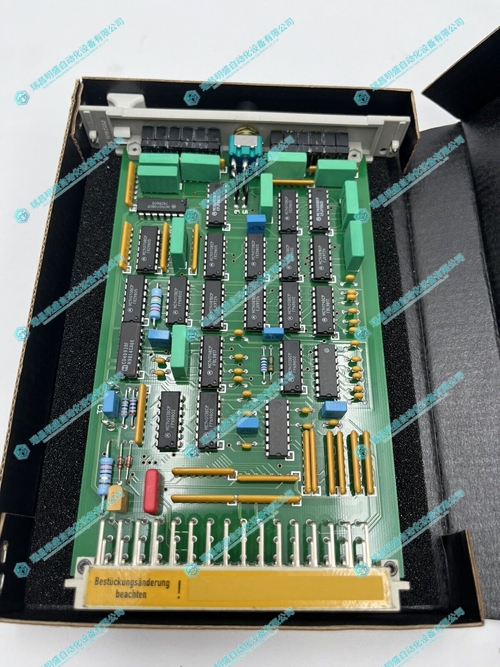

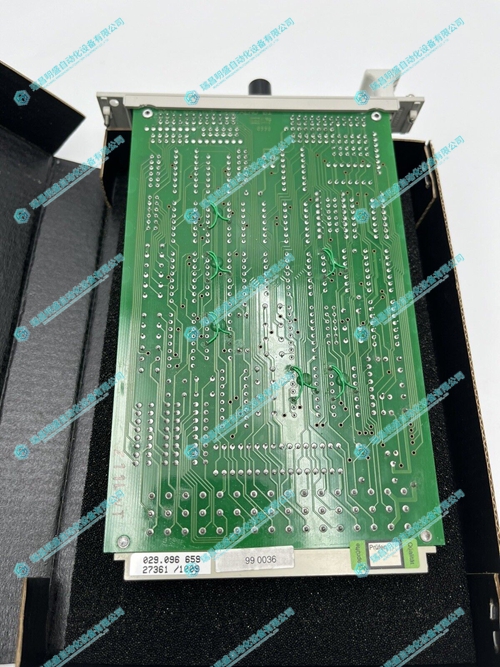

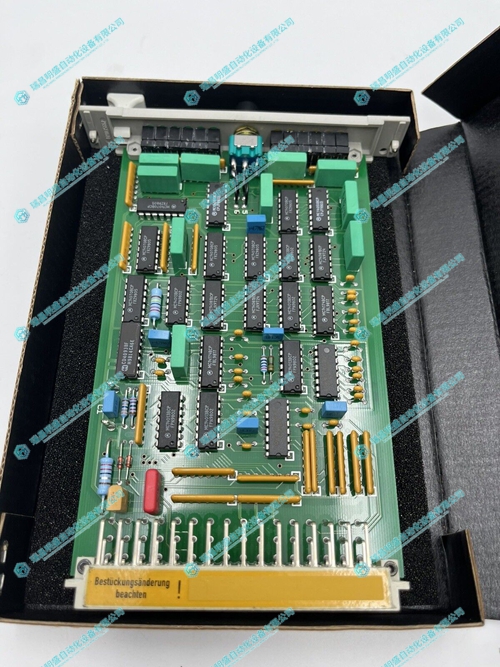

Alstom 029.096 659 27361接口模块

1.产 品 资 料 介 绍:

中文资料:

Alstom 029.096 659 27361接口模块是一种用于工业自动化和控制系统的设备,旨在为各种设备和系统提供通信接口。接口模块在自动化系统中起着关键作用,确保不同设备之间的数据传输和通信顺畅。

主要特点:

- 多种接口类型:支持多种通信接口,如串行接口、并行接口、以太网接口等,适应不同的连接需求。

- 高可靠性:设计坚固耐用,能够在恶劣的工业环境中长期稳定运行。

- 高速数据传输:支持高速数据传输,确保系统内各设备之间的数据通信效率高。

- 灵活配置:支持灵活的配置和扩展,能够根据具体应用需求进行定制。

- 兼容性强:兼容多种工业通信协议,确保与不同厂商设备的互操作性。

应用领域:

- 工业自动化:

- 在制造业、加工工业中,用于连接和控制生产线上的各种设备和传感器,确保生产过程的自动化和优化。

- 电力系统:

- 在变电站和配电系统中,用于连接和监控各种电力设备,实现数据采集和远程控制。

- 交通运输:

- 在铁路信号系统、交通管理系统中,用于连接和控制交通信号设备、道岔和其他关键设备。

- 楼宇自动化:

- 在智能楼宇系统中,用于连接和控制空调、照明、安全监控等系统,实现集中管理和控制。

- 能源管理:

- 在能源管理系统中,用于连接和监控发电设备、储能设备和配电设备,实现能源的优化管理和控制。

具体功能:

