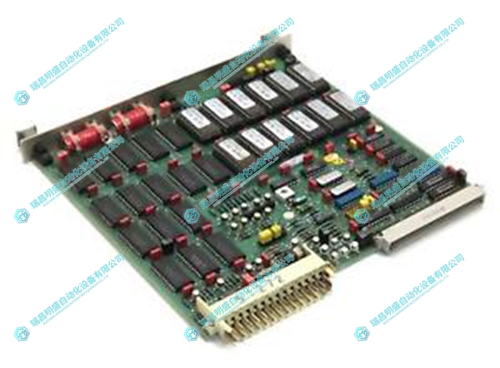

ASEA 2668 180-179机器人控制器模块

1.产 品 资 料 介 绍:

中文资料:

ASEA 2668 180-179机器人控制器模块是一种用于工业机器人控制的高性能组件,主要应用于各种自动化系统和过程控制环境中。以下是该模块的应用领域、主要功能和技术特点的详细介绍:

应用领域

工业自动化:

- 用于自动化生产线中的机器人控制,管理和协调机器人在装配、焊接、搬运、喷涂等任务中的动作,提高生产效率和一致性。

汽车制造:

- 在汽车制造过程中控制机器人进行焊接、喷涂、装配等工艺,提升生产速度、质量和精度。

电子制造:

- 在电子产品制造中,控制机器人进行精密操作,如组件组装、测试和包装,确保高质量的生产标准。

食品和饮料:

- 应用于食品和饮料行业的包装、处理和分拣过程,提高生产效率和卫生标准。

医疗设备制造:

- 在医疗设备生产中,控制机器人进行精密组装和加工,确保产品质量和生产效率。

物流与仓储:

- 用于自动化仓储系统中的机器人控制,管理物料搬运、分拣和堆垛,提高物流效率和准确性。

机械制造:

- 在机械制造中,控制机器人进行数控加工、组装和测试,提升制造精度和生产效率。

主要功能

运动控制:

- 提供高精度的运动控制,支持多轴联动和复杂轨迹的执行,适应各种工业应用中的运动需求。

实时控制:

- 实现对机器人的实时控制和调度,确保操作的及时性和准确性。

程序执行:

- 支持多种编程语言和控制程序,允许用户定义和执行复杂的机器人任务和操作序列。

数据通信:

- 支持与其他控制系统和设备的通信,确保数据的实时传输和系统的协调工作,支持多种通信协议如现场总线和工业以太网。

故障诊断与保护:

- 提供故障诊断和报警功能,实时监控系统状态,预防和处理异常情况,确保系统的安全稳定运行。

技术特点

高可靠性:

- 设计符合工业级标准,具备高抗干扰能力和耐用性,能够在恶劣环境下稳定运行。

高精度:

- 提供高精度的运动控制和信号处理,确保机器人操作的精确性和一致性,适用于高精度控制任务。

模块化设计:

- 采用模块化设计,方便系统集成和扩展,可以根据实际需求进行灵活调整和升级。

兼容性:

- 具有良好的兼容性,能够与多种传感器、执行器和其他控制系统集成,适应不同的工业控制环境。

用户友好:

- 设计简洁,易于安装、配置和操作,配备友好的用户界面和编程工具,减少培训和维护成本。

总结

ASEA 2668 180-179机器人控制器模块在工业自动化和机器人控制系统中扮演着关键角色。它广泛应用于需要高效、精确控制和数据处理的领域,其高可靠性、高精度和模块化设计使其成为工业控制系统的理想选择,有效提升了生产效率、产品质量和系统的自动化水平。

英文资料:

ASEA 2668 180-179 Robot Controller Module is a high-performance component used for industrial robot control, mainly applied in various automation systems and process control environments. The following is a detailed introduction to the application areas, main functions, and technical features of this module:

application area

Industrial automation:

Used for robot control in automated production lines, managing and coordinating the actions of robots in tasks such as assembly, welding, handling, spraying, etc., to improve production efficiency and consistency.

Automobile manufacturing:

Control robots to perform welding, spraying, assembly and other processes in the automotive manufacturing process to improve production speed, quality and accuracy.

Electronic manufacturing:

In electronic product manufacturing, controlling robots for precise operations such as component assembly, testing, and packaging ensures high-quality production standards.

Food and beverages:

Applied in the packaging, processing, and sorting processes of the food and beverage industry to improve production efficiency and hygiene standards.

Medical equipment manufacturing:

In the production of medical equipment, controlling robots for precision assembly and processing ensures product quality and production efficiency.

Logistics and Warehousing:

Used for robot control in automated warehousing systems, managing material handling, sorting, and stacking to improve logistics efficiency and accuracy.

Mechanical manufacturing:

In mechanical manufacturing, controlling robots for CNC machining, assembly, and testing improves manufacturing accuracy and production efficiency.

major function

Motion control:

Provide high-precision motion control, support multi axis linkage and complex trajectory execution, and adapt to the motion requirements in various industrial applications.

Real time control:

Realize real-time control and scheduling of robots to ensure timely and accurate operations.

Program execution:

Supports multiple programming languages and control programs, allowing users to define and execute complex robot tasks and operation sequences.

Data communication:

Support communication with other control systems and devices to ensure real-time data transmission and system coordination, and support multiple communication protocols such as fieldbus and industrial Ethernet.

Fault diagnosis and protection:

Provide fault diagnosis and alarm functions, monitor system status in real-time, prevent and handle abnormal situations, and ensure the safe and stable operation of the system.

Technical features

High reliability:

Designed to meet industrial standards, it has high anti-interference ability and durability, and can operate stably in harsh environments.

high-precision:

Provide high-precision motion control and signal processing to ensure the accuracy and consistency of robot operations, suitable for high-precision control tasks.

Modular design:

Adopting modular design, it facilitates system integration and expansion, and can be flexibly adjusted and upgraded according to actual needs.

compatibility:

It has good compatibility and can be integrated with various sensors, actuators, and other control systems to adapt to different industrial control environments.

User friendly:

The design is simple, easy to install, configure, and operate, equipped with a user-friendly interface and programming tools, reducing training and maintenance costs.

summary

The ASEA 2668 180-179 robot controller module plays a critical role in industrial automation and robot control systems. It is widely used in fields that require efficient, precise control and data processing. Its high reliability, high precision, and modular design make it an ideal choice for industrial control systems, effectively improving production efficiency, product quality, and system automation level.

2.产 品 展 示

3.其他产品

RADISYS 061-05927-0031 adapter module

Radisys EPC-3307 processor board

GE VMIVME-017807-414001 直流信号输出模块

| UR6EV | CACR-PR01AE4ESY6 | 23158-100 |

| UR8LH | CACR-SK300AAB, | 0660-01847 |

| UR6UH | CACR-HR10BB | EPC-200A |

| UR6AV | CACR-SR10BZ1SSY367 | 61-0476-20 |

| UR8HH | CACR-IR44SFB | 97-9045-01 |

| UR8AH | CACR-SR07BE12M | EPC-9 |

| UR6DH | CACR-SR15BY1SSY48E | 060-00867-0002 |

| UR6CH | CACR-JU084ADABY500AA | EPC-3305 |

| UR9EV | CACR-JU051D2A | RB945G |

| UR9AH | CACR-SR20BE12G-E, | EPC-8A |

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.com