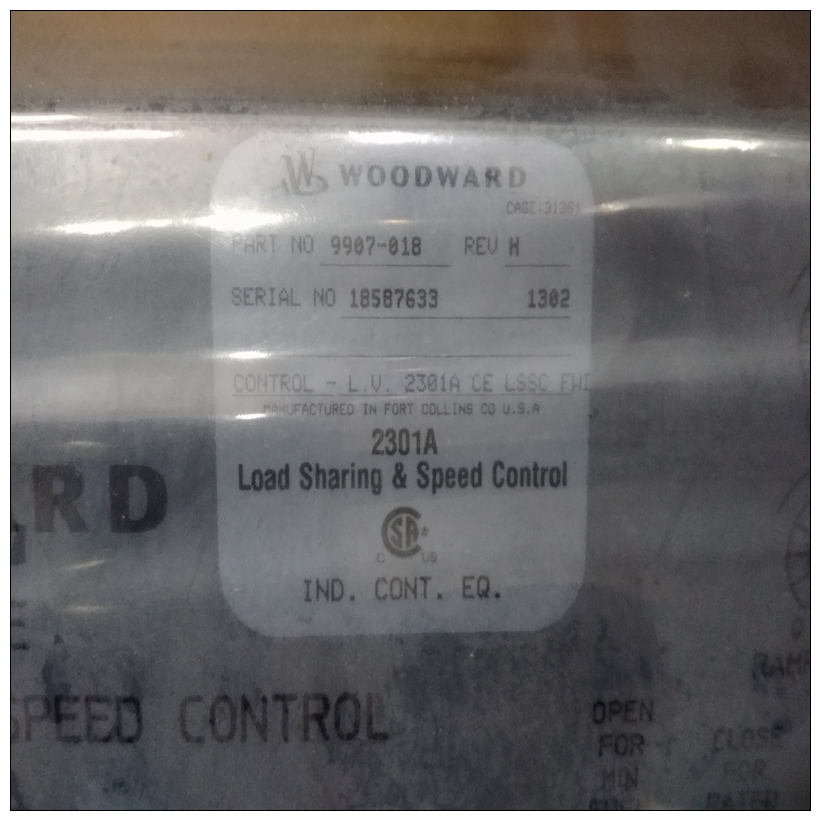

WOODWARD 9907-018调速器,9907-018使用配置手册

将控制器板放回主板上,并用四个螺钉将其固定。现在原始传感器信号位于连接条上。

安装显示器前,检查插槽接线。

2、将A6110显示器推入准备好的插槽,轻轻将其压入插头连接器。

3、用手拧紧前面板上的两个固定螺钉,以固定显示器。

任何其他信息,例如屏蔽和接地、监视器的配置等,都可以在“轴振动监视器A6110”的使用方向上找到,1.6技术数据

WOODWARD 9907-018调速器只有包含公差和极限值的信息才被视为绑定数据。数据无公差或误差限值仅供参考。我们保留进行技术变化− 尤其是软件。

如果没有其他信息,则以下所有信息均适用于通道1和通道2明确规定。

1.6.1信号调节通道1和通道2的两个独立信号输入,具有非耦合信号调节。

测量值输入差分电压放大输入,非−无功,开路−电路和短路−电路验证。

通道1 z8:SENS1H(+);z10:传感器1L(− 信号)

通道2 d8:SENS2H(+);d10:传感器2L(− 信号)

输入标称范围−1,0 ... −22.16伏限制范围0。。。−30伏直流电

输入电阻>100 kΩ

Place the controller board back on the main board and secure it with the four screws. Now,

the raw sensor signal is on the connection strip.

Installation

1. Check the slot wiring prior to installing the monitor.

2. Push the A6110 monitor into the prepared slot and press it with light pressure into the plug

connector.

3. Hand tighten the two anchoring screws on the front panel to secure the monitor.

Any other information, e. g. shielding and grounding, configuration of the monitor, etc., can be

found in the direction for use “Shaft Vibration Monitor A6110”, order number: 6110−90001.

1.6 Technical Data

Only information with tolerances and limit values are considered as binding data. Data without

tolerances or error limits are provided as information only. We reserve the right to make technical

changes − particularly to the software.

All of the following information applies uniformly for channel 1 and channel 2, if not otherwise

specified.

1.6.1 Signal conditioning

Two separate signal inputs for channel 1 and channel 2 with uncoupled signal conditioning.

Measured value inputs

Differential voltage amplification inputs, non−reactive, open−circuit and short−circuit proof.

Channel 1 z8: SENS1H (+); z10: SENS1L (− Signal)

Channel 2 d8: SENS2H (+); d10: SENS2L (− Signal)

Input nominal range

−1,0 ... −22.16 V

Limit range 0 ... −30 V DC

Input resistance > 100 kΩ