- 数据通信:通过多种接口实现设备之间的数据通信,确保数据的准确传输。

- 协议转换:支持多种工业通信协议,能够在不同协议之间进行转换,确保系统兼容性。

- 远程监控和管理:通过网络接口,实现对远程设备的监控和管理,便于集中控制和维护。

- 数据采集和处理:从连接的设备中采集数据,并进行必要的处理和分析,提供实时的系统状态和运行信息。

- 系统集成:与PLC、DCS等控制系统集成,实现复杂控制系统的统一管理和协调运行。

使用注意事项:

- 正确安装:按照设备说明书正确安装接口模块,确保连接牢固,避免松动和接触不良。

- 定期维护:定期检查接口模块的工作状态,清洁设备,检查接口连接,确保设备正常运行。

- 环境要求:确保接口模块的安装环境符合其工作要求,避免高温、潮湿、粉尘等对设备的影响。

- 安全防护:采取必要的电气安全措施,防止电击和短路等安全隐患。

- 故障处理:及时处理运行中出现的故障,避免对系统和设备造成进一步损害。

英文资料:

Alstom 029.096 659 27361 interface module is a device used in industrial automation and control systems, designed to provide communication interfaces for various devices and systems. Interface modules play a crucial role in automation systems, ensuring smooth data transmission and communication between different devices.

Main features:

Multiple interface types: Supports multiple communication interfaces, such as serial interface, parallel interface, Ethernet interface, etc., to meet different connection requirements.

High reliability: Designed to be sturdy and durable, capable of long-term stable operation in harsh industrial environments.

High speed data transmission: Supports high-speed data transmission to ensure high data communication efficiency between devices within the system.

Flexible configuration: Supports flexible configuration and expansion, and can be customized according to specific application needs.

Strong compatibility: Compatible with multiple industrial communication protocols to ensure interoperability with devices from different manufacturers.

Application areas:

Industrial automation:

In manufacturing and processing industries, it is used to connect and control various equipment and sensors on the production line, ensuring the automation and optimization of the production process.

Power system:

In substations and distribution systems, it is used to connect and monitor various power equipment, achieve data collection and remote control.

Transportation:

In railway signal systems and traffic management systems, it is used to connect and control traffic signal equipment, turnouts, and other critical devices.

Building automation:

In intelligent building systems, it is used to connect and control systems such as air conditioning, lighting, and security monitoring, achieving centralized management and control.

Energy Management:

In energy management systems, it is used to connect and monitor power generation equipment, energy storage equipment, and distribution equipment to achieve optimized management and control of energy.

Specific functions:

Data communication: Implement data communication between devices through multiple interfaces to ensure accurate transmission of data.

Protocol conversion: Supports multiple industrial communication protocols and can convert between different protocols to ensure system compatibility.

Remote monitoring and management: Through network interfaces, remote devices can be monitored and managed for centralized control and maintenance.

Data collection and processing: Collect data from connected devices, perform necessary processing and analysis, and provide real-time system status and operational information.

System integration: Integrate with control systems such as PLC and DCS to achieve unified management and coordinated operation of complex control systems.

Precautions for use:

Correct installation: Install the interface module correctly according to the equipment manual, ensuring a secure connection and avoiding looseness and poor contact.

Regular maintenance: Regularly check the working status of the interface module, clean the equipment, check the interface connection, and ensure the normal operation of the equipment.

Environmental requirements: Ensure that the installation environment of the interface module meets its working requirements and avoids the impact of high temperature, humidity, dust, etc. on the equipment.

Safety protection: Take necessary electrical safety measures to prevent safety hazards such as electric shock and short circuit.

Fault handling: Timely handle faults that occur during operation to avoid further damage to the system and equipment.

2.产 品 展 示

3.其他产品

AMAT 0190-11415 Digital Input Module

GE D20 EME 10BASE-T Digital Control Modu

KOLLMORGEN S70602-PBNANA 伺服驱动控制器

ABB UFC760BE01 3BHB007030R0001 可编程控制器

| PMB33C-10100-02 | NIDI01 | PMB33F-20101-01 |

| PMB33E-20116-00 | NIMF01 | PMB33F-20114-03 |

| PMB31D-00101-02 | NIMF02 | PMB33F-20114-02 |

| PMB31B-00201-03 | NIMP01 | PMB33F-20214-00 |

| PMB31B-10214-00 | NIRL03 | M21NRXA-JDN-NS-00 |

| PMB31B-10116-03 | NKAS11 | M22NRXB-LNN-NS-00 |

| PMB33C-00214-03 | NKLS010 | M21NRXA-LNN-NS-00 |

| PMB33E-00214-03 | NKLS020 | M21NRXB-LSS-NS-03 |

| PMB31D-20116-01 | NKLS110 | M22NRFA-LNF-NS-02 |

| PMB31D-00101-01 | NKLS111 | M21NRXE-LDN-NS-00 |

| PMB33E-10201-00 | NKLS112 | M21NSXA-LDN-HD-02 |

本篇文章出自瑞昌明盛自动化设备有限公司官网,转载请附上此链接:http://www.jiangxidcs.com