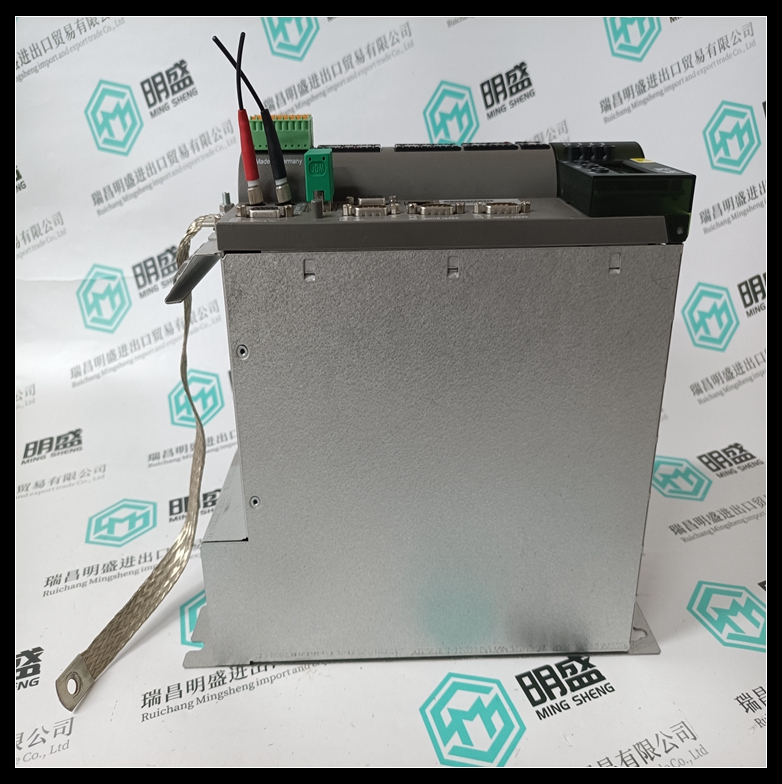

ELAU C600/10/11/1/00电机,C600/10/11/1/00使用手册

投用性能控制后,主风机组静叶由38.8度关到了28.8度,防喘阀总的输出由有11.3%关到了1.5%,主电机功率由17398KW降到了8973KW,主风总管流量波动范围在30NM3/min之内。不仅稳定了装置,而其每小时节能9000KW,经济效益非常可观。

9.备风机组投用性能控制效果分析

图9-1备风机性能控制工艺趋势

由图9-1所示,各曲线含义分析如下:

绿色曲线是总管流量的设定值;

红色曲线是总管流量的实测值;ELAU C600/10/11/1/00电机

黄色曲线是投用主风流量性能控制标志;

白色曲线是防喘阀的输出值;

蓝色曲线是防喘振盘旋点;

紫色曲线是防喘振的实际工作点;

浅蓝色曲线是备风机组静叶输出值;

粉色曲线是备电机功率;

可以看出,投用性能控制后,备风机组在某一时段检测到总管流量下降后,静叶由51.0度开到了57.0度,主电机功率由15594KW升到了15816KW,C600/10/11/1/00使用手册主风总管流量波动范围在30NM3/min之内。后来工艺人员发现是因往装置的安全阀故障自动打开了,如果当时没有投用性能控制,此事将会造成主风低流量,切断进料。此项功能挽救了装置非计划停车,创造了非常可观的经济效益。

10.结束语

与传统催化裂化的操作方式由操作人员手动操作完成主备风机的切换,自动切换控制更加平稳可靠、高效安全、人性化,同时杜绝了误操作的可能,从而保证了工艺系统平稳操作的要求。 and adaptive PID, all I know is to use the corresponding control algorithm to adjust the PID parameters in time. Let's take an example. The traditional PID algorithm formula is: ⊿ U (n) = KP [e (n) - E (n-1)] + KIE (n) + KD [e (n) - 2e (n-1) + e (n-2)] U (n) = ⊿ U (n) + U (n-1) e (n), e (n-1), e (n-2) is the deviation between the three set values in history and the process value. This is an incremental PID formula (if anyone doesn't understand what formula increment is, hehe, it may be mentioned later that my writing level is limited and I can't organize the content. Besides, where I think and write, hehe, see the cold). The so-called new PID controller is to use those advanced control laws to properly adjust KP, Ki and Ke according to the difference of E (n). As for how to adjust, hehe, it's too wordy, and it's not what this content should introduce. (the key is that I don't know, hehe, laugh). The great Xia who needs these functions should be my predecessors.