ASEA DSQC223机器人控制板

1.产 品 资 料 介 绍:

中文资料:

ASEA DSQC223 机器人控制板是用于 ASEA(现在 ABB)机器人系统的一个重要组件,主要负责机器人控制和管理。以下是 DSQC223 机器人控制板的主要特点和应用领域:

ASEA DSQC223 机器人控制板的主要特点

控制功能:

- 运动控制:负责机器人臂的运动控制,包括位置、速度和加速度的调节,以实现精确的动作和操作。

- 路径规划:支持复杂的路径规划和轨迹控制,确保机器人按照预定的路径执行任务。

高性能处理:

- 实时处理:具备实时数据处理能力,能够快速响应机器人系统中的变化,保证控制的准确性和系统的稳定性。

- 高计算能力:内置高性能处理器,能够处理复杂的控制算法和计算任务。

接口和连接:

- 多种接口:提供多种输入输出接口,支持与传感器、执行器和其他控制设备的连接。

- 通信协议:支持多种通信协议,用于与其他系统或设备进行数据交换和控制。

系统集成:

- 兼容性:能够与 ASEA 及其他品牌的机器人系统和自动化设备兼容,方便集成到现有的系统中。

- 模块化设计:设计为模块化,便于安装、维护和更换,提高了系统的灵活性和可靠性。

诊断和监控:

- 故障诊断:具备故障诊断功能,能够实时监测系统状态并提供故障信息,便于维护和修复。

- 实时监控:支持实时监控机器人系统的运行状态,提供数据采集和性能分析功能。

用户友好:

- 操作界面:设计有用户友好的操作界面,便于配置和调整控制参数,简化操作流程。

应用领域

1. 工业自动化

- 制造业:用于制造业中的各种自动化任务,如装配、焊接、喷涂等,通过精确控制机器人动作提高生产效率和产品质量。

- 装配线:在自动化装配线上,控制机器人完成复杂的装配任务,提高装配精度和速度。

2. 机器人系统

- 运动控制:在机器人系统中,DSQC223 负责控制机器人的运动部件,实现高精度的位置和速度控制。

- 复杂任务:支持执行复杂的机器人任务,如多轴协调运动、复杂路径跟踪等。

3. 电子工业

- 测试和组装:用于电子产品的测试和组装过程,控制机器人进行高精度的操作和测试。

- 产品搬运:在电子产品生产线中,控制机器人进行产品搬运和分类,提高生产效率。

4. 制造业

- 加工设备:在数控机床和其他加工设备中,DSQC223 控制板用于机器人控制,实现精确的加工操作。

- 材料处理:在制造过程中,控制机器人进行材料处理和搬运,支持高效的生产流程。

5. 医疗和实验室

- 自动化实验:在医疗和实验室中,控制机器人进行自动化实验和样本处理,提高实验效率和准确性。

- 装配和搬运:用于医疗设备的装配和搬运,提供高精度的操作和控制。

综述

ASEA DSQC223 机器人控制板在各种工业自动化和机器人系统中发挥着核心作用,其高性能的处理能力、多种接口和通信协议、以及先进的控制功能,使其能够满足复杂的机器人控制需求。

英文资料:

The ASEA DSQC223 robot control board is an important component used in ASEA (now ABB) robot systems, mainly responsible for robot control and management. The following are the main features and application areas of the DSQC223 robot control board:

Main features of ASEA DSQC223 robot control board

Control function:

Motion Control: Responsible for the motion control of the robot arm, including the adjustment of position, velocity, and acceleration, to achieve precise actions and operations.

Path planning: Supports complex path planning and trajectory control to ensure that robots execute tasks according to predetermined paths.

High performance processing:

Real time processing: With real-time data processing capabilities, it can quickly respond to changes in the robot system, ensuring control accuracy and system stability.

High computing power: Built in high-performance processor capable of handling complex control algorithms and computational tasks.

Interface and Connection:

Multiple interfaces: Provides multiple input and output interfaces, supporting connections with sensors, actuators, and other control devices.

Communication Protocol: Supports multiple communication protocols for data exchange and control with other systems or devices.

System integration:

Compatibility: It is compatible with ASEA and other brands of robot systems and automation equipment, making it easy to integrate into existing systems.

Modular design: Designed as modular, it facilitates installation, maintenance, and replacement, improving the flexibility and reliability of the system.

Diagnosis and monitoring:

Fault diagnosis: With fault diagnosis function, it can monitor the system status in real time and provide fault information for easy maintenance and repair.

Real time monitoring: Supports real-time monitoring of the operating status of robot systems, providing data collection and performance analysis functions.

User friendly:

Operation interface: Designed with a user-friendly interface, it is easy to configure and adjust control parameters, simplifying the operation process.

application area

1. Industrial automation

Manufacturing: Used for various automation tasks in manufacturing, such as assembly, welding, spraying, etc., to improve production efficiency and product quality through precise control of robot movements.

Assembly line: On an automated assembly line, control robots to complete complex assembly tasks, improving assembly accuracy and speed.

2. Robot system

Motion control: In the robot system, DSQC223 is responsible for controlling the moving parts of the robot to achieve high-precision position and velocity control.

Complex tasks: Support the execution of complex robot tasks, such as multi axis coordinated motion, complex path tracking, etc.

3. Electronic industry

Testing and Assembly: Used for the testing and assembly process of electronic products, controlling robots for high-precision operation and testing.

Product handling: In electronic product production lines, controlling robots for product handling and classification improves production efficiency.

4. Manufacturing industry

Processing equipment: In CNC machine tools and other processing equipment, the DSQC223 control board is used for robot control to achieve precise processing operations.

Material handling: During the manufacturing process, control robots to handle and transport materials, supporting efficient production processes.

5. Medical and laboratory

Automated experiments: In medical and laboratory settings, controlling robots for automated experiments and sample processing improves experimental efficiency and accuracy.

Assembly and Handling: Used for the assembly and handling of medical equipment, providing high-precision operation and control.

overview

The ASEA DSQC223 robot control board plays a core role in various industrial automation and robot systems. Its high-performance processing capabilities, multiple interfaces and communication protocols, and advanced control functions enable it to meet complex robot control requirements.

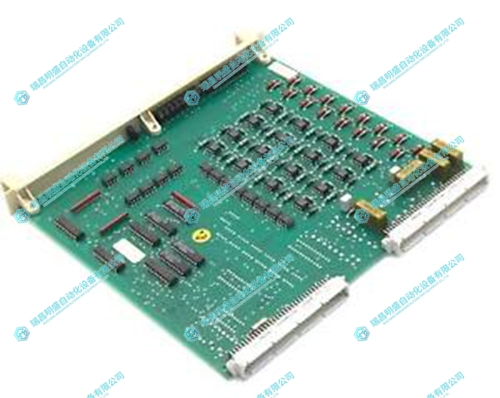

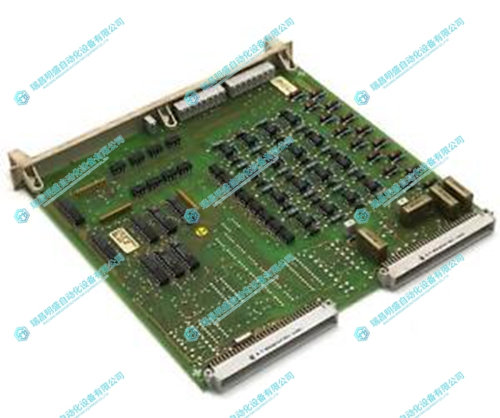

2.产 品 展 示

3.其他产品

AMAT 0190-66253 Communication Module

RADISYS 061-05927-0031 adapter module

Radisys EPC-3307 processor board

5.更多库存型号

| 5220 | HG96A603 | INICTO3A |

| 5410-008 | SSM-28-F | INIIT03 |

| 6410-001-N-H-K | SS400-10084 | INLIM03 |

| 6410-020-N-N-N | HP56B607 | INMMP11 |

| 6410-006-N-N-N | S9MS11A1A0A | INNIS01 |

| 6410-001-C-H-N | STD0002 | INNIS11 |

| 6410-005 | HZ40A6R521 | IMMFP02 |

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.com