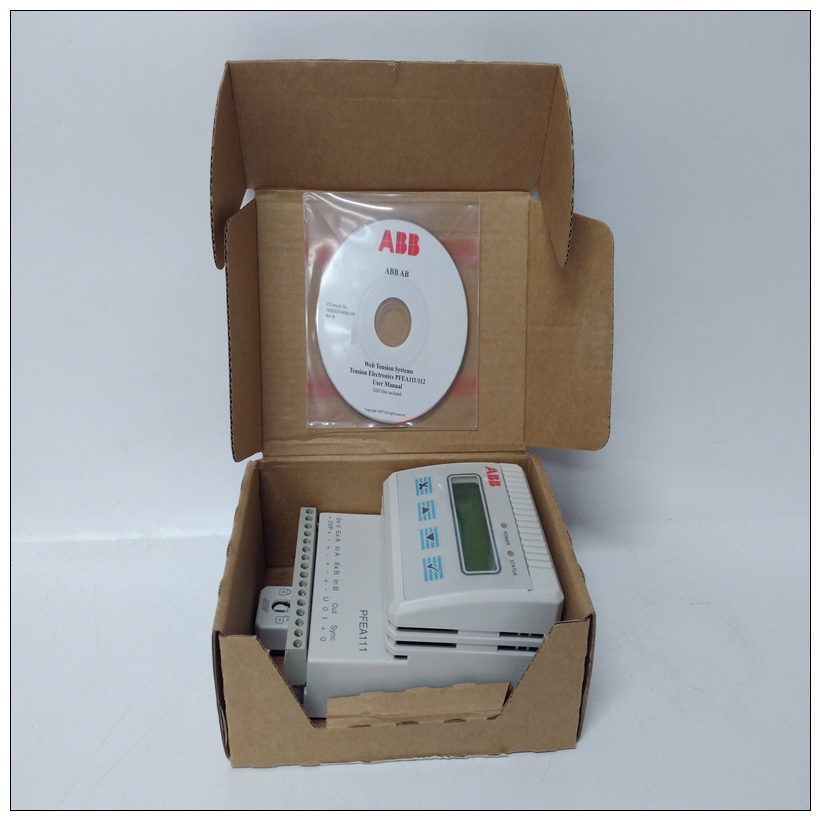

PFEA111-20控制器,PFEA111-20使用过程

HSS模块提供对节气门位置的控制涡轮机速度控制系统。MFP模块将数据发送到HSS模块,用于指导液压执行器的控制(通过伺服阀或I/H转换器)。通过发送位置根据HSS模块的要求,MFP模块启动更改涡轮转速。位置需求通过输入/输出传递扩展器总线至HSS模块。车载微处理器

读取需求并将其加载到数模转换(D/a)中转换器。产生的模拟值驱动伺服阀。

PFEA111-20控制器伺服阀将液压油加载到双离合器的一侧动作液压执行器。当液压执行器打开或关闭节流阀,涡轮转速改变。如果液压执行器由I/H转换器驱动,然后HSS模块将MFP模块发送的信号缩放到4至20毫安信号或20至160毫安信号和绕过PID控制器电路。这是4到20毫安信号线性驱动I/H转换器加载液压油至双作用执行器的一侧。

MFP模块在其配置中需要功能代码55或150,以指导IMHSS03模块的操作。功能代码55定义了模块地址、操作模式(校准或正常)、校准周期时间并存储校准数据。十个输出块包括执行器位置,数模转换器输出、伺服阀线圈输出电流以及模块和过程的状态输出设备

The HSS module provides control of throttle valve position in a

turbine speed control system. The MFP module sends data to

the HSS module, which directs the control of a hydraulic actu�

ator (via a servo valve or I/H converter). By sending a position

demand to the HSS module, the MFP module initiates a change

in turbine speed. The position demand travels over the I/O

expander bus to the HSS module. An on-board microprocessor

reads the demand and loads it into a digital-to-analog (D/A)

converter. The resulting analog value drives the servo valve.

The servo valve loads hydraulic fluid to one side of a double

acting hydraulic actuator. As the hydraulic actuator opens or

closes the throttle valve, the turbine speed changes. If the

hydraulic actuator is being driven by an I/H converter, then

the HSS module scales the signal sent by the MFP module to a

four to 20 milliamp signal or 20 to 160 milliamp signal and the

PID controller circuitry is bypassed. This four to 20 milliamp

signal linearly drives the I/H converter to load hydraulic fluid

to one side of the double acting actuator.

The MFP module requires function code 55 or 150 in its config�

uration to direct the operation of the IMHSS03 module. Func�

tion code 55 defines the module address, mode of operation

(calibration or normal), calibration cycle time and stores cali�

bration data. The ten output blocks include actuator position,

digital-to-analog converter output, servo valve coil output cur�

rent, and status outputs for the module and process

equipment.