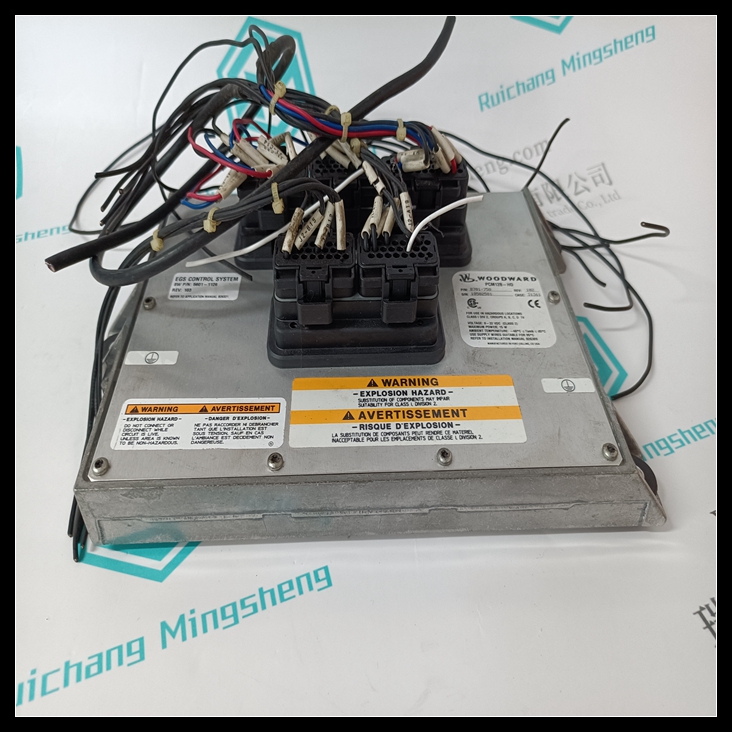

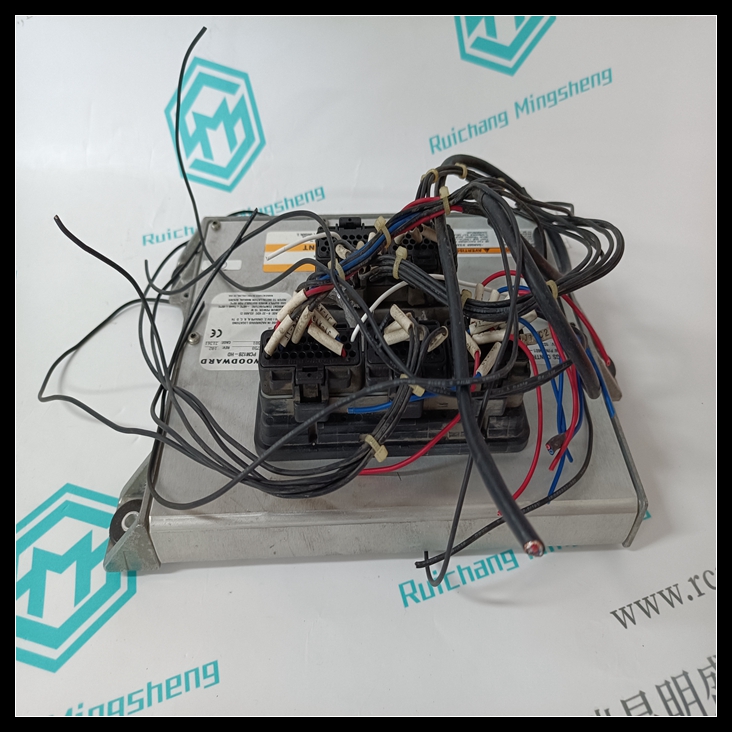

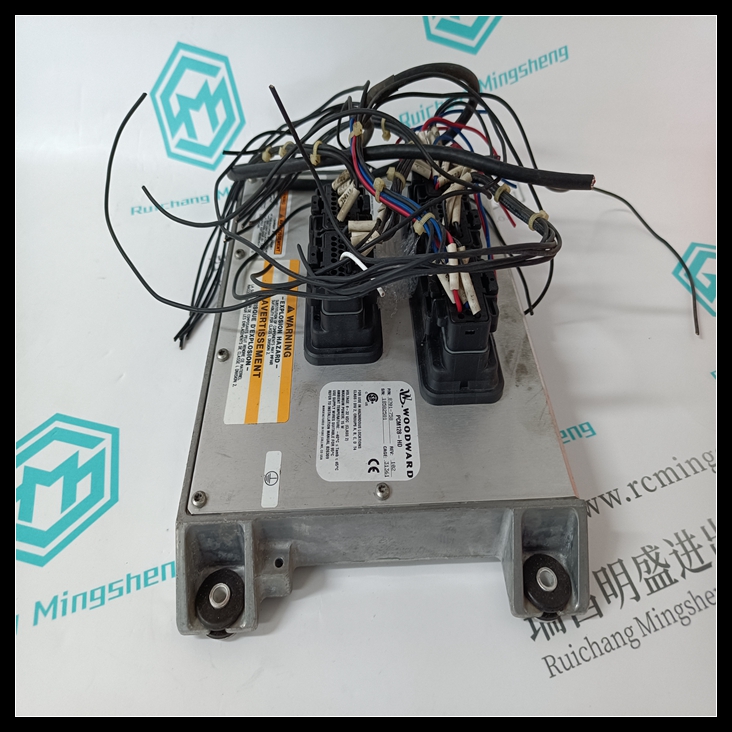

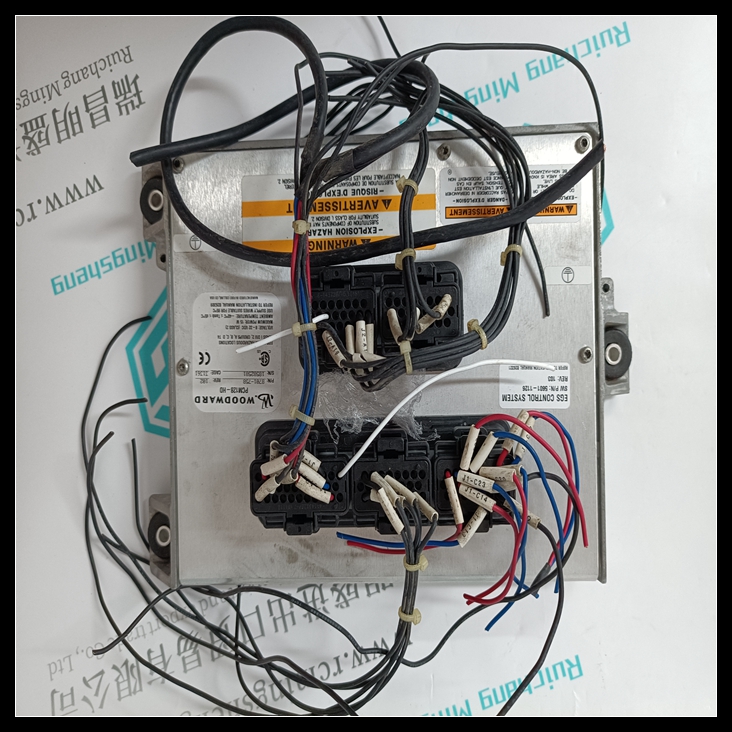

WOODWARD 5601-1126伺服放大器,5601-1126调速器

裂解反应主要过程是烃和蒸汽混合物在裂解炉中进行高温热裂解,形成富含乙烯和其他烯烃气体的混合物,同时副产粗裂解汽油和燃料油。

其他副产品包括丙烯和混合C4、氢气(用于装置内的加氢反应)和甲烷(用作燃料气)。装置内部生产的乙烷和丙烷,回到气体原料裂解炉裂解再循环利用,以增加乙烯产率。WOODWARD 5601-1126伺服放大器

裂解反应需要的热量主要由裂解炉底部烧嘴燃烧产生的辐射热提供,燃料主要有冷箱分离出的甲烷、氢气、液化石油气(LPG)和天然气。烧嘴全部采用自然通风的低氮氧化物型底部烧嘴,燃烧所需的氧气通过环境空气提供。每个烧嘴配置1台空气预热器,用装置多余的急冷水做热源,加热燃烧空气,提高燃料的燃烧效率,节省能耗。

乙烯裂解有3个关键变量,分别是停留时间、烃分压、反应温度,这些变量在工业裂解炉上对应4个主要操作参数:原料进料流量、稀释蒸汽流量、炉管出口压力、炉管出口温度(COT)。烃类原料裂解生成乙烯和丙烯的反应平衡,主要取决于反应的温度和时间,尤其取决于最高的反应温度或COT。

丙乙烯转化率是衡量裂解深度的主要指标,原料的产品分布与反应的剧烈程度有关。根据裂解原料的种类选取某种关键组分,并用它的转化率衡量整个原料的转化率,裂解深度越高,乙烯收率会越高,而丙乙烯比则会降低,甲烷和氢气的收率也会提高。WOODWARD 5601-1126伺服放大器

因此,可以通过调整裂解深度,在一定程度内可以调整各个主要裂解产品的收率分配比。另外,烃分压也是影响反应平衡的重要因素,分压髙的烃组分不利于生成乙烯产品,降低蒸汽比例或增大炉管出口压力会减小特定原料的乙烯收率,产品的产率分布主要通过控制COT实现。

1、 COT稳定与支路平衡优化控制power. It also makes it possible for manufacturers to choose the standard embedded system structure for design, get rid of the limitations brought by the proprietary hardware structure system of traditional PLC, and make the system have richer functional prospects. The so-called openness is to adopt international standards or recognized industrial standards in product design, component selection, network communication, operating system, monitoring and display. Thinking of standardization at all times can make the products of different manufacturers compatible, interchangeable and connected to the same network. Industrial Ethernet is such a standard. Since its appearance in 1975, the market share of Ethernet has been as high as 80%. There is no doubt that Ethernet is the leading network in the field of LAN (local area network). Ethernet can be divided into many levels. Generally, it is not necessary to use Ethernet for simple